Nougat and preparation method thereof

A technology of nougat and nougat, applied in confectionery, confectionary industry, food science, etc., can solve problems such as poor taste, narrow applicable population, sticky teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

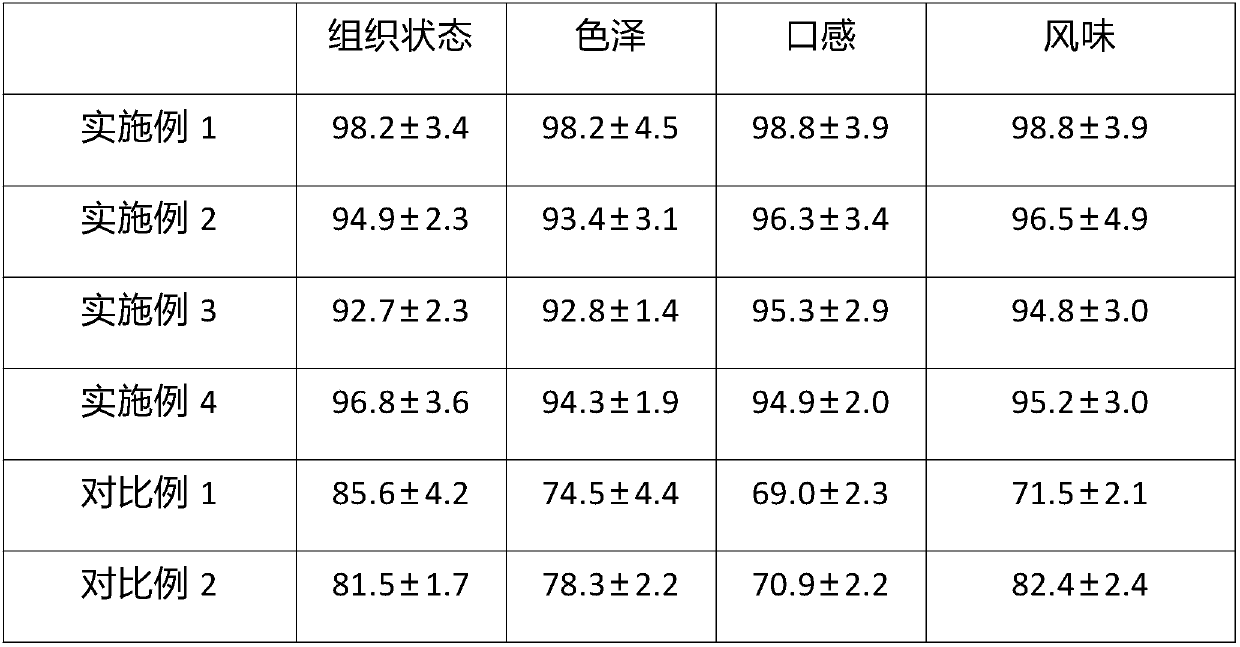

Embodiment 1

[0022] A kind of nougat, by weight, comprising the following components: 150g of coconut milk, 5kg of glucose syrup, 22kg of peanut grains, 7kg of cream, 25kg of white granulated sugar, 6kg of trehalose, 60g of protein, 12g of edible salt, 55g of shiitake mushroom powder, Tremella fine powder 25g, kelp fine powder 12g, brown algae fine powder 2g, centipede algae fine powder 2g, dulse palmate fine powder 4g.

[0023] This nougat is made by following preparation method:

[0024] S1: Sugar preparation solution: mix white granulated sugar and edible salt, add water to mix according to the material-to-liquid ratio of 1:1, heat to dissolve, filter, heat up to 85°C, keep for 20 minutes, add trehalose, mix well, cool down, and obtain sugar solution ;

[0025] S2: Syrup production: According to the temperature gradient of 55°C, 70°C, 88°C, 95°C, 110°C, and 89°C, the temperature gradient is used to cook the syrup, each temperature change must be completed within 15 minutes, and the tem...

Embodiment 2

[0032] A kind of nougat, comprising the following components by weight: 100g of coconut milk, 5kg of glucose syrup, 20kg of peanuts, 5kg of cream, 25kg of white granulated sugar, 5kg of trehalose, 50g of protein, 10g of edible salt, 50g of shiitake mushroom powder, Tremella fine powder 25g, kelp fine powder 10g, brown algae fine powder 1g, centipede algae fine powder 2g, dulse palmate fine powder 1g.

[0033] This nougat is made by following preparation method:

[0034] S1: Sugar preparation solution: mix white granulated sugar and edible salt, add water to mix according to the ratio of material to liquid 1:2, heat to dissolve, filter, heat up to 90°C, keep for 15 minutes, add trehalose, mix well, cool to obtain sugar solution ;

[0035] S2: Syrup production: According to the temperature gradient of 65°C, 75°C, 92°C, 100°C, 120°C, and 108°C, the temperature gradient is used to cook the syrup, each temperature change must be completed within 10 minutes, and the temperature sho...

Embodiment 3

[0042] A kind of nougat, comprising the following components by weight: 250g of coconut milk, 7kg of glucose syrup, 30kg of peanut grains, 10kg of cream, 35kg of white granulated sugar, 10kg of trehalose, 100g of protein, 50g of edible salt, 150g of shiitake mushroom powder, Tremella fine powder 35g, kelp fine powder 30g, brown algae fine powder 5g, centipede algae fine powder 4g, dulse palmate fine powder 5g.

[0043] This nougat is made by following preparation method:

[0044] S1: Sugar preparation solution: mix white granulated sugar and edible salt, add water to mix according to the ratio of material to liquid 1:2, heat to dissolve, filter, heat up to 90°C, keep for 15 minutes, add trehalose, mix well, cool to obtain sugar solution ;

[0045] S2: Syrup production: According to the temperature gradient of 60°C, 72°C, 90°C, 98°C, 115°C, and 95°C, the temperature gradient is used to cook the syrup. Each temperature change should be completed within 12 minutes, and the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com