Method for promoting electrical conduction between metallic components and composite materials

A metal parts, electrical conductivity technology, applied in chemical instruments and methods, conductive coatings, vehicle parts, etc., can solve problems such as reducing the mechanical properties of fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

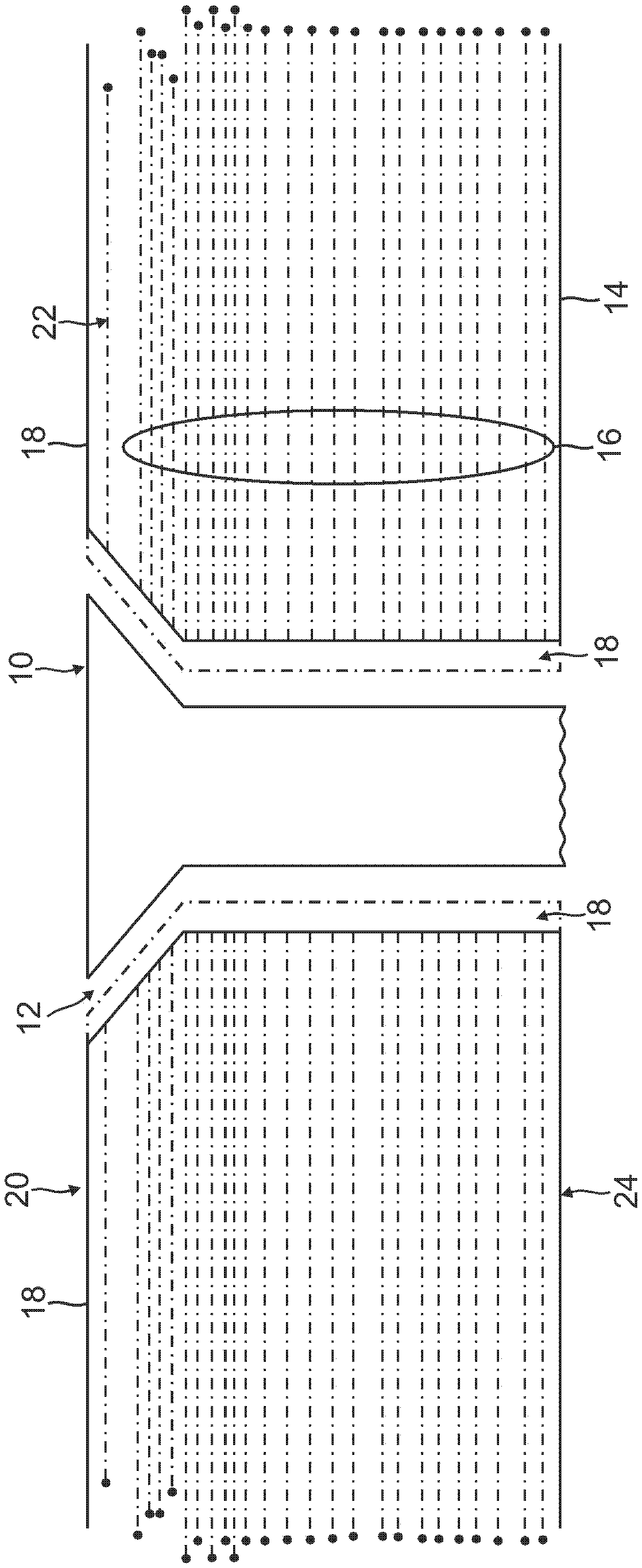

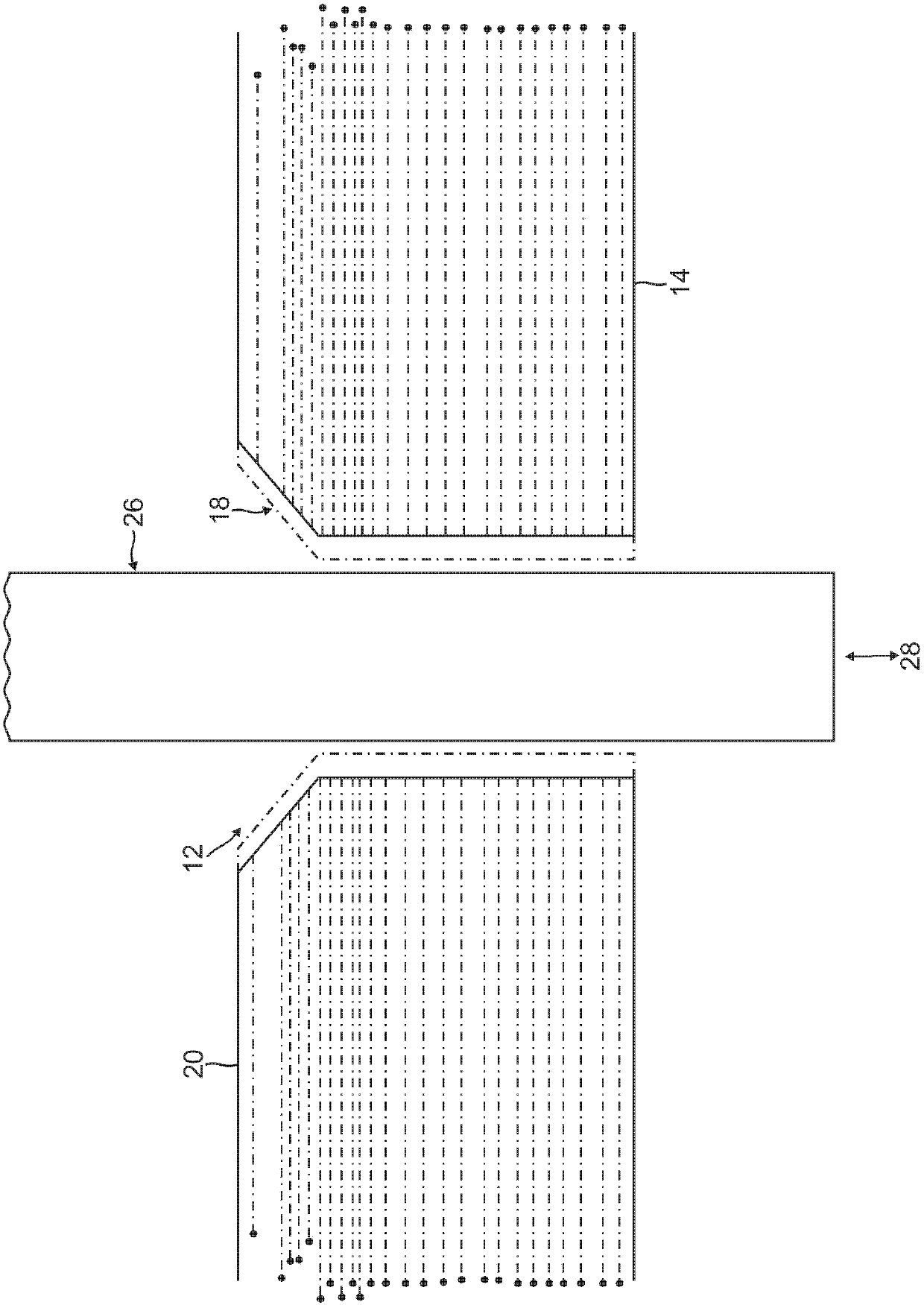

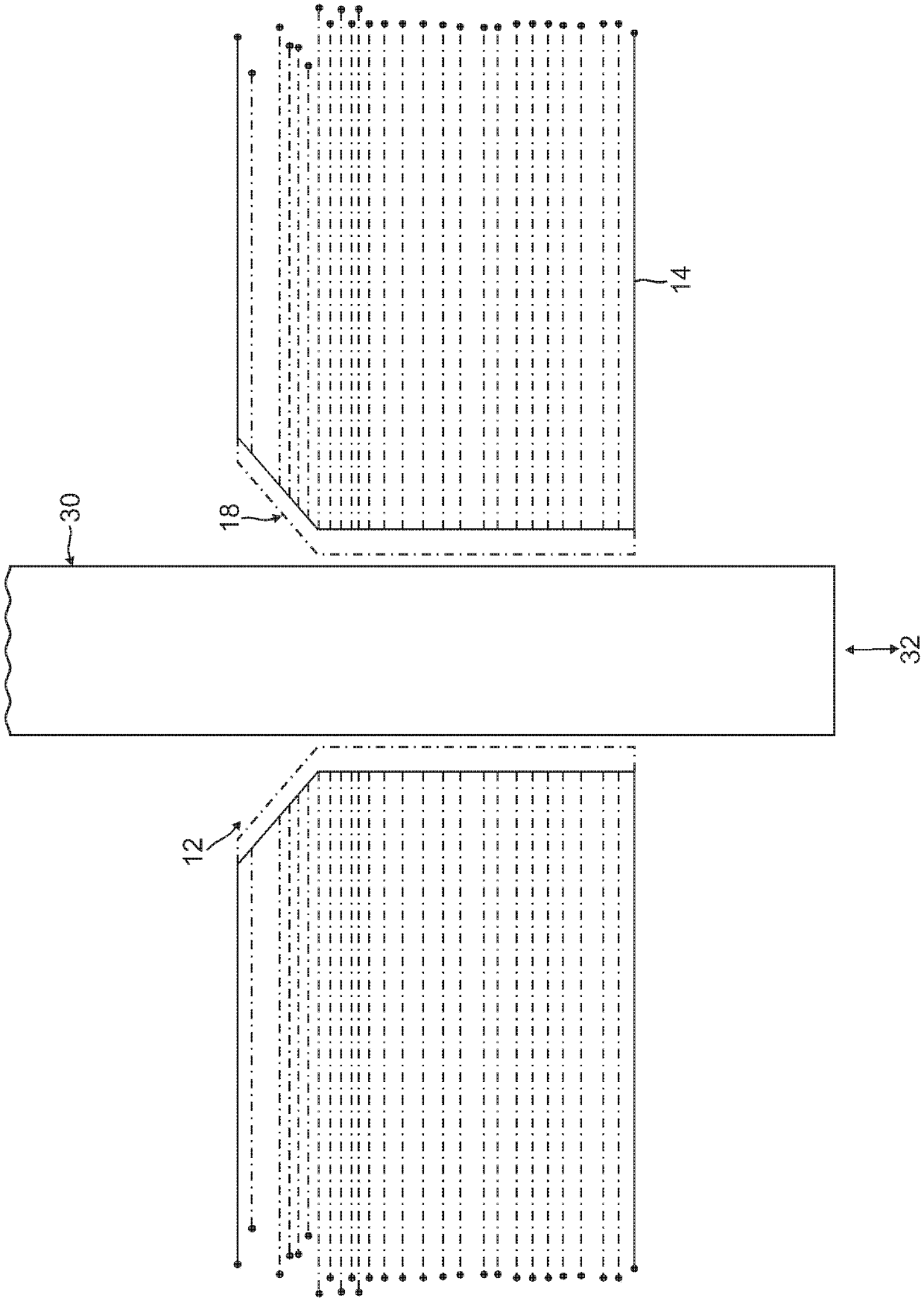

[0068] 1. A method of enhancing conductance comprising:

[0069] The composite body is coated with an adhesive layer comprising a conductive material, wherein when the metal part is attached to the composite body, the metal part is electrically connected to the conductive material of the adhesive layer.

[0070] 2. The method according to clause 1, wherein the composite body is an aircraft or other vehicle structure composed of a composite material formed from carbon fiber reinforced polymer (CFRP), the metal parts being fasteners, and electrically connected to the adhesive layer Metal parts of conductive material that form part of a lightning strike protection system, electromagnetic effects (EME) management system, or grounding system.

[0071] 3. The method of clause 1, wherein the metal part comprises a sleeve, washer, or other element placed at the interface between the fastener and the composite body.

[0072] 4. The method of clause 1, wherein the adhesive layer compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com