Coal pile humidification belt

A wet belt and coal pile technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of inaccurate watering, insufficient water, and muddy yard, so as to reduce the muddy area, promote cleanliness, and facilitate transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

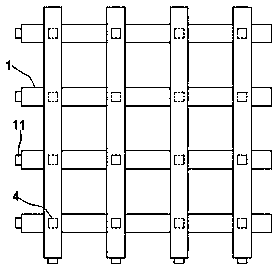

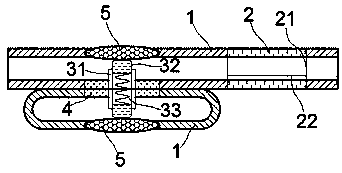

[0018] exist figure 1 , figure 2 In the shown embodiment, the coal pile humidification belt includes a hollow belt body 1, and the belt body 1 is in the shape of a flat strip; one end of the belt body 1 is installed with a water inlet valve 11, and the other end is sealed; The surface of the belt body 1 is equidistantly provided with sprinkler rings 2, and each sprinkler ring 2 is provided with a water spray hole communicating with the belt body 1; a limit grid plate 21 is arranged at both ends of the sprinkler ring 2, and A sealing sheet 22 is slidably installed between the limit grid plates 21, and the density of the sealing sheet 22 is greater than that of the water body; an interactive module is also installed equidistantly on the surface of the belt body 1, and the interactive module includes a normally closed communication module. Valve and positioning magnetic sheet 4; the magnetic pole connection direction of the positioning magnetic sheet 4 is perpendicular to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com