Temperature-sensitive and salt-sensitive copolymer gel and preparation method thereof

A technology of copolymer and gel, which is applied in the field of temperature-sensitive and salt-sensitive copolymer gel water shutoff agent and its preparation, which can solve the problem of high-temperature and high-salt oil reservoir plugging, poor temperature and salt resistance of water shutoff agent, and easy flocculation and other problems, to achieve good temperature sensitivity and salt resistance, less damage to the formation, and a simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

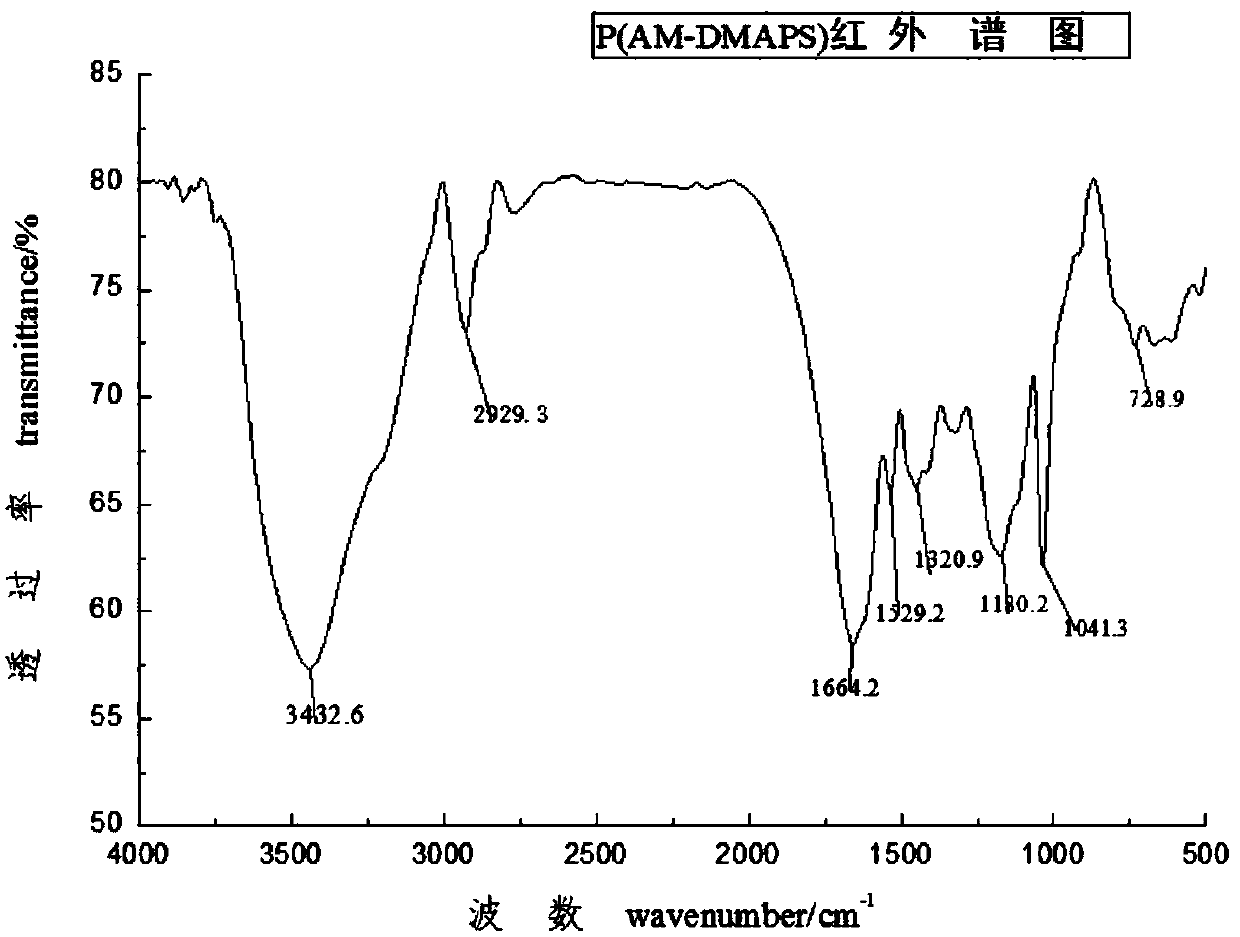

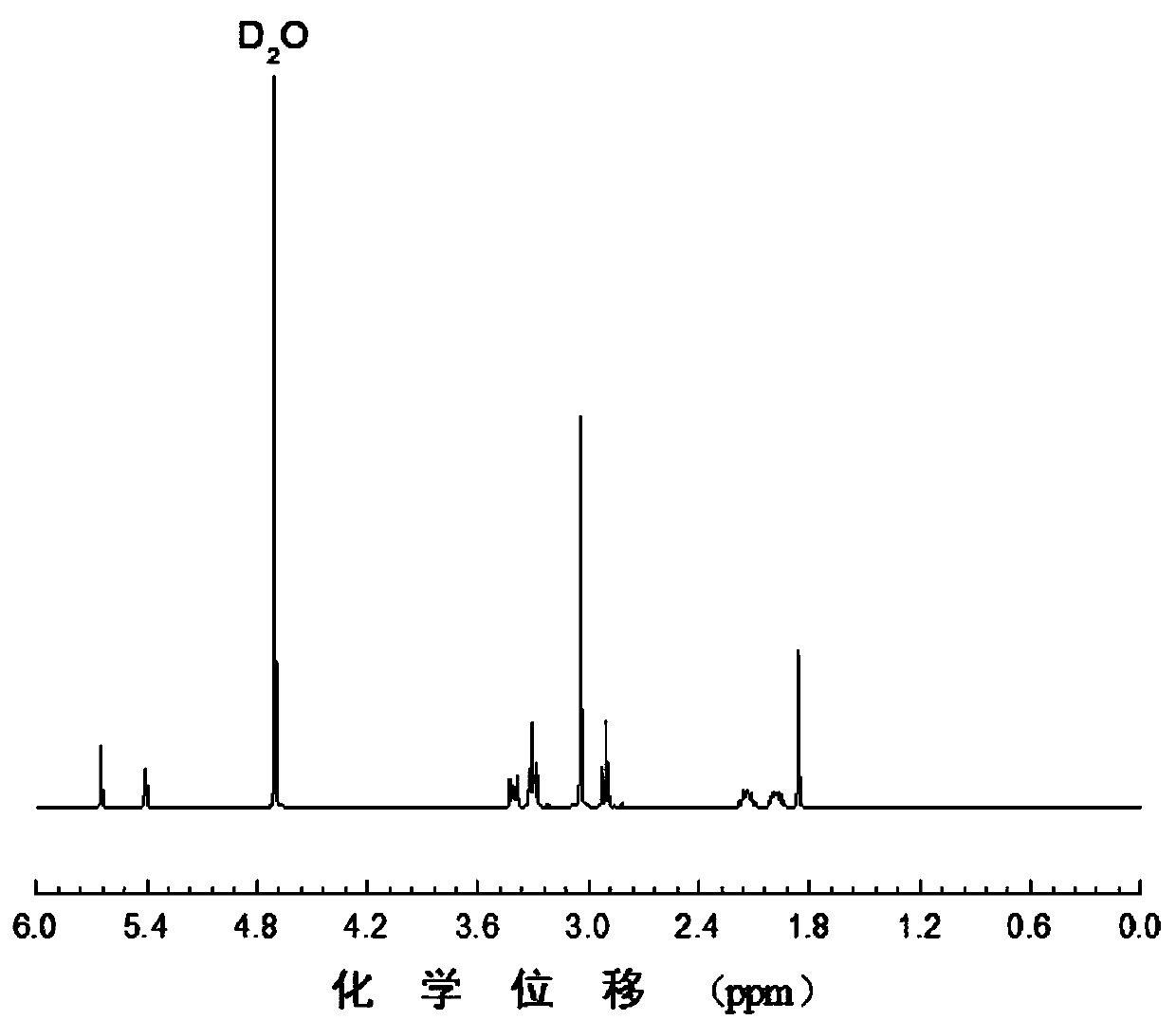

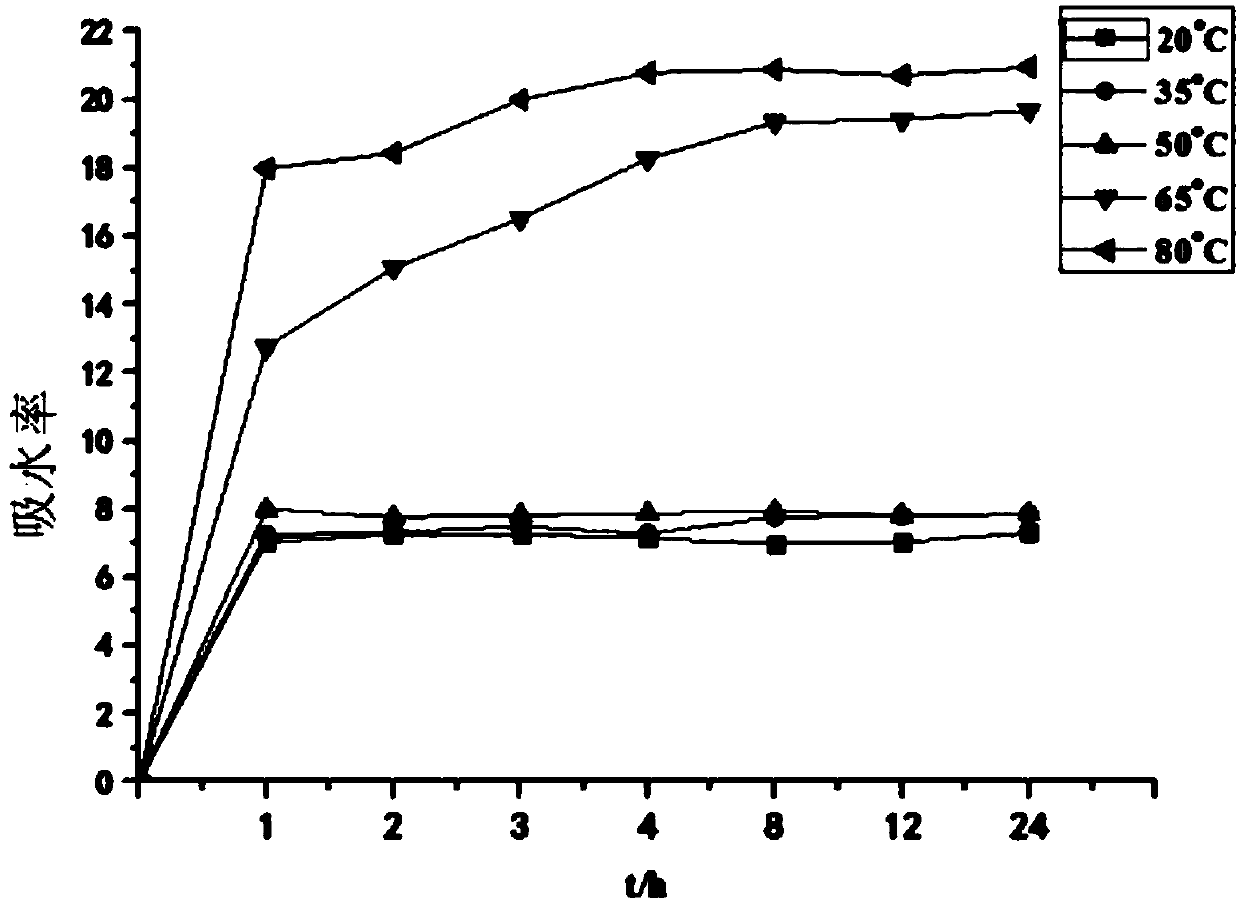

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a temperature-sensitive salt-sensitive copolymer gel, comprising the following steps:

[0041] (1) Preparation of sulfobetaine monomer SPP: Dissolve 3.2ml of dimethylaminopropyl methacrylamide (DMAPMA) in 20mL of ether, then add 2.15g of 1,3-propane sultone (PS) , the solution was left to stand at room temperature for 16 to 24 hours; the white precipitate obtained after the standstill was collected by filtration, washed three times with acetone, and then dried in vacuum; through two experiments, the target product [3-(methylpropene) was obtained. Amido)propyl]dimethyl(3-thiopropyl)ammonium hydroxide inner salt (SPP).

