Method for determining filling index of coarse granular material and realizing on-site quality control

A technology of coarse-grained material and granular quality, applied in the direction of self-adaptive control, general control system, control/regulation system, etc., can solve the problems of incomplete theory and restricting the development of modern high dams, and achieve the effect of ensuring the safety of construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

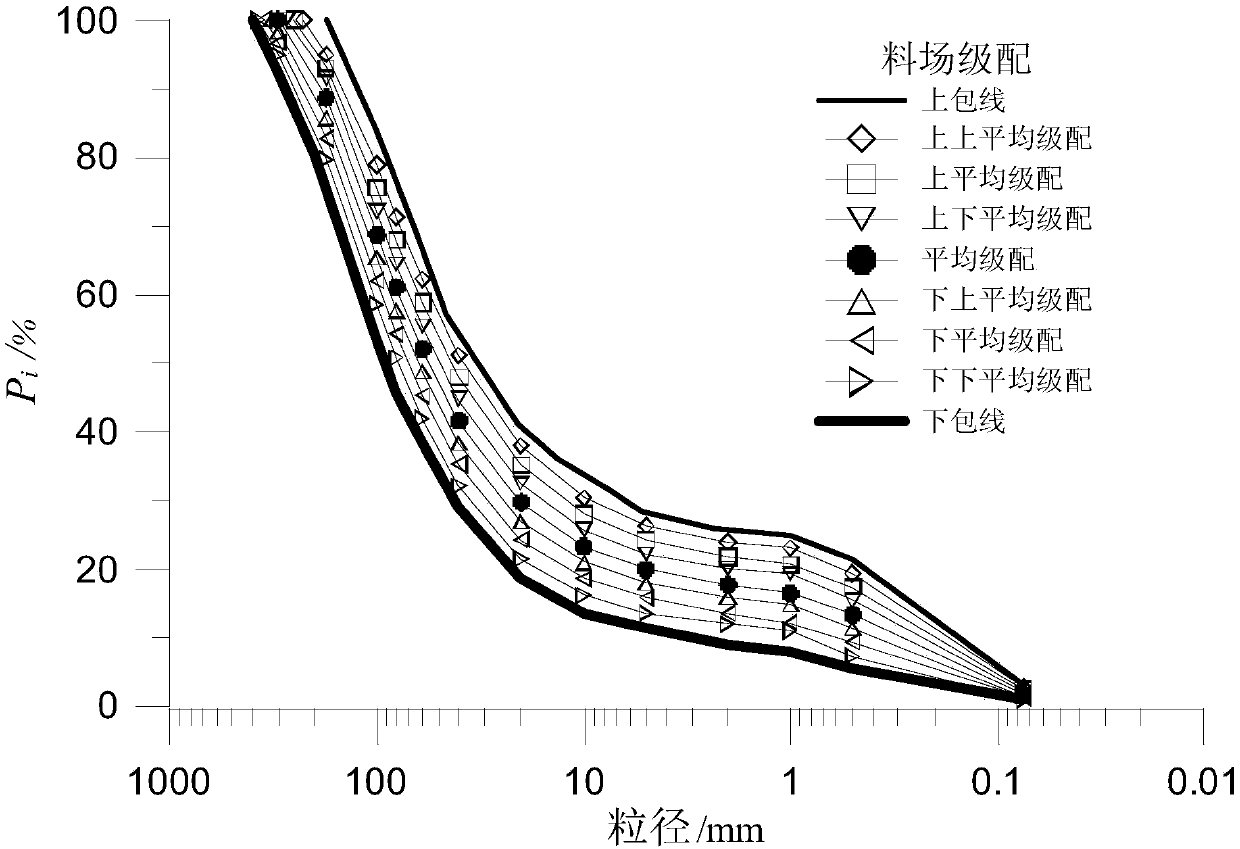

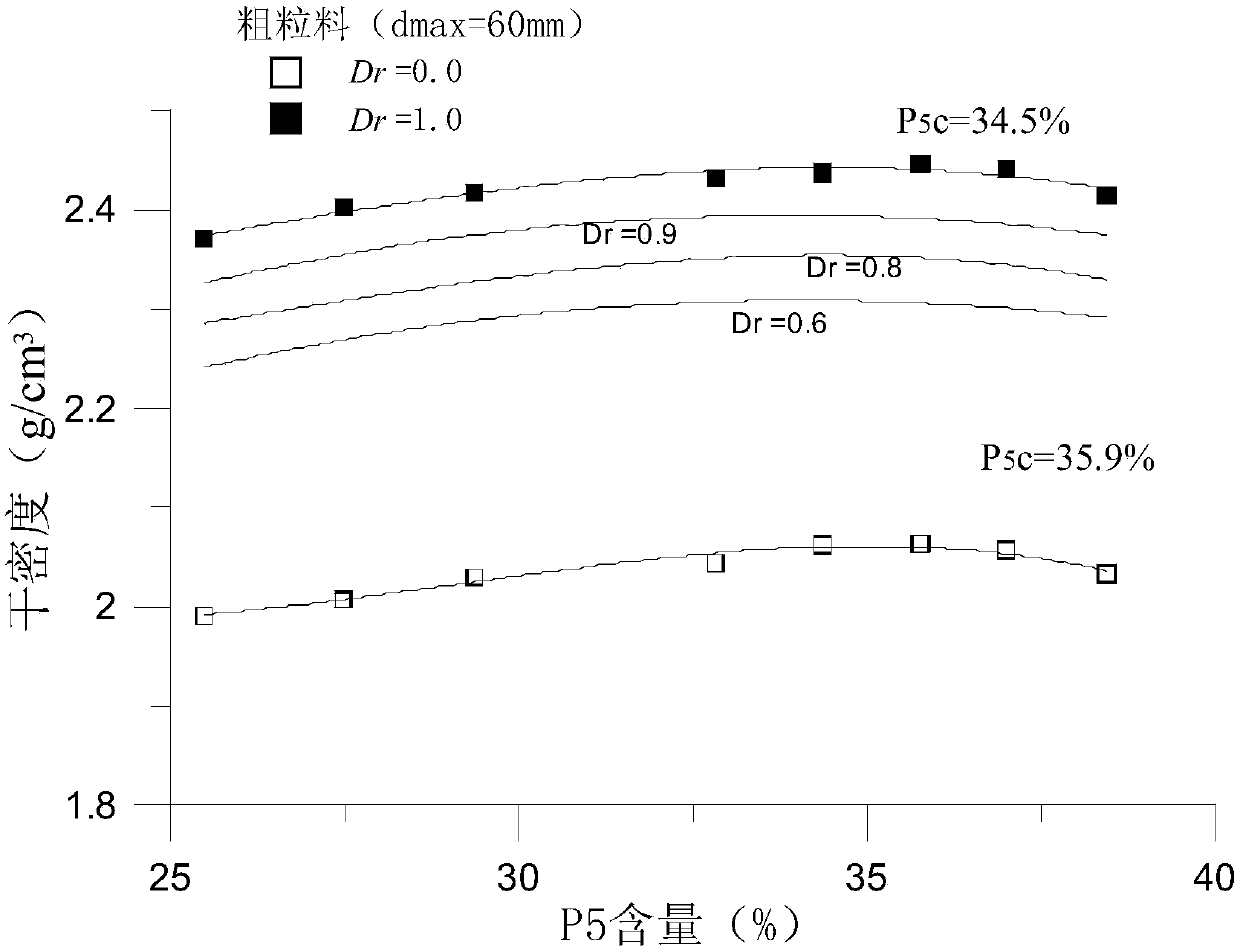

