Homogeneous catalytic hydrogenation method for styrene-isoprene-styrene triblock copolymer

A technology of isoprene and homogeneous catalysis, applied in the field of hydrogenation of thermoplastic elastomers, to achieve good hydrogenation selectivity, improve catalyst efficiency, and simple and easy experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

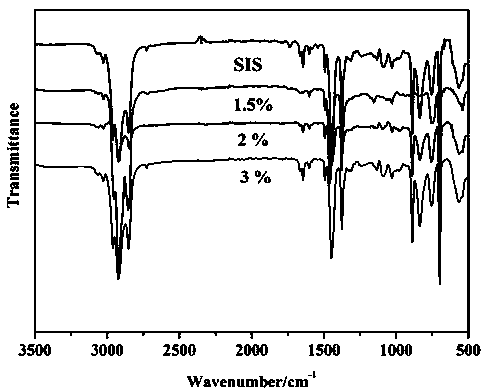

Embodiment 1

[0031]Three kinds of SIS glue solutions with different mass fractions were prepared, and the variation range was 0.5%-3%. The relative content of the catalyst added under each glue solution mass fraction remained unchanged, and the nickel content was used as the standard to set 0.1-1mmol / g SIS , wherein the molar ratio of Al / Ni is 2-8, the hydrogenation pressure is 1MPa-5MPa, the hydrogenation temperature is 40°C-100°C, and the reaction time is 1h-5h. The resulting product is tested by infrared, and the experimental results are as attached figure 1 As shown, the degree of hydrogenation under each glue mass fraction is shown in the table below.

[0032]

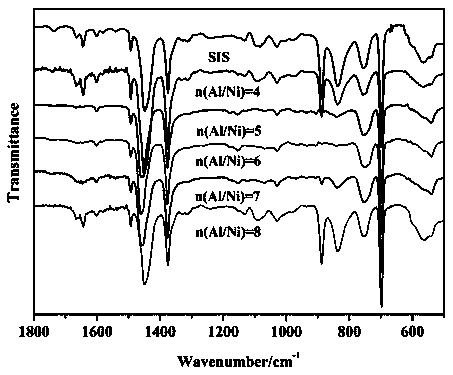

Embodiment 2

[0034] Prepare the SIS glue solution of 1.5w%, change the molar ratio scope of Al / Ni substance in 2-8, other reaction conditions are as embodiment 1, experimental infrared test result is as attached figure 2 As shown, the resulting degree of hydrogenation is shown in the table below.

[0035]

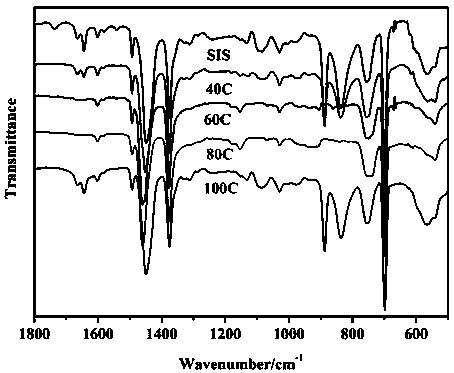

Embodiment 3

[0037] Prepare 1.5w% SIS glue, change the hydrogenation temperature in the range of 40°C-100°C, other experimental conditions are as in Example 1, and the experimental infrared test results are as attached image 3 Shown, the degree of hydrogenation obtained at each hydrogenation temperature is shown in the table below.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com