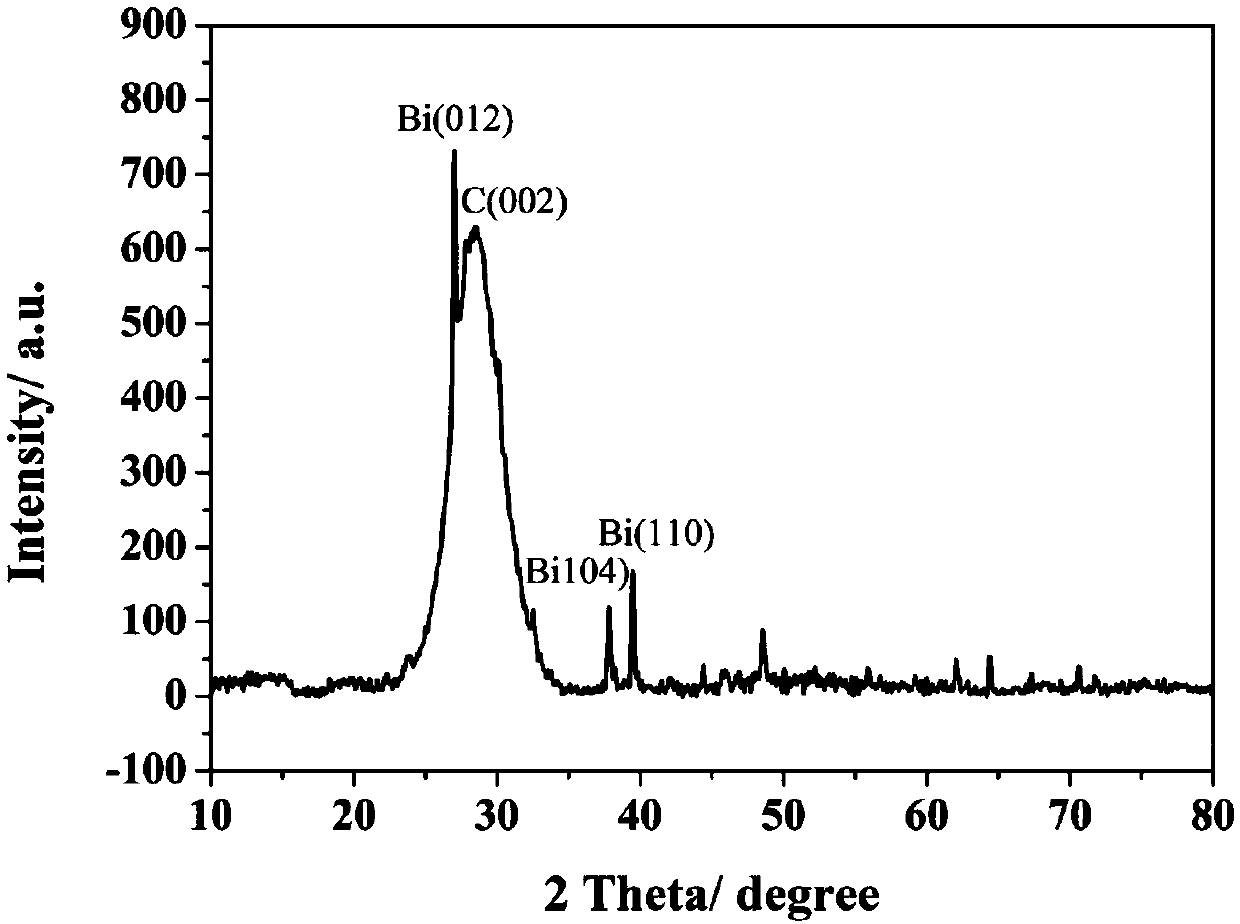

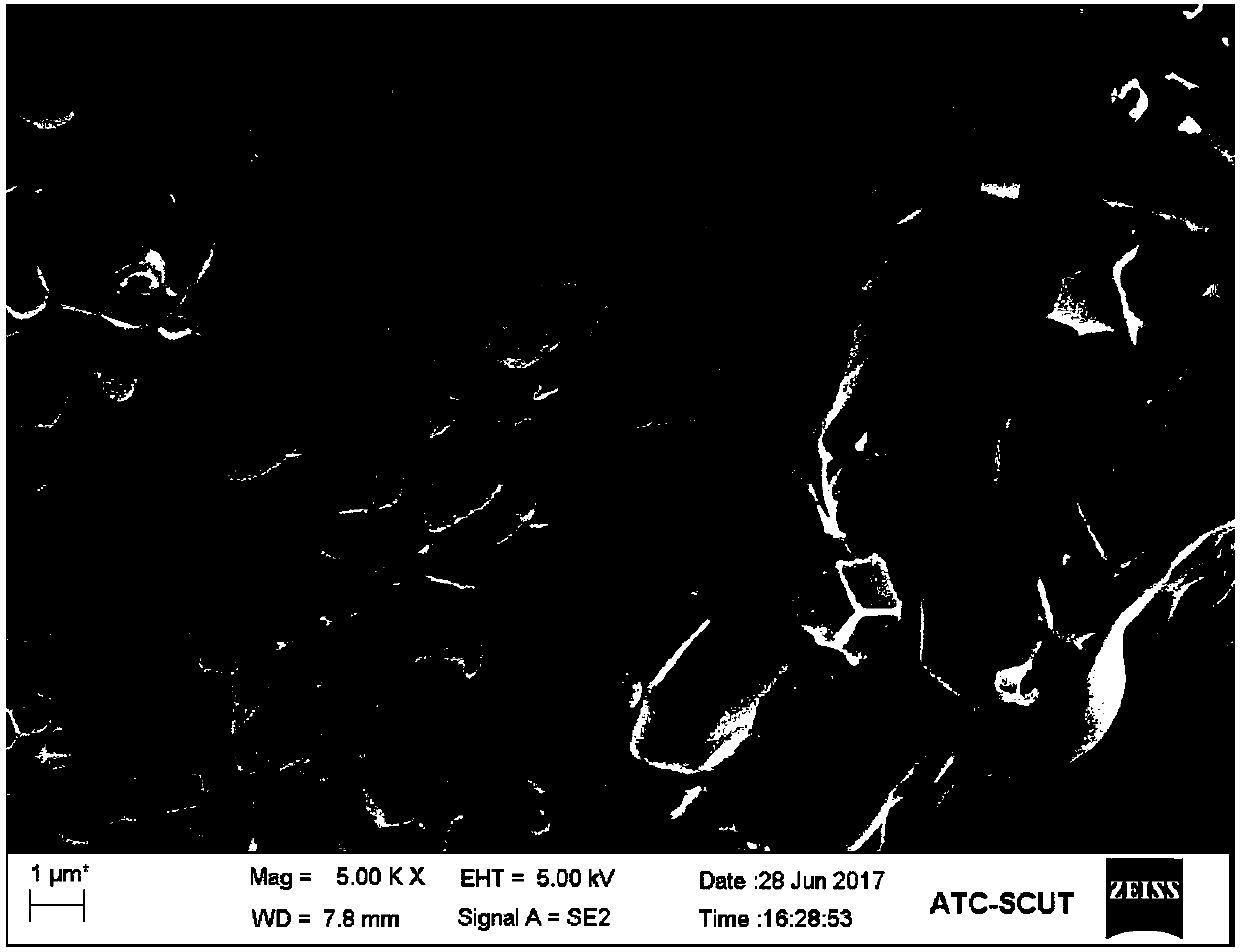

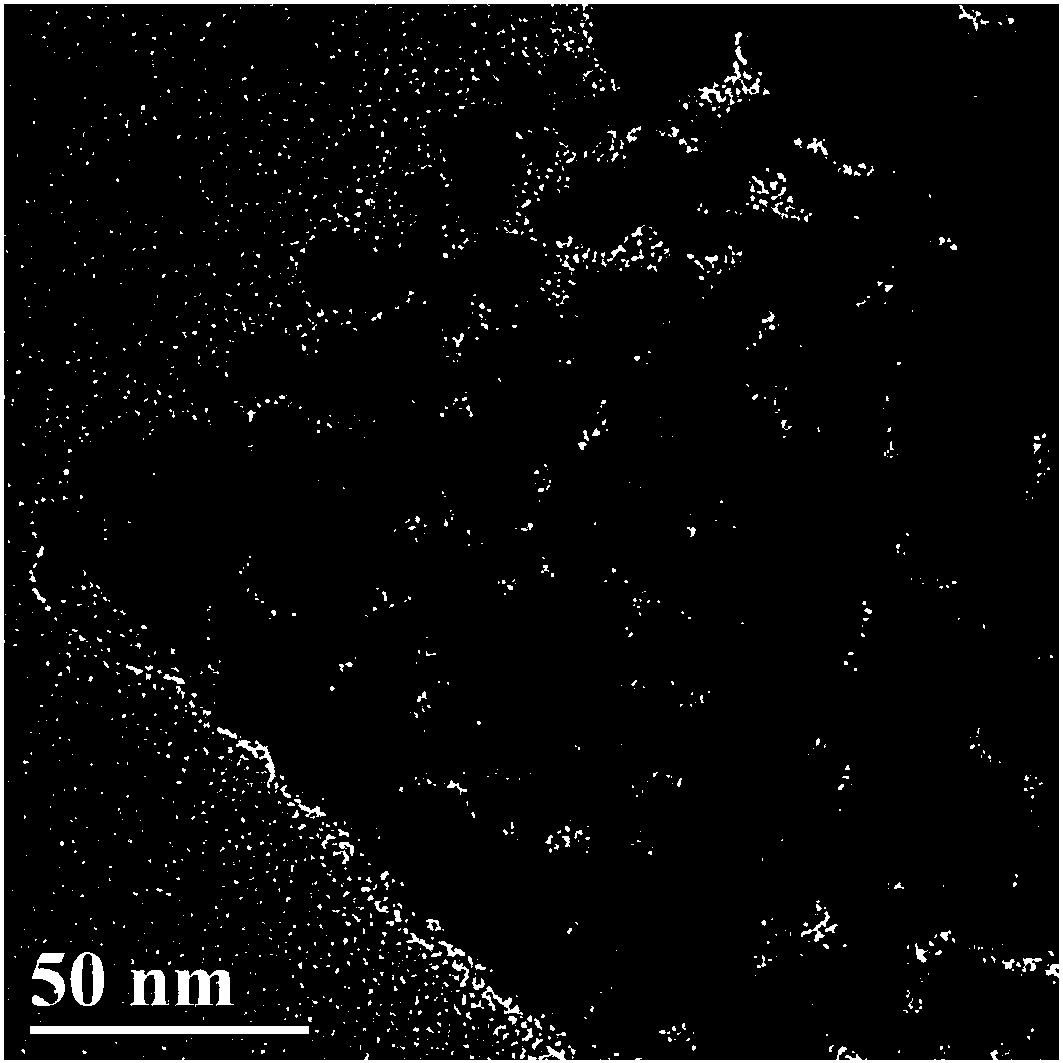

Porous and high-specific-surface-area bismuth-nanoparticle-modified nitrogen-doped carbon nanosheet material and a preparation method and application thereof

A high specific surface area, nitrogen-doped carbon technology, applied in the field of nanomaterials, nitrogen-doped carbon nanomaterials, can solve the problems of small surface area, increased cost, cumbersome steps, etc., to achieve stable structure and performance, suitable for large-scale production, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a nitrogen-doped carbon nanosheet material modified by bismuth nanoparticles with a porous surface and high specific surface area, comprising the following steps:

[0036] (1) Use 0.5 g of polyvinylpyrrolidone K28 as a carbon source and nitrogen source, add 50 mL of ethylene glycol (carbon source) to fully dissolve, and obtain a 0.01 g / L nitrogen source solution;

[0037] (2) Add 0.05 g of bismuth nitrate to the nitrogen source solution obtained in step (1), stir and adjust the pH value to 5.5 with acetic acid, at this time, the bismuth nitrate is completely dissolved to obtain a mixed solution;

