Cervical vertebra back way door opening plate machining process

A processing technology and door panel technology, which is applied in the field of medical devices, can solve problems such as internal tissue damage and tissue damage risks, and achieve the effects of reducing the unqualified rate, improving the company's benefits, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

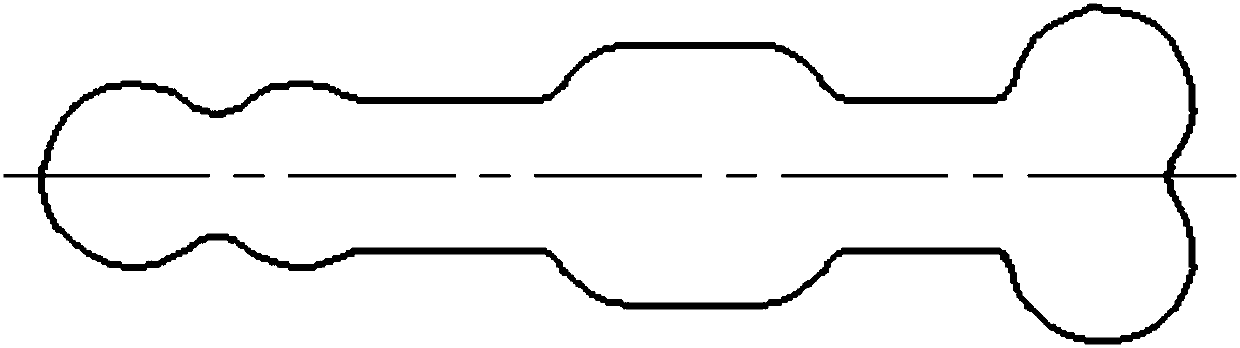

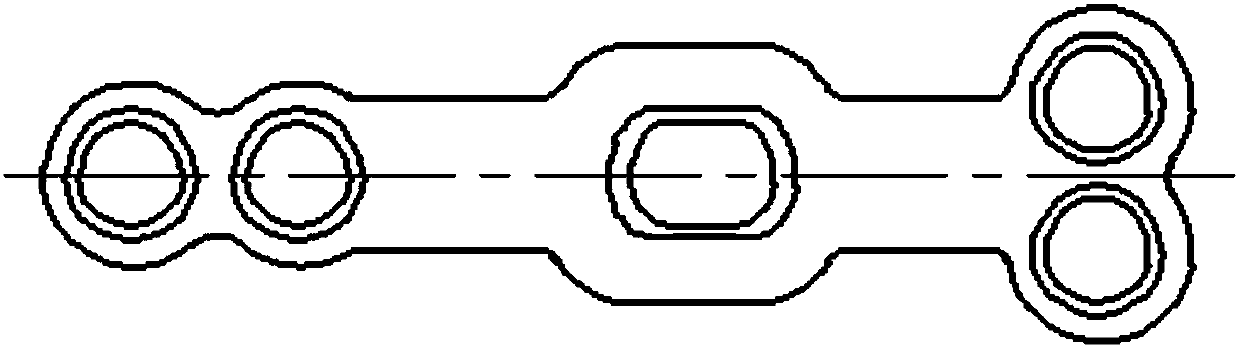

[0037] Such as Figure 4 with Figure 5 As shown, a process for processing the posterior cervical door opening plate of the present invention, prepares materials:

[0038] Titanium rods with a diameter of φ16~φ20 are selected for the blank, and the length is between 2 meters and 3 meters, where the mass percentage of Ti is ≥98.71%. The length of the titanium rod is much longer than the length of the door opening plate, because the titanium rod protrudes during product processing. The part is shorter, and the product processing rigidity is better guaranteed;

[0039] In this embodiment, the blank is a rod (φ16~φ20)×(2000-3000) / (80-100), that is, the diameter of the polished rod is 16mm-20mm, and the length is 2-3 meters. A total of 80-100 pieces of finished door opening panels are produced ;

