Quickly mounted prefabricated drainage ditch

A drainage ditch, fast technology, applied in the direction of waterway system, water supply device, sewer pipeline system, etc., can solve the problems of reducing the flow rate of water, increasing the area of water passing, rough inner wall, etc., and achieve rapid assembly and dismantling, installation and disassembly Convenience and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

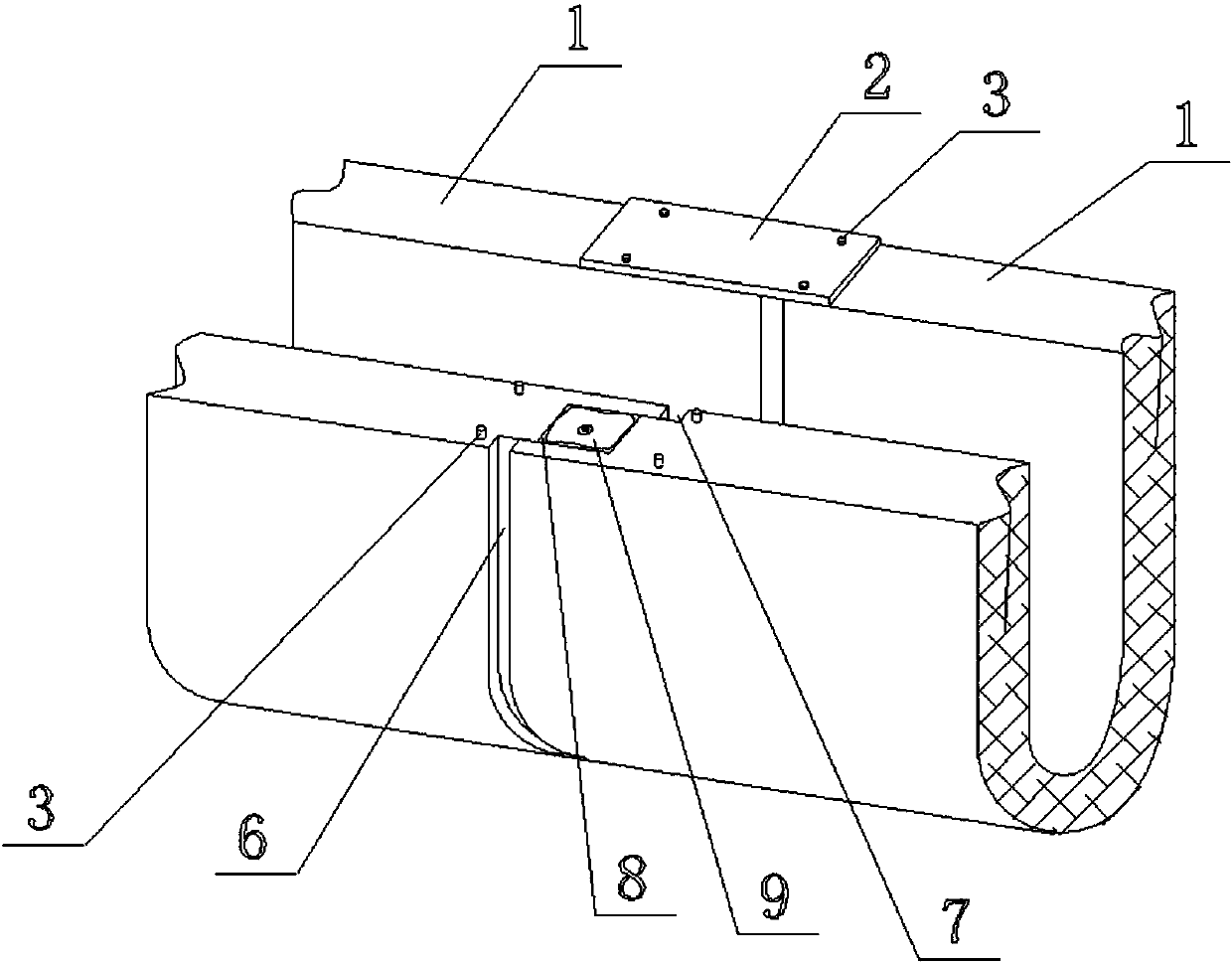

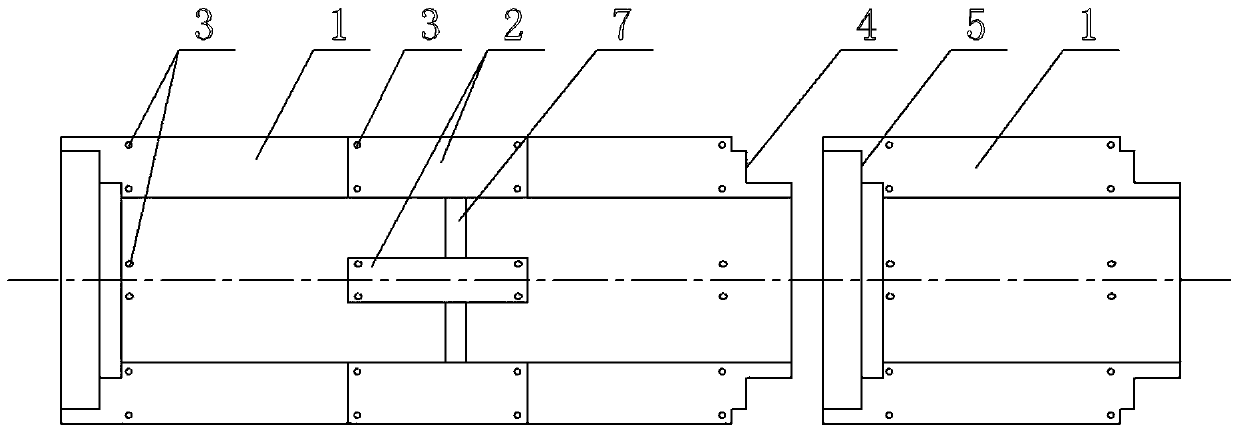

[0014] Example: such as figure 1 and figure 2 The quick-install prefabricated drainage ditch shown includes a plurality of U-shaped drainage ditch concrete unit blocks 1 which are sequentially fixedly connected by connecting plates 2 to form a combined drainage ditch. It can be quickly assembled and disassembled, and can be used repeatedly.

[0015] figure 1 and figure 2 It can be seen that three steps are set at one end of each U-shaped drain concrete unit block 1 to form an outer step area 4 , and three steps are set at the other end to form an inner step area 5 . Therefore, after two adjacent U-shaped drain concrete unit blocks 1 are butted, a docking reserve cavity 8 is formed between the outer step area 4 and the inner step area 5 .

