Artificial colored sand and preparation method

A technology of artificial colored sand and quartz sand, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor mechanical strength, high cost, complicated preparation process, etc., achieve excellent aging resistance, low production heating temperature, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the above-mentioned artificial colored sand comprises the following steps: uniformly mixing acrylic resin, quartz sand, fumed silica, dispersant, defoamer, coupling agent and pigment, then sand grinding to a fineness of 20-40 μm, and then Add curing agent and solvent, mix thoroughly and evenly, then place the material in a drum, and stir at a constant temperature of 70-90°C for 15-30 minutes to obtain artificial colored sand.

[0044] Preferably, the rotation speed of the drum is 10-15 r / min.

Embodiment 1

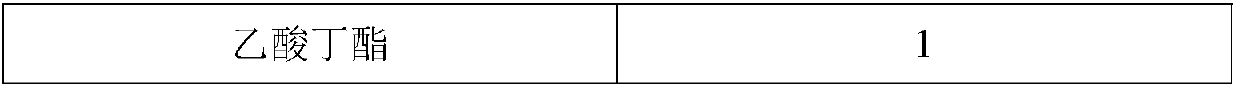

[0047] A kind of artificial colored sand, its raw material composition is shown in the following table:

[0048] Table 1 The raw material composition table of a kind of artificial colored sand

[0049] raw material

[0050] The preparation method of the above artificial colored sand comprises the following steps: mixing acrylic polyol resin, quartz sand, fumed silica, BYK-161, amphoteric surfactant, modified polysiloxane, isocyanate silane coupling agent and iron red pigment Mix the materials evenly, then sand them until the fineness is 20-40 μm, then add isophorone diisocyanate and butyl acetate, mix well, then put the mixed materials in the drum, adjust the speed to 10r / min, 90℃ Stir at constant temperature for 30 minutes to obtain artificial colored sand.

Embodiment 2

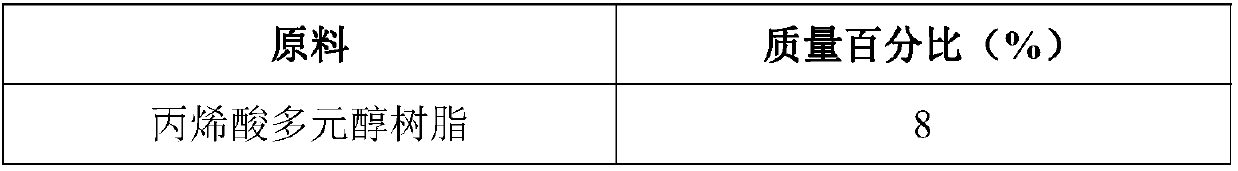

[0052] A kind of artificial colored sand, its raw material composition is shown in the following table:

[0053] Table 2 A raw material composition table of artificial colored sand

[0054] raw material

[0055] The preparation method of the above-mentioned artificial colored sand comprises the following steps: mixing acrylic polyol resin, quartz sand, fumed silica, BYK-161, triethoxysilane, modified polysiloxane, aminosilane and phthalocyanine blue pigment Evenly, then sand to a fineness of 20-40μm, then add hexamethylene diisocyanate and isomerized xylene, mix well, then put the mixture in the drum, adjust the speed to 10r / min, and keep the temperature at 70°C Stir for 30 minutes to obtain artificial colored sand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com