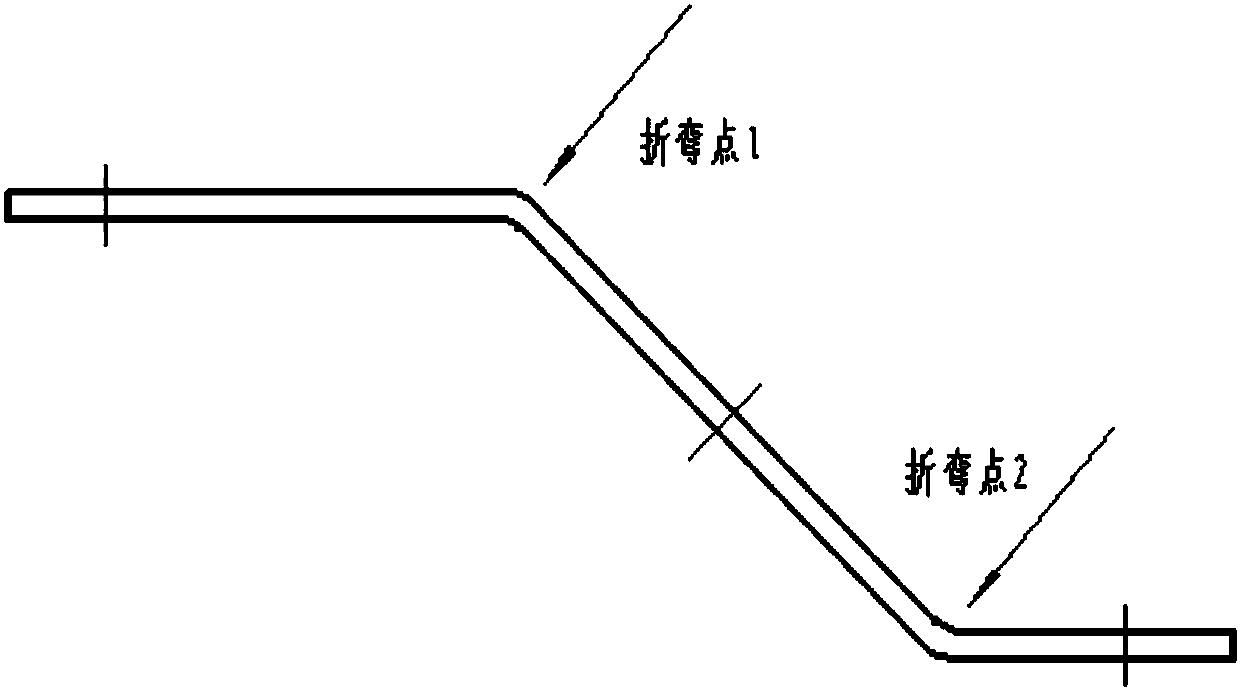

[0040] Turning center: the blank titanium rod is clamped by a jacket with a diameter matching the titanium rod, and fixed on the turning center, and then the blank is divided into three sectio...

Embodiment 2

[0068] The difference between this embodiment and the first embodiment lies in the different selected parameters. Such as Figure 4 with Figure 5 As shown, a process for processing a posterior cervical door opening plate of the present invention. Material preparation: a titanium rod with a diameter of φ16~φ20 is selected as the blank, and the length is between 2 meters and 3 meters, where the mass percentage of Ti is ≥98.71%. The length of the rod is much longer than the length of the door opening plate. Due to the short extension of the titanium rod during product processing, the rigidity of the product is better guaranteed;

[0069] In this embodiment, the blank is a polished rod φ16×3000 / 100, that is, the polished rod has a diameter of 16mm and a length of 3 meters, and a total of 100 pieces are produced;

[0070] Turning center: Use a jacket with a diameter of φ16.2 to clamp the blank titanium rod and fix it on the turning center, and then divide the blank into three sections...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com