Welding method applied to aluminiferous oxide dispersion strengthened ferrite / martensitic steel

A technology of dispersion strengthening, martensitic steel, applied in welding equipment, welding medium, welding equipment, etc., can solve problems affecting welding quality and other problems, and achieve the effect of excellent mechanical properties and excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

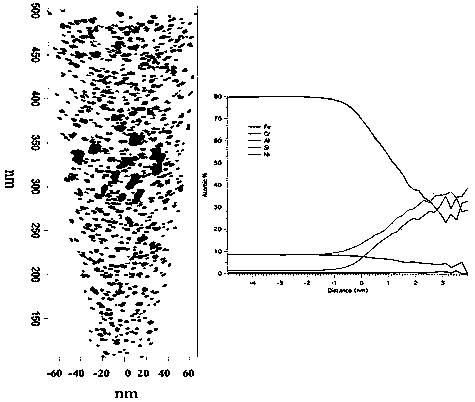

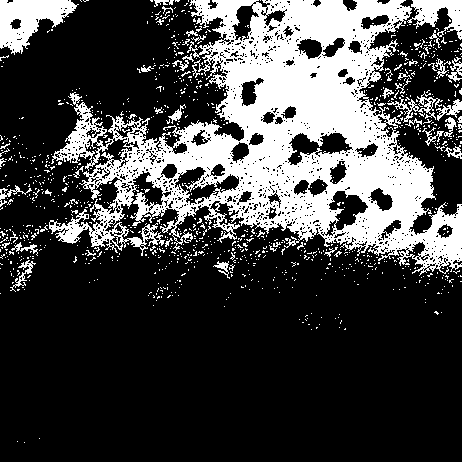

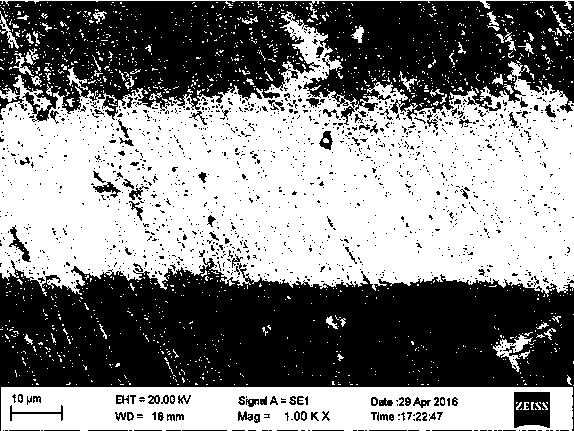

Image

Examples

Embodiment 1

[0026] material selection:

[0027] (1) The composition of the aluminum-containing oxide dispersion strengthened ferrite / martensitic steel to be welded is 8.5%Cr, 1.2%W, 0.2%V, 0.2%Mn, 3.5%Al, 0.5%Zr, 0.35% Y2O3, the purity of the above raw materials is 99.9%, the content of C and N is less than 0.1%, the rest is Fe, the above are all mass percentages; the preparation method is mechanical alloying and hot isostatic pressing;

[0028] (2) The composition of the middle layer foil is 16wt.%Ni, 8.5wt.%Cr, 3wt.%B, 2wt.%Si, 0.08wt.%C, the purity is 99.9%, the rest is Fe; the thickness is 15 μm ;

[0029] The specific welding process is:

[0030] (1) Surface treatment

[0031] The aluminum-containing oxide dispersion-strengthened ferrite / martensitic steel surface to be welded and the intermediate layer foil are respectively polished, and then placed in an acetone solution for ultrasonic cleaning for 5 to 10 minutes, and dried with cold air to obtain the pretreated Aluminium-containing oxide...

Embodiment 2

[0036] material selection:

[0037] (1) The composition of the aluminum-containing oxide dispersion strengthened ferrite / martensitic steel to be welded is 9%Cr, 1.8%W, 0.3%V, 0.2%Mn, 4.5%Al, 0.2%Hf, 0.4% Y2O3, the purity of the above raw materials is 99.9%, the content of C and N is less than 0.1%, the rest is Fe, the above are all mass percentages; the preparation method is mechanical alloying and hot isostatic pressing;

[0038] (2) The middle layer foil, the composition is 12wt.%Ni, 9wt.%Cr, 3wt.%B, 2wt.%Si, 0.06wt.%C, the purity is 99.9%, the rest is Fe, the thickness is 20μm;

[0039] The specific welding process is:

[0040] (1) Surface treatment

[0041] The aluminum-containing oxide dispersion-strengthened ferrite / martensitic steel surface to be welded and the intermediate layer foil are respectively polished, and then placed in an acetone solution for ultrasonic cleaning for 5 to 10 minutes, and dried with cold air to obtain the pretreated Aluminium-containing oxide dispersio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com