Adhesive promoters and methods for use on polar textile to bond non-polar substrates

A technology of composition and solvent composition, applied in the direction of adhesive types, chemical instruments and methods, grafted polymer adhesives, etc., can solve the problems of no adhesion, achieve easy flexibility, and improve processability , Balance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

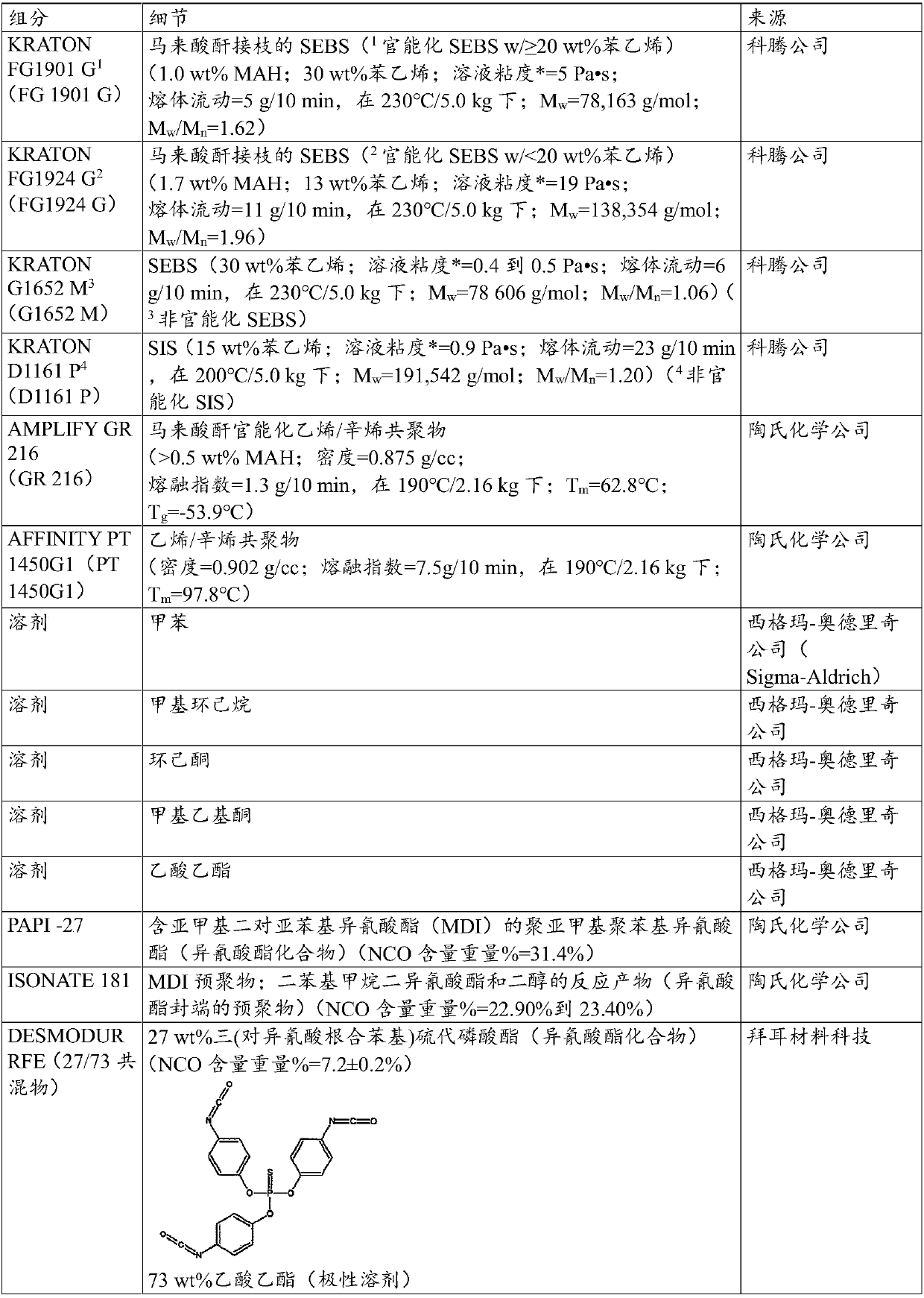

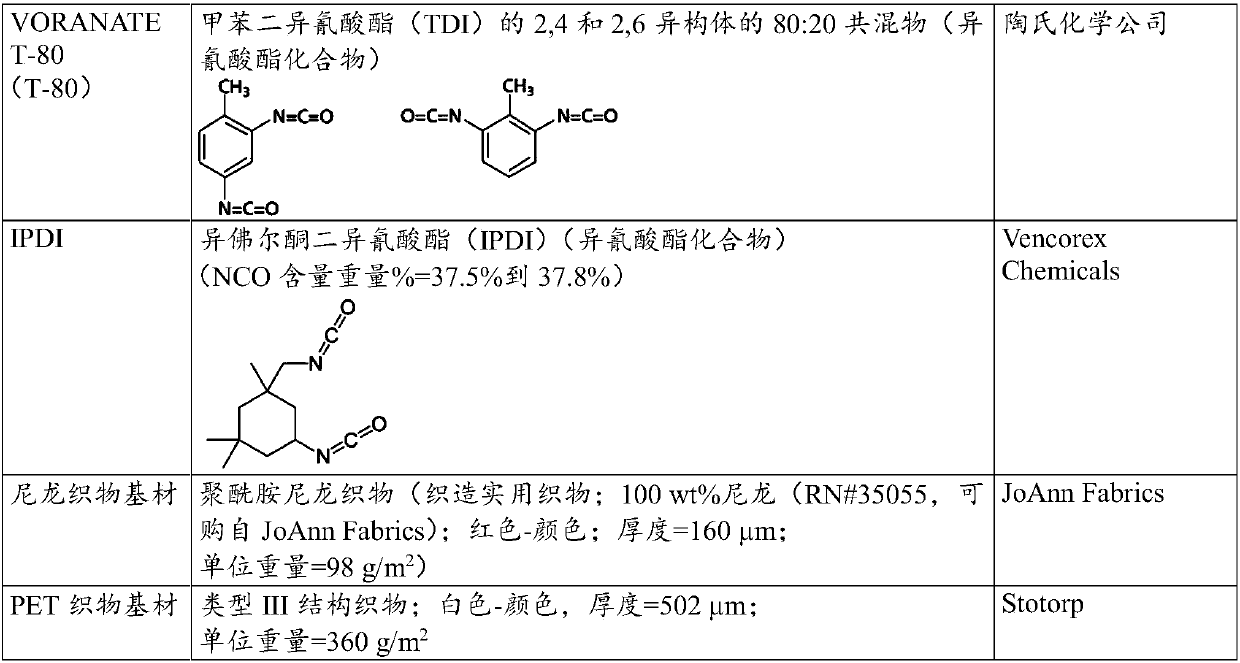

[0224] Examples of the present disclosure are provided by way of illustration and not limitation. A summary of materials used in the following examples is provided in Table 1.

[0225] Table 1: Materials

[0226]

[0227]

[0228] *Solution viscosity - 25 wt% polymer in toluene at 25°C (Pa·s)