[0042] (2) Add 36g of starch into a 500ml one-necked flask, and add 360ml of water, and gelatinize in a constant temperature water bath at 75°C under mechanical stirring until it becomes completely transparent.

[0043](3) Add 18g of functional monomer SPP and 18g of acrylamide (AM) to the gelatinized starch to obtain the first rea...

Embodiment 2

[0046] A method for preparing a temperature-sensitive salt-sensitive copolymer gel, comprising the following steps:

[0047] (1) Preparation of sulfobetaine monomer DMAPS: Add 17.27g methacryloxyethyl dimethylamine (DM) and 34.54g acetone and 0.02947g inhibitor (p-hydroxyanisole) into 250ml three ports In the flask; dropwise add the mixed solution of 12.2g 1,3-propyl sultone (PS) and 12.2g acetone, the dropwise addition is completed within 2 hours, and reflux reaction at 55°C for 20 hours. After the reaction is completed, there is A large number of white crystals were precipitated and filtered; the filter cake was repeatedly washed with a large amount of acetone and ether mixture, and dried in vacuum at 65°C until the mass was constant to obtain monomer DMAPS.

[0048] (2) Add 24g of starch into a 500ml one-necked flask, and add 360ml of water, and gelatinize in a constant temperature water bath at 75°C under mechanical stirring until it becomes completely transparent.

[004...

Embodiment 3

[0052] A method for preparing a temperature-sensitive salt-sensitive copolymer gel, comprising the following steps:

[0053] (1) Add 24g of starch into a 500ml one-necked flask, and add 360ml of water, and gelatinize in a constant temperature water bath at 75°C under mechanical stirring until it becomes completely transparent.

[0054] (2) Add 12g functional monomer octadecylethoxy sulfobetaine and 12g acrylamide (AM) to the gelatinized starch to obtain the first reaction solution; then add 0.24g Stir the cross-linking agent N,N-methylenebisacrylamide and 0.12 g of the initiator ammonium persulfate evenly, seal the reaction container with a plastic wrap, and put it in a 60°C oven for 24-36 hours to obtain a crude gel.

[0055] (3) The coarse gel is cut into small pieces with scissors, then soaked in pure water and stirred for 12 hours, and the water is changed at 1 hour, 2 hours, 4 hours, 6 hours, and 12 hours, so that the unreacted polymer gel can be removed. monomers and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com