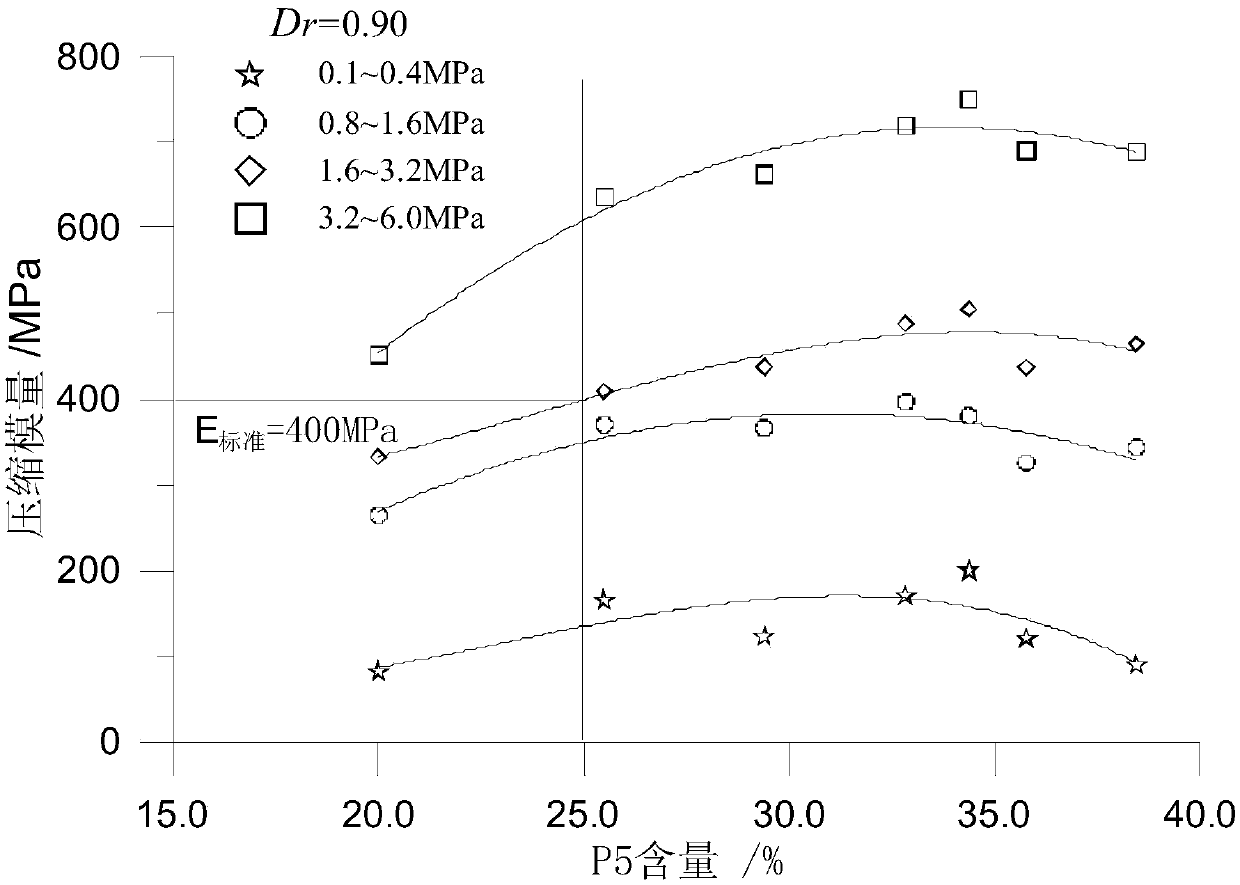

[0067] In this implementation case, the relative density test and compression test are carried out in combination with the gradation of the stockyard and the scale gradation of the coarse-grained material for dam construction in a certain project. According to the method suggested by this patent, the dual-control index of the porosity and relative density of the coarse-grained material is determined. . The project dam is located in a strong earthquake area, and the design index of relative density of filling coarse aggregate is 0.9. figure 1 There are 98 groups in total, and the maximum particle size is 175mm-400mm.

[0068] Step 1. Statistically analyze the particle mass distribution of 98 groups of coarse-grained material gradations in the stockyard, and put forward the distribution formula shown in formula (2) for inspection. The average correlation coefficient is greater than 0.98, which can better reflect the coarse-grained material gradation. Particle distribution prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com