Graphene heating film and production method thereof

A technology of a graphene heating film and a production method, which is applied in the application field of graphene materials, can solve the problems of peeling off of the surface insulating protective layer, layering of the graphene electric heating film, and difficulty in double-sided coating, and achieves no layering and electric heating. Efficient and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

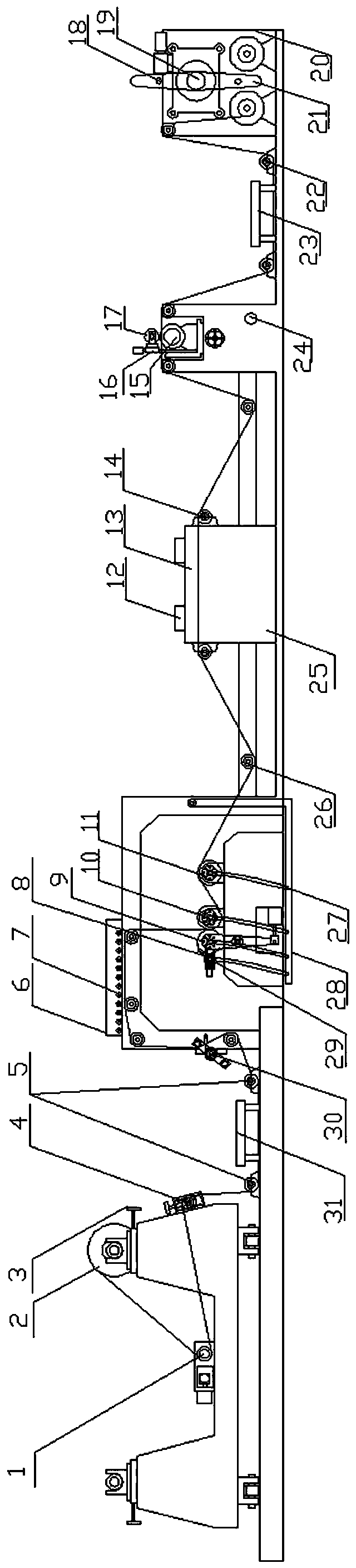

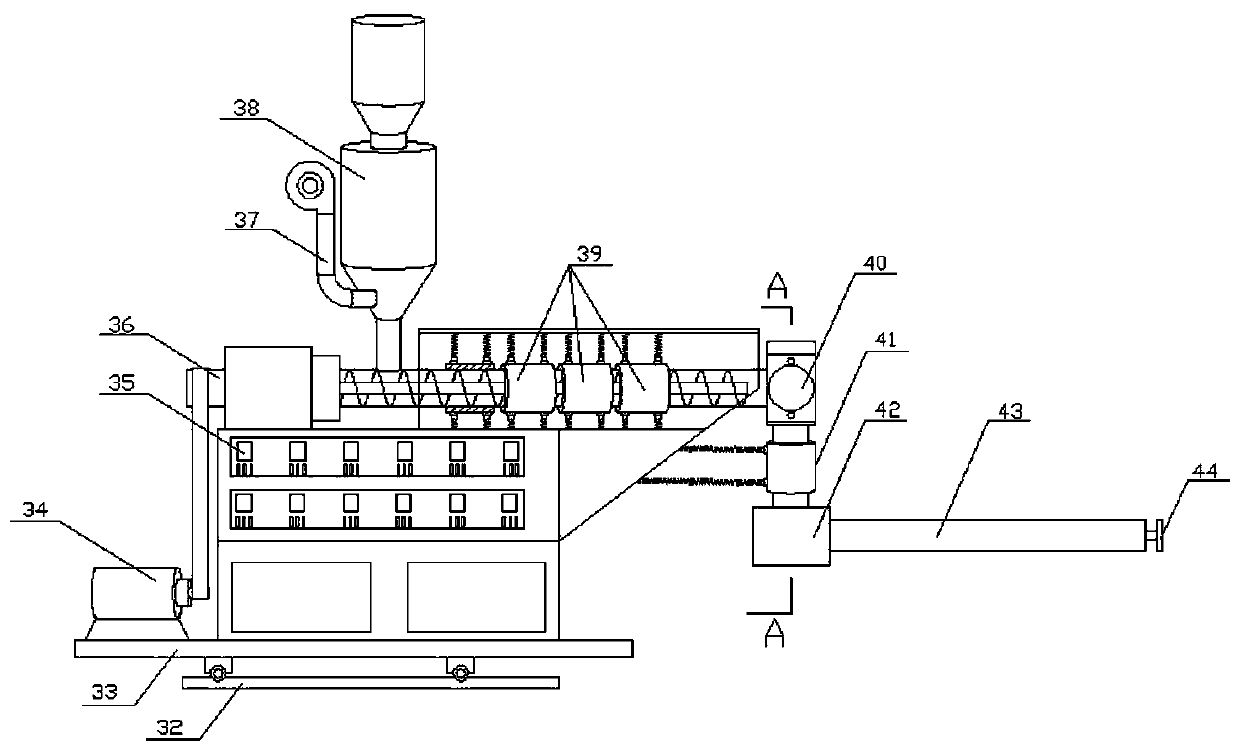

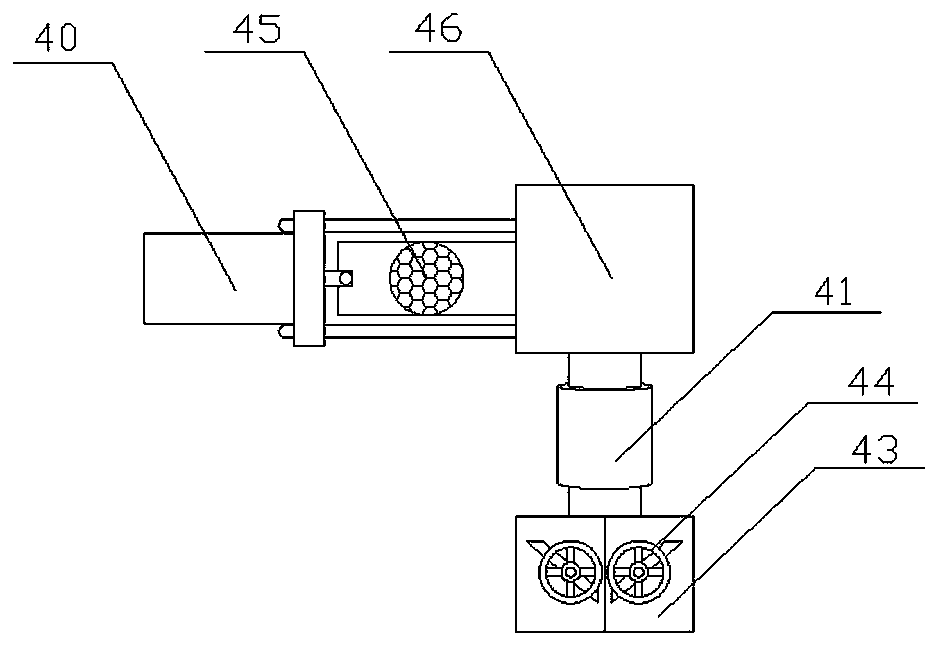

[0063] Such as Figure 1-9 as shown, figure 1 It is a schematic diagram of the overall structure of the present invention. figure 2 It is a structural schematic diagram of the film forming device of the present invention. image 3 for figure 2 Sectional schematic of part A-A. Figure 4 It is a structural schematic diagram of the coating device of the present invention. Figure 5 It is a structural schematic diagram of the ingredient mixing tank of the present invention. Figure 6 It is a structural schematic diagram of the tension adjusting device matched with the rapier loom in the present invention. Figure 7 It is the left view of the frame of the tension adjusting device in the present invention. Figure 8 It is a top view of the stand of the tension adjusting device in the present invention.

[0064] Figure 9 It is the rear view of the stand of the tension adjusting device in the present invention.

[0065]The graphene heating film of the present invention com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com