Lubricants with titanium and/or tungsten and their use for improving low speed pre-ignition

A low-speed, lubricating oil composition technology, applied in the direction of engine lubrication, lubricating composition, additives, etc., can solve problems such as increased LSPI incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

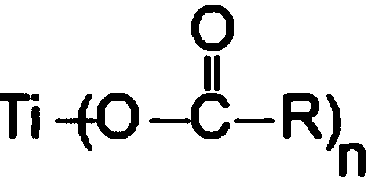

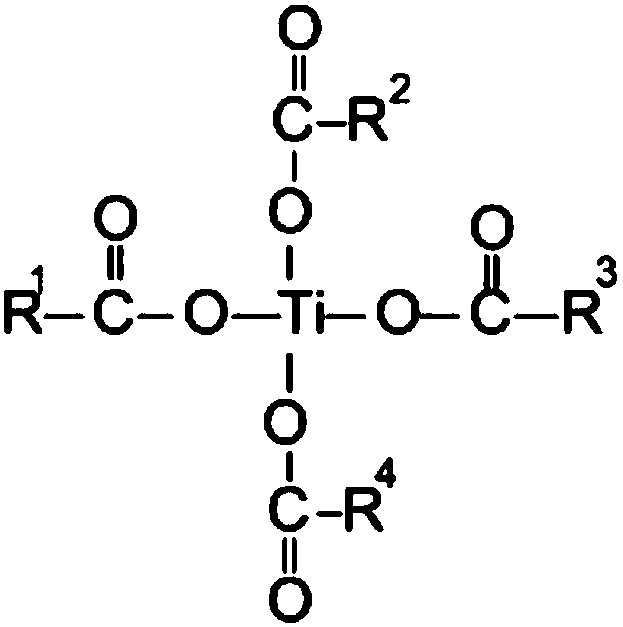

Method used

Image

Examples

example

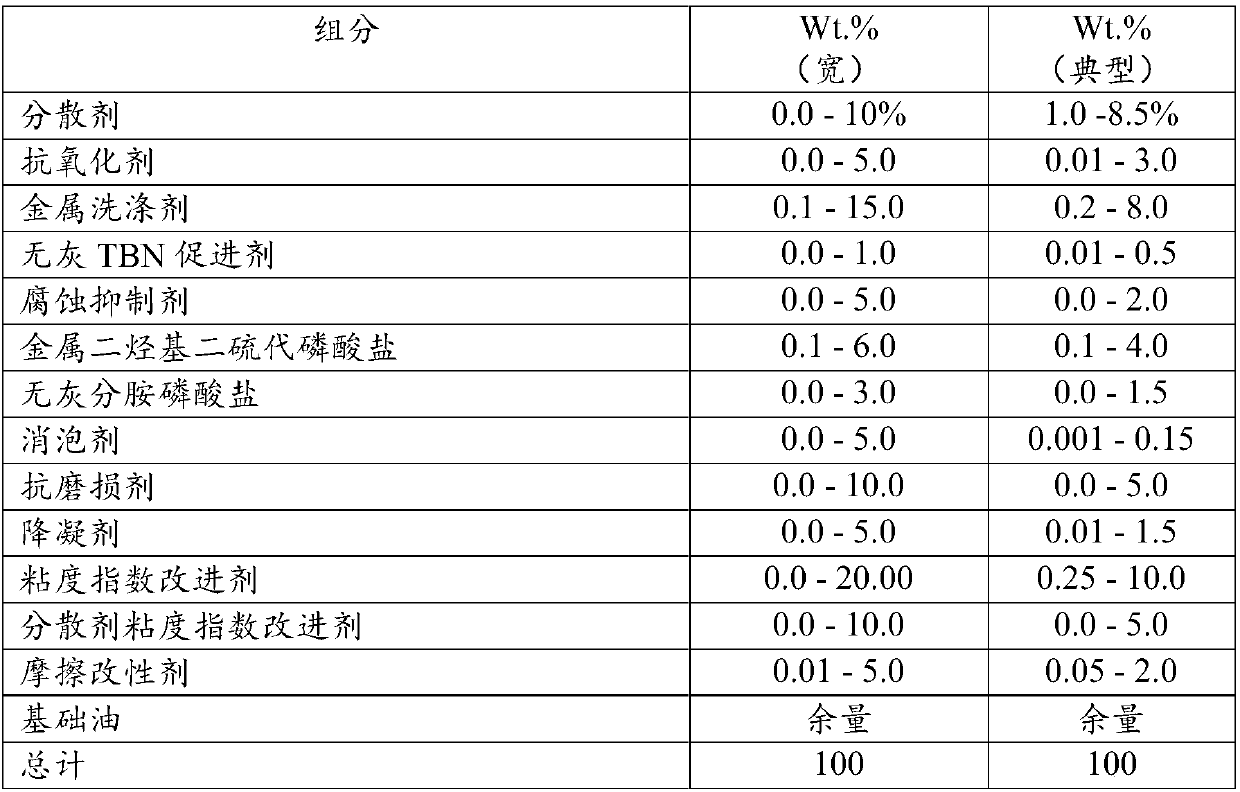

[0231] Fully formulated lubricating oil compositions containing conventional additives were prepared and the low rate preignition events of the lubricating oil compositions were measured. Each lubricating oil composition contained a major amount of base oil, a conventional base DI package, and a viscosity index improver, wherein the base DI package (lacking the viscosity index improver) comprised about 8 to 12% by weight of the lubricating oil composition. Base DI contained conventional amounts of dispersants, antiwear additives, defoamers and antioxidants, as shown in Table 3 below. Specifically, the base DI comprises a succinimide dispersant, a borated succinimide dispersant, a molybdenum-containing compound in an amount providing about 80 ppm molybdenum to the lubricating oil composition, an organic friction modifier, one or Various antioxidants and one or more antiwear agents (unless otherwise specified). The base DI package is also blended with about 5 to about 10 wt. % ...

example 1

[0247] The effect of varying amounts of titanium incorporation into lubricating oil compositions on the LSPI ratio was tested. A base formulation was used to test the combination of an overbased calcium-containing detergent ("OB") with a titanium-containing compound. Formulation R-1, as described above, contained as the sole detergent an overbased calcium-containing detergent in an amount to provide about 2400 ppmw Ca to the lubricating oil composition. Formulation R-2 contained slightly more calcium, and 100 ppm titanium.

[0248] Comparative formulation C-1 contained, as the sole detergent, an overbased calcium-containing detergent in an amount to provide about 1600 ppmw Ca to the lubricating oil composition. Comparative formulation C-2 contained an amount of overbased calcium-containing detergent to provide 2400 ppmw Ca to the lubricating oil composition. Formulation C-2 also contained the reaction product of titanium isopropoxide and neodecanoic acid in an amount to prov...

example 2

[0256] In this example the effect of including different sources of titanium in lubricating oil compositions was determined. Formulations R-1 and C-1 as described above in Example 1 were used for comparison purposes. In addition, Inventive Example I-2 is also the same as Example 1 in this Example 2. In each of the experimental compositions of Examples 2, 1-2, 1-5, and 1-6, the level of overbased calcium-containing detergent provided approximately 1575 ppmw Ca to the various lubricating oil compositions. Formulation 1-2 used the reaction product of titanium isopropoxide and neodecanoic acid as the titanium source. Formulation 1-5 used titanium isopropoxide as the titanium source. In formulation 1-6, a titanium-containing dispersant was used as the titanium source. The results are shown in Table 5.

[0257] table 5

[0258]

[0259] As shown in Table 5, each of the different titanium sources used in the lubricating oil compositions was effective in reducing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com