[0229] ** Melt index can be calculated according to the following formula (see USP6,335,410): I 2 (190°C / 2.16kg) = 3.6126[10 (log(η)-6.6928) / -1.1363 ] - 9.31851, where η = melt viscosity in cP at 350°F (177°C). Melt viscosity = 13,000 cP at 177°C.

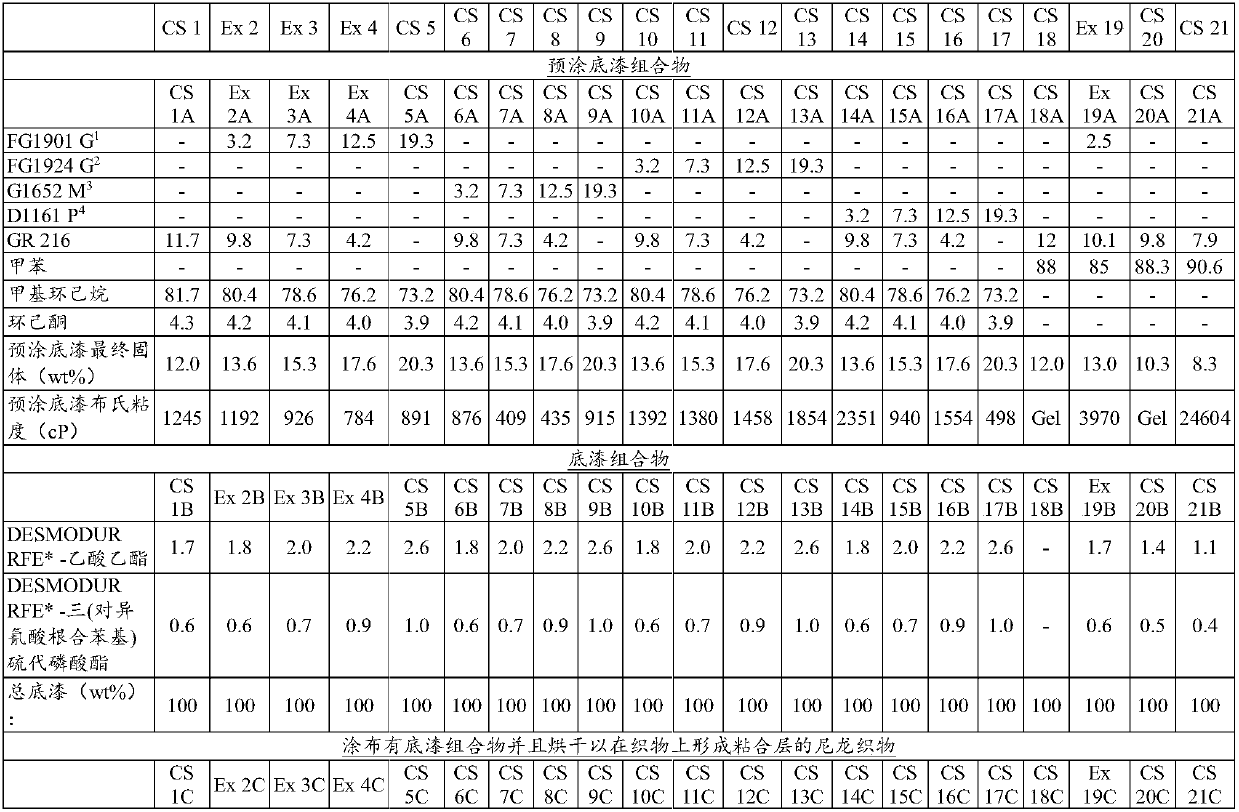

[0230] 1. Preparation of Primer Composition

[0231] A. Preparation of Precoat Primer Compositions

[0232] The precoat primer compositions were prepared using three separate methods.

[0233] Cold blending (solution blending at room temperature (22°C)): Weigh a given amount of solvent into two 2 L three-neck round bottom glass flasks in a fume hood. After attaching a reflux condenser and an overhead mechanical stirrer, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com