[0038] (3) Place the mixed solution obtained in step (2) in an electric blast drying oven at 110°C for 14 hours until a pale yellow solid precursor is obtained;

[0039] (4) Grind the obtained light yellow solid precursor into a fine powder and put it into a porcelain boat. Under the condition of nitrogen protection with a flow rate of 40mL / min, place it...

Embodiment 2

[0044] A method for preparing a nitrogen-doped carbon nanosheet material modified with bismuth nanoparticles with a porous surface and high specific surface area, specifically comprising the following steps:

[0045] With 1.0g of polyvinylpyrrolidone K30 as carbon source and nitrogen source, add 10mL of water to fully dissolve in the beaker, then add 5g of bismuth acetate to the beaker, stir and adjust the pH value of the mixed solution to 4.5 with nitric acid. Bismuth is completely dissolved. Put the prepared solution in an electric blast drying oven at a temperature of 130°C for 12 hours until a light yellow solid precursor is obtained. Grind the obtained light yellow solid precursor into a fine powder and put it into a porcelain boat. At a flow rate of 30mL / min nitrogen and argon mixed gas protection conditions, placed in a tube furnace for heating and roasting. The calcination process was heated from room temperature to 900 °C at a heating rate of 8 °C / min, then kept at ...

Embodiment 3

[0050] A method for preparing a nitrogen-doped carbon nanosheet material modified with bismuth nanoparticles with a porous surface and high specific surface area, specifically comprising the following steps:

[0051] With 5.0g of polyvinylpyrrolidone K25 as carbon source and nitrogen source, add 100mL of water to fully dissolve in the beaker, then add 10g of bismuth acetate in the beaker, stir and adjust the pH value of the mixed solution to 5.0 with nitrous nitric acid, at this time Bismuth nitrate is completely dissolved. Put the prepared solution in an electric blast drying oven at a temperature of 120°C for 13 hours until a light yellow solid precursor is obtained, grind the obtained light yellow solid precursor to a fine powder and put it into a porcelain boat, at a flow rate of 60mL / min nitrogen and argon mixed gas protection conditions, placed in a tube furnace for heating and roasting. The calcination process was heated from room temperature to 800 °C at a heating ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com