Modular heat dissipation structure of power supply and distribution load device

A heat dissipation structure and loader technology, which is applied in the construction parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., can solve time-consuming and labor-intensive problems, and achieve improved reliability, inheritability, and portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

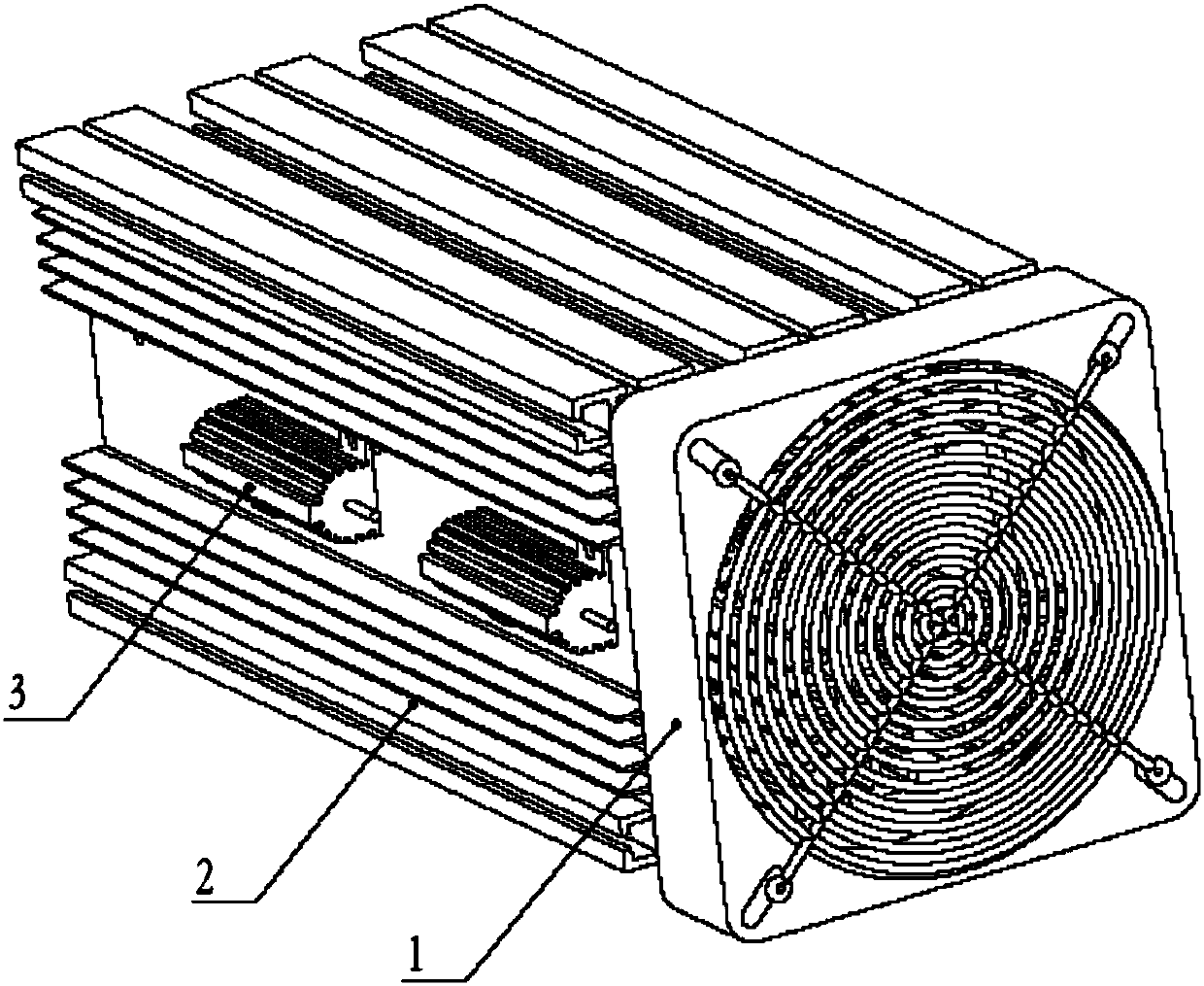

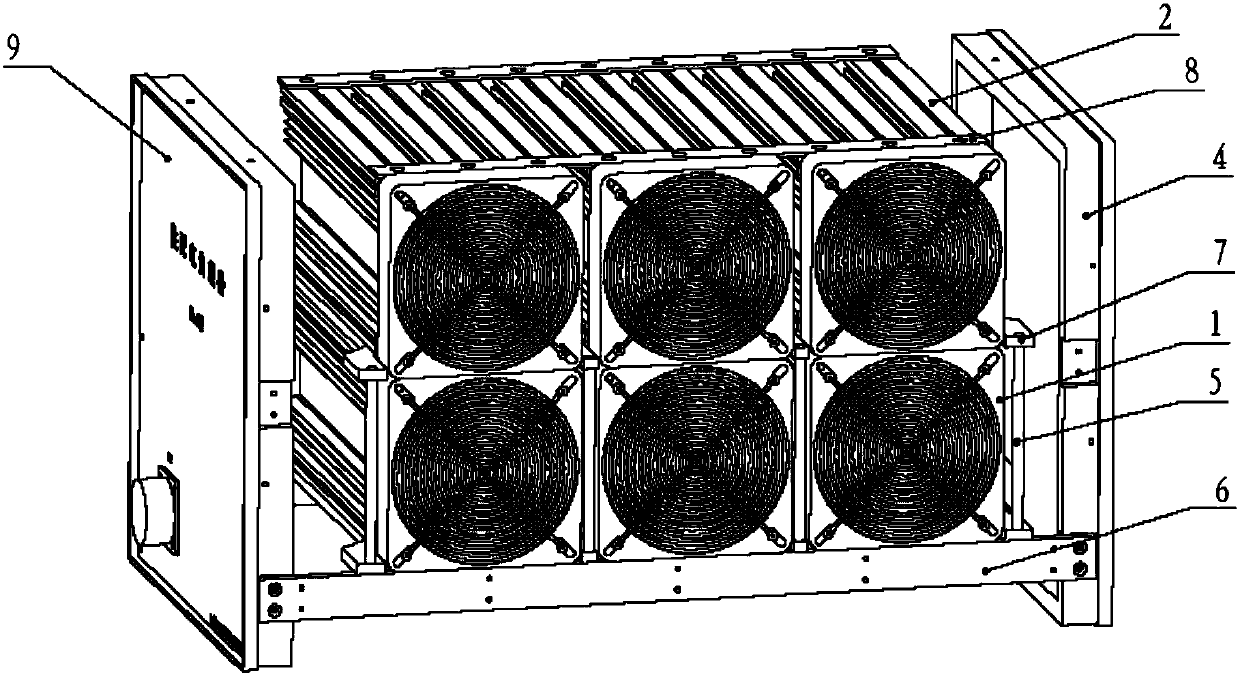

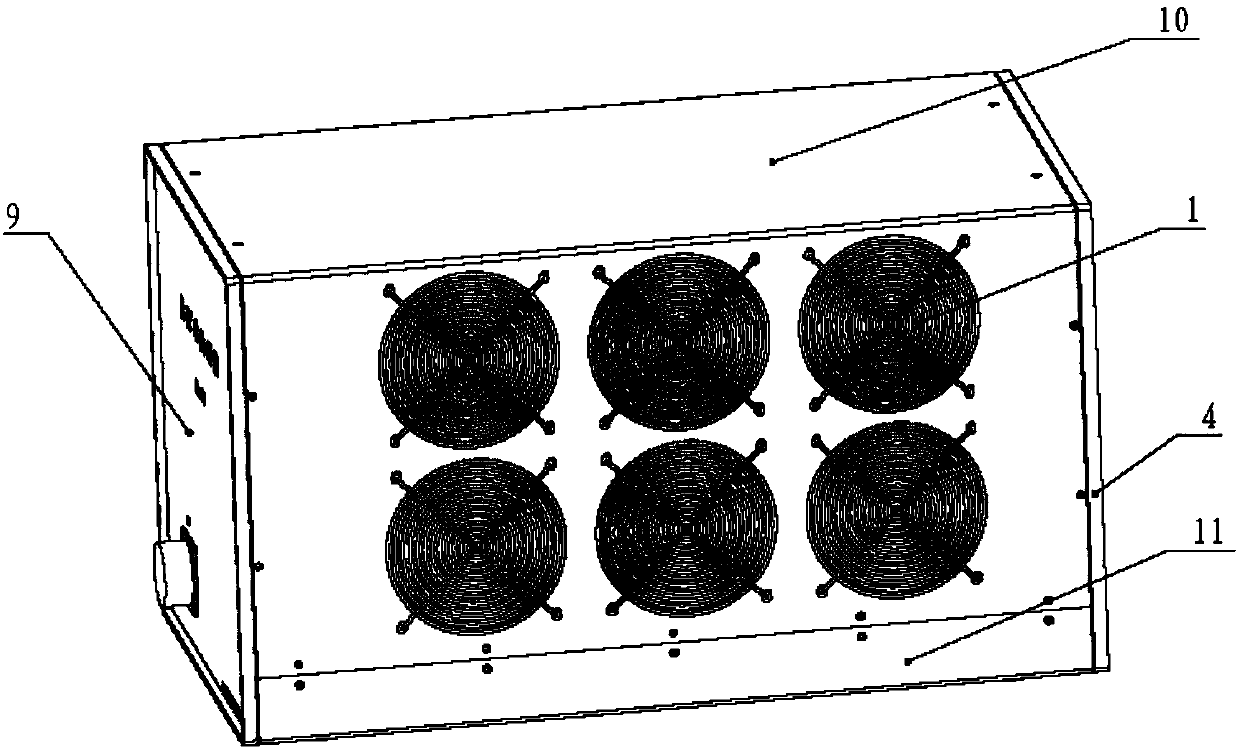

[0018] Such as figure 1 — Figure 4 As shown, the modular heat dissipation structure of the power supply and distribution load device of the present invention includes an axial flow fan 1, a radiator 2, a power resistor 3, a rear panel 4, a column 5, a support bar 6, a support plate 7, and a heat sink fixing bar 8. Front panel 9, upper cover 10 and lower cover 11; one side of the loader is equipped with an axial flow fan 1 for forced air cooling, and the other side is designed with a mesh outlet for air outlet.

[0019] The 28W power resistor 3 is fixed on the SRX-YDU radiator 2. Multiple radiators 2 are arranged vertically and fixed on the support plate 7 through the heat sink fixing strip 8; the column 5 is fixed between the two support plates 7; the support plate 7 is fixed on the support bar 6; the support bar 6 and the front panel 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com