Heaping and drainage method combining fine particle tailing dry heaping damming and wetting

A technology for fine-grained tailings and tailings accumulation dam, applied in chemical instruments and methods, dams, buildings, etc., can solve the problems of low tailings bottom flow concentration, low accumulation dam strength, complicated operation, etc., and achieve the overall cost of construction. Low, lower transportation cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method of fine-grained tailings dry stacking dam combined with wet drainage according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

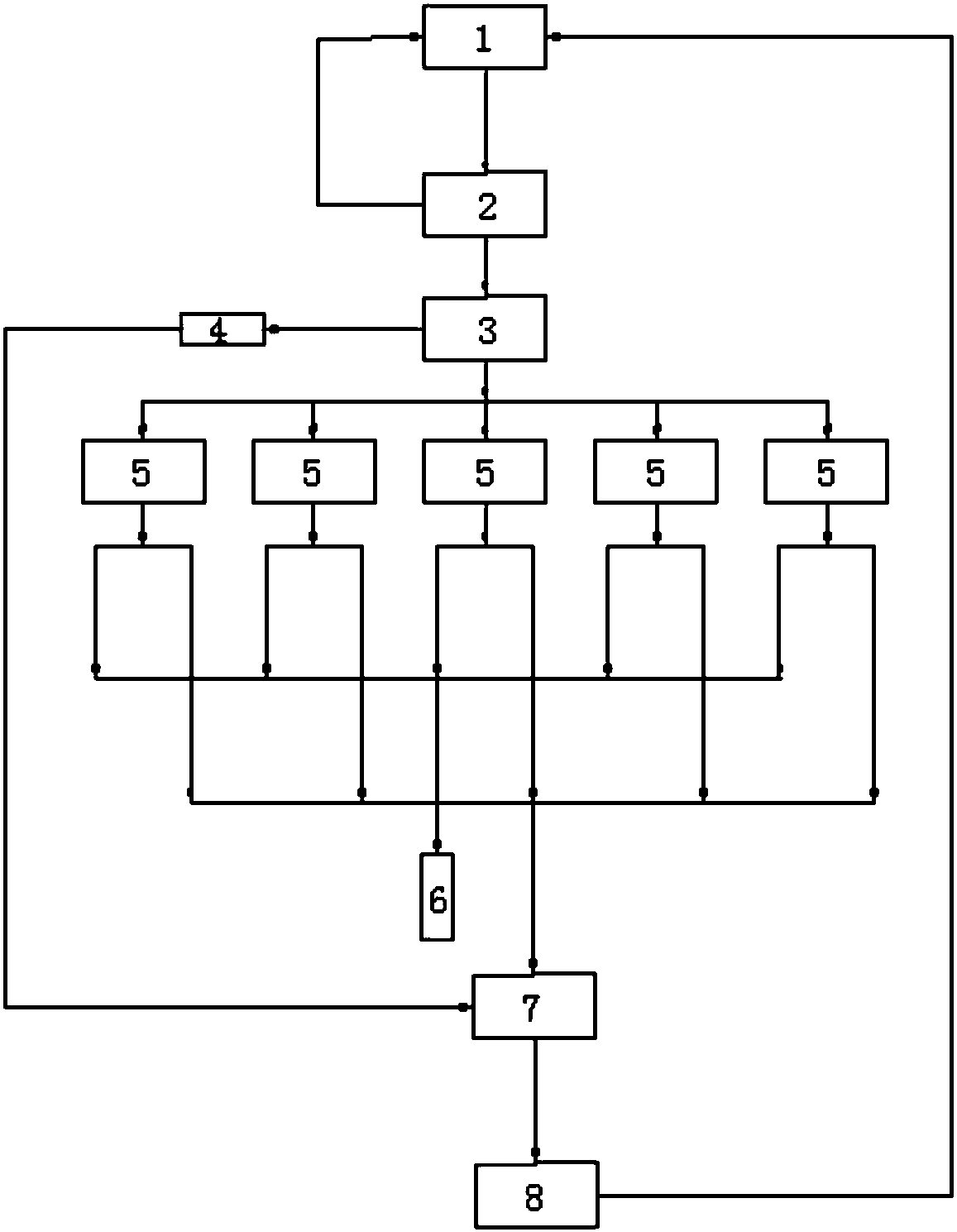

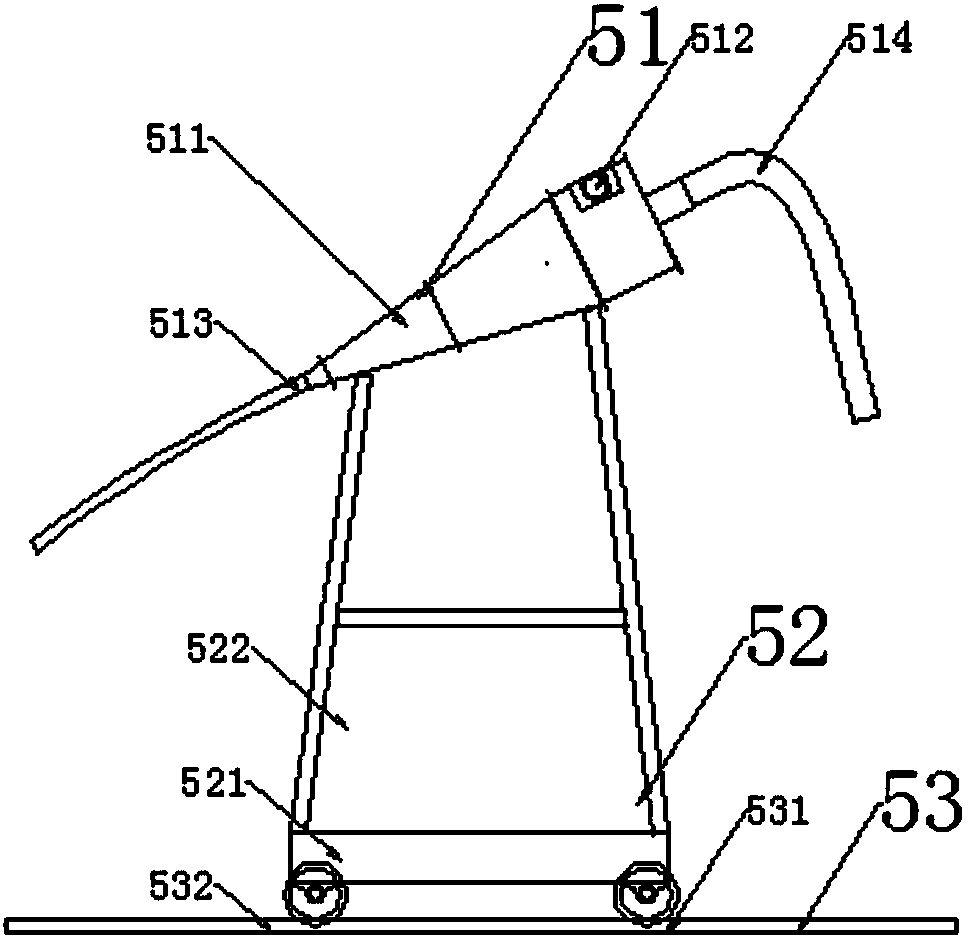

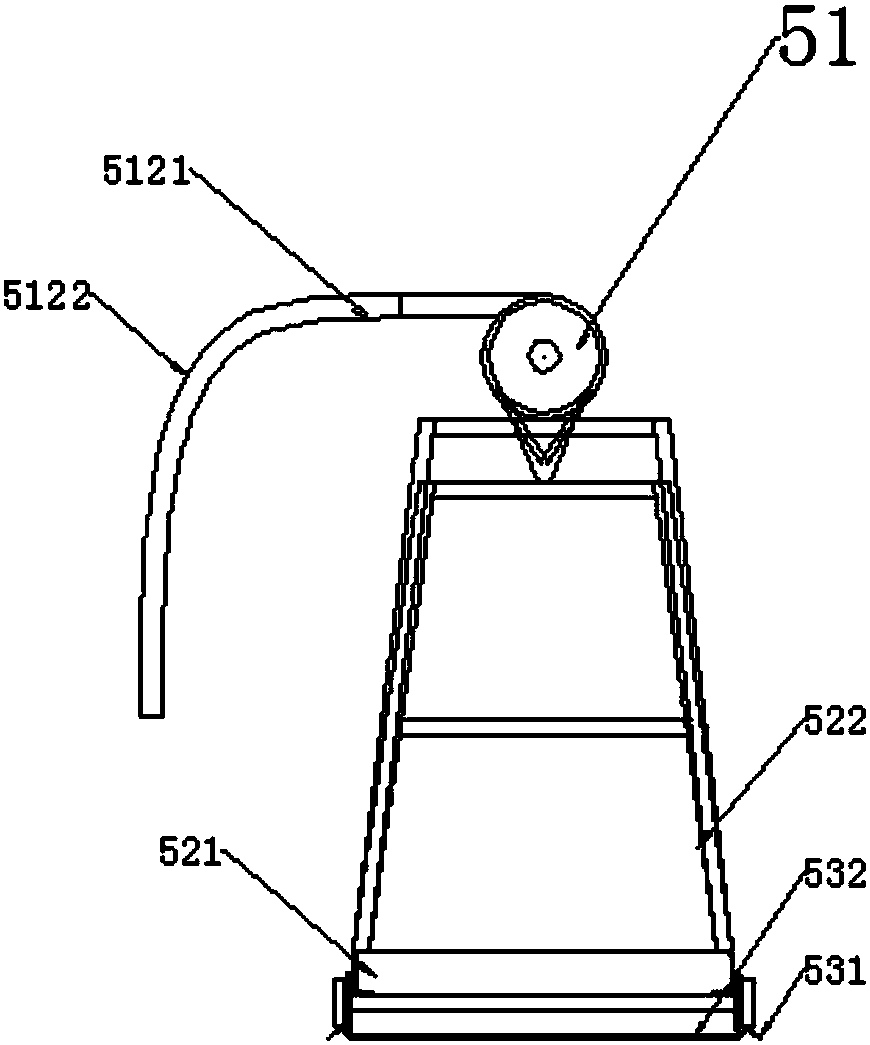

[0028] Such as Figure 1-4As shown, the present invention combines a fine-grained tailings dry stacking dam with a wet stacking method, which includes a concentrator 1, a thickener 2, a tailings conveying pipe 3, a diverting slurry discharge pipe 4, and a mobile separation Machine 5, tailings accumulation dam 6, tailings pond 7 and downstream reservoir 8, the mobile separator 5 includes a hydraulic separator 51, a movable support 52 and a walking guide rail 53, and the hydraulic separator 51 includes a hydraulic Cyclone 511, tailings slurry inlet pipe 512, underflow output pipe 513 and overflow drain pipe [514], the movable support 52 includes a walking mechanism 521 and a placement frame 522, and the tailings slurry inlet pipe 512 includes a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com