[0016] Then the matching set in the docking reserved cavity 8 is equipped with an inflatable bag 9, the inflatable bag 9 contains an inflatable nozzle, and the port of the reserved cavity 8 is sealed and docked through the connecting p...

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, an outer layer compensation gap is set on the outside of the butt joint surfaces of two adjacent U-shaped drain concrete unit blocks 1, and an inner layer compensation gap is set on the inside.

Embodiment 3

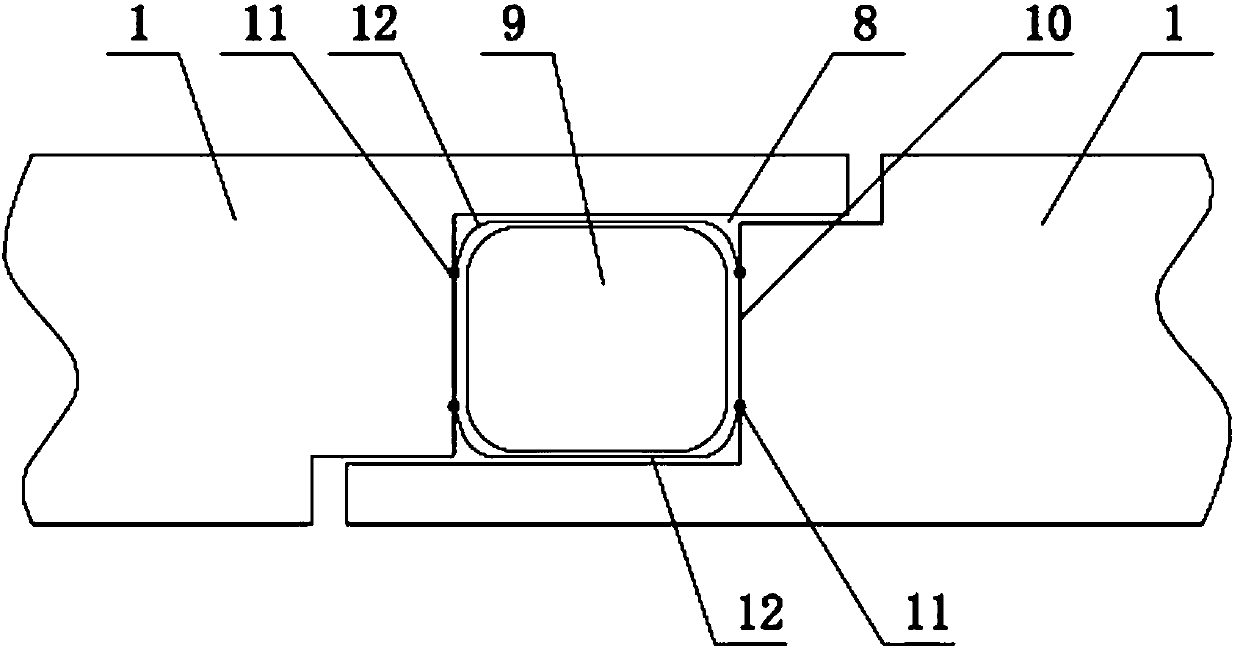

[0018] Embodiment 3: on the basis of embodiment 1, refer to image 3 , a pair of traction points are respectively arranged on the butt joint surfaces of two adjacent U-shaped drainage ditch concrete unit blocks at the inner end of the docking reserved cavity, and between the corresponding traction points between the adjacent two U-shaped drainage ditch concrete unit blocks Attached with leash. Setting traction points and traction belts on the butt joints of adjacent U-shaped drainage ditch concrete unit blocks can not only enhance the connection relationship, but more importantly, when two adjacent U-shaped drainage ditch concrete unit blocks move outward, through The traction belt clamps the airbag, forcing the airbag to deform, and further fits with the docking surface to prevent loose seams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com