Glass fiber fabric reinforced polypropylene composite material as well as preparation method and application thereof

A composite material, glass fiber cloth technology, applied in artificial islands, infrastructure engineering, construction, etc., can solve the problems of inconvenient installation and dismantling, lack of constant temperature on the surface, heavy volume, etc., and achieve high efficiency, low cost, and total weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058]

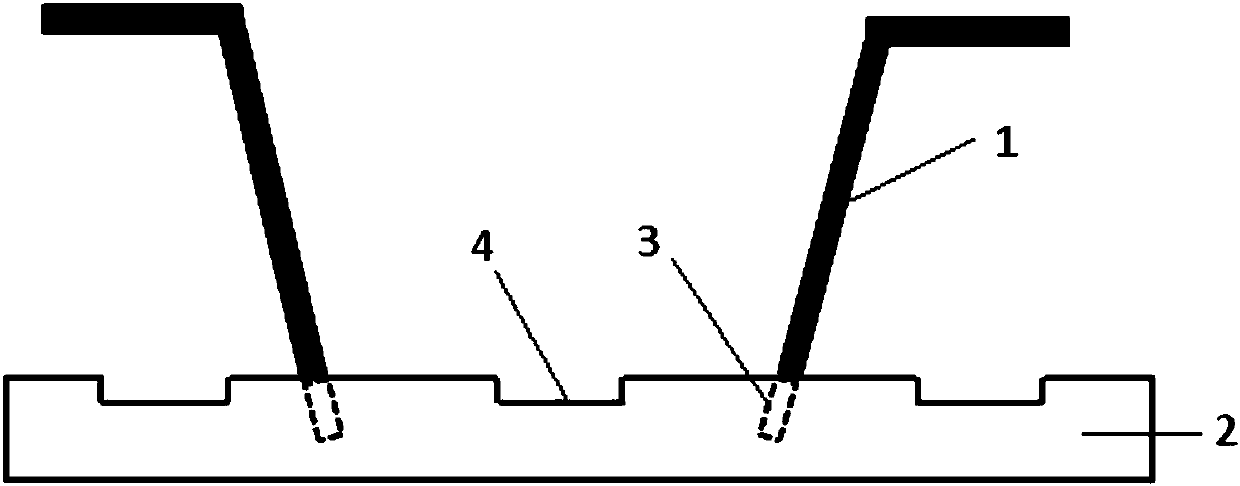

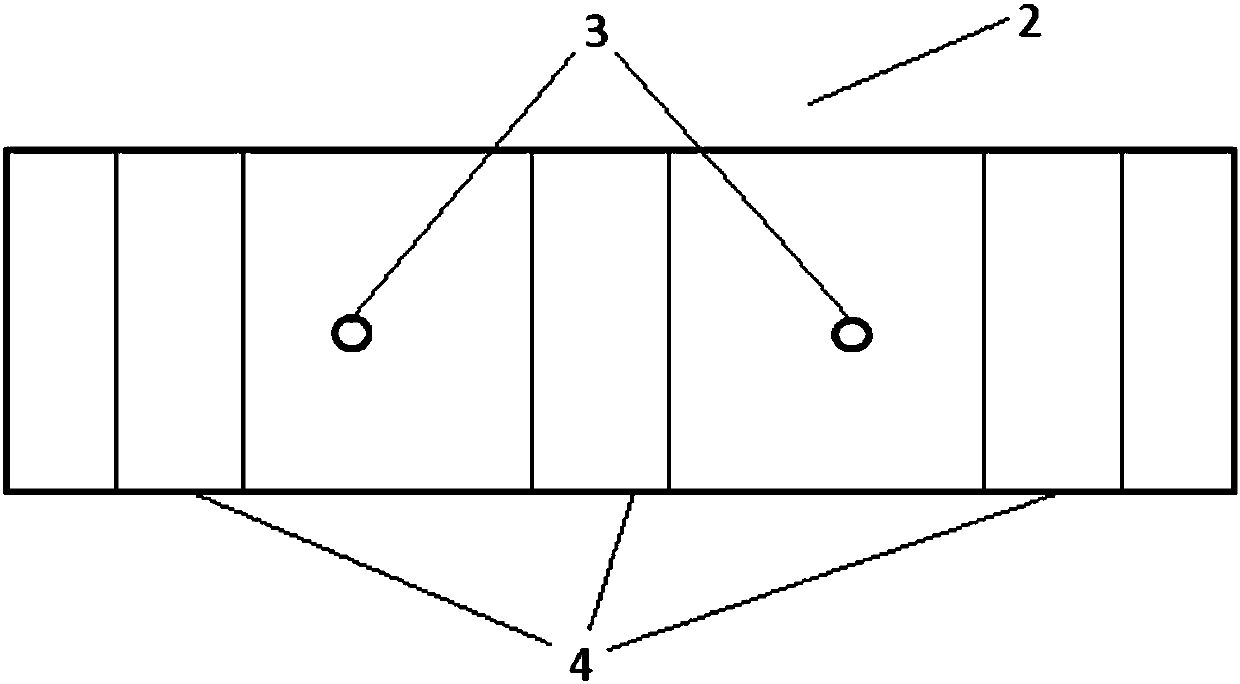

[0059] A kind of preparation method of glass fiber cloth reinforced polypropylene composite material, it comprises the steps:

[0060] (1) After mixing polypropylene, compatibilizer, light stabilizer and antioxidant, a mixture is obtained;

[0061] (2), the mixture is heated and melted, and the melted mixture is coated to obtain a polypropylene film;

[0062] (3), first preheating the glass fiber cloth, then pouring the polypropylene film onto the surface of the preheated glass fiber cloth, putting it into an oven for heating, and obtaining the glass fiber cloth drenched with the polypropylene film;

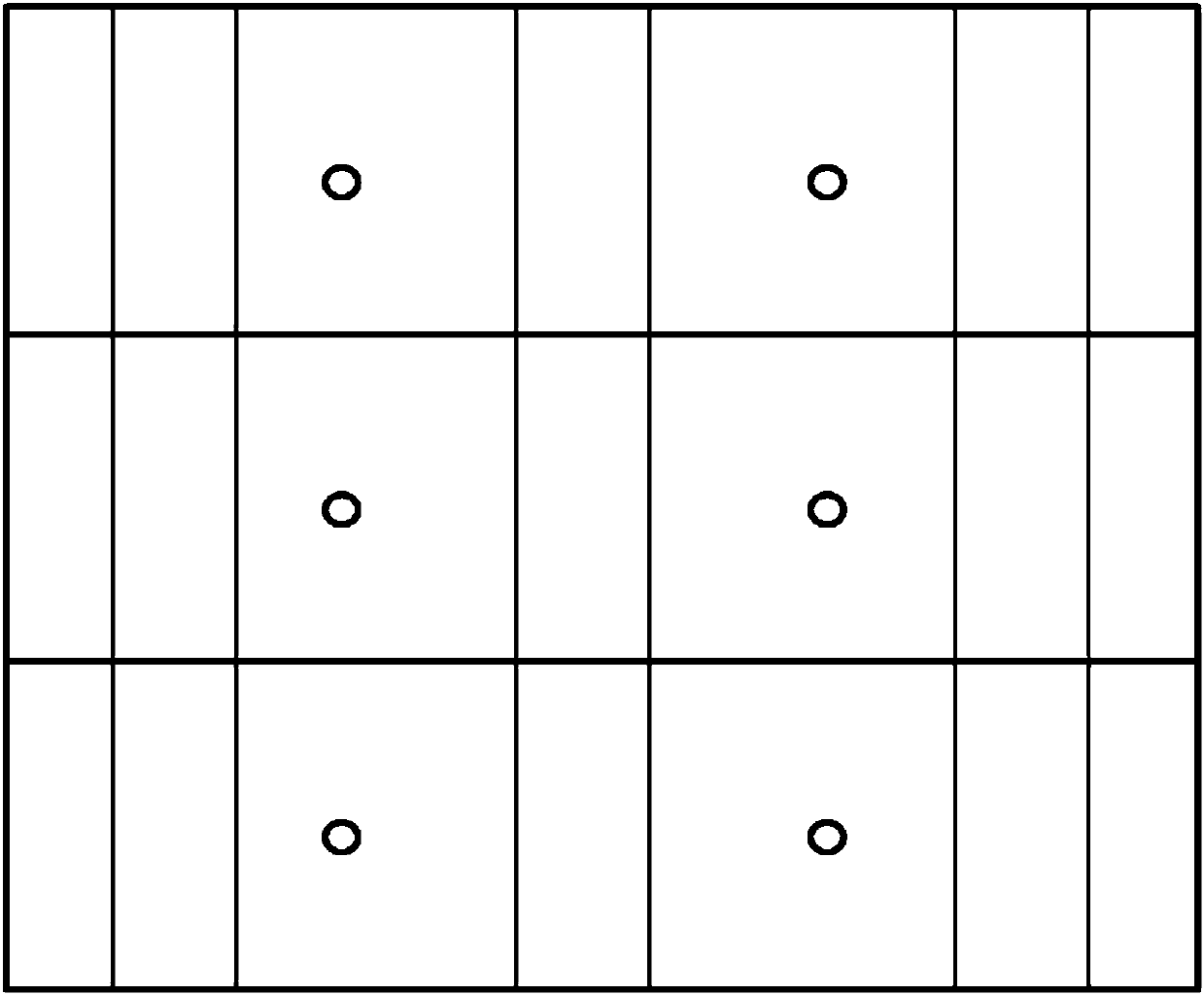

[0063] (4) Composite the glass fiber cloth that has been showered with polypropylene film to form a prepreg tape;

[0064] (5) After cutting the prepreg tapes, lay them up and perform hot pressing and cold pressing processes to obtain glass fiber cloth reinforced polypropylene composite materials.

[0065] Wherein, in step (2), the heating temperature may be 160-250°...

Embodiment 1

[0082]

[0083] Fiberglass cloth reinforced polypropylene composite material in the present embodiment, it comprises:

[0084]

[0085] Among them, the glass fiber cloth is within 40-60 parts, the gram weight is within 140-300g / ㎡, the polypropylene is within 30-50 parts, the compatibilizer is within 6-9 parts, and the light stabilizer is within 0.8 Within ‐1 part, antioxidants within 0.3‐0.6 parts are all possible.

[0086] The weight of glass fiber cloth is 200g / ㎡.

[0087] The compatibilizer is polypropylene grafted maleic anhydride.

[0088] The light stabilizer is o-hydroxybenzophenone.

[0089] The antioxidant is tris[2,4-di-tert-butylphenyl]phosphite and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester by weight percentage It is a mixture composed of 1:1‐2:1, wherein the weight percentage of tris[2,4-di-tert-butylphenyl]phosphite is 0.2wt%, tetrakis[β-(3,5-di-tert-butyl The percentage by weight of -4-hydroxyphenyl) propionate] penta...

Embodiment 2

[0111]

[0112] Fiberglass cloth reinforced polypropylene composite material in the present embodiment, it comprises:

[0113]

[0114] Among them, the weight of glass fiber cloth is 140g / ㎡.

[0115] The compatibilizer is γ-aminopropyltriethoxysilane.

[0116] The light stabilizer is o-hydroxybenzophenone.

[0117] The antioxidant is tris[2,4-di-tert-butylphenyl]phosphite and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester by weight percentage It is a mixture composed of 1:1‐2:1, wherein the weight percentage of tris[2,4-di-tert-butylphenyl]phosphite is 0.2wt%, tetrakis[β-(3,5-di-tert-butyl The percentage by weight of -4-hydroxyphenyl) propionate] pentaerythritol ester is 0.4 wt%.

[0118]

[0119] The preparation method of glass fiber cloth reinforced polypropylene composite material in the present embodiment, it comprises the steps:

[0120] (1), after mixing polypropylene, compatibilizer, light stabilizer and antioxidant, put it int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com