Metal fire melted mark quantitative metallography and phase analysis system and method

A quantitative metallographic and physical phase analysis technology, applied in material analysis, material analysis, image analysis, etc. using radiation diffraction, to achieve the effect of being proactive, increasing reliability, improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Those skilled in the art should know that identifying the grain number, size and other dimensional information of the metallographic structure of the melt mark through image processing can not only make the image analysis process simpler and faster, avoid subjective errors caused by manual evaluation, but also It can quantitatively carry out serialized, systematic and standardized research on fire traces, and promote the improvement of the identification level of melt marks. Therefore, this example takes typical metal fire melt marks as the research object, and based on digital image processing technology, various results are obtained. The average grain diameter, the number of grains, and the grain size level of the melt marks were used to establish a method that can quantitatively analyze and identify the melt marks. The determination of the cause and responsibility has laid an important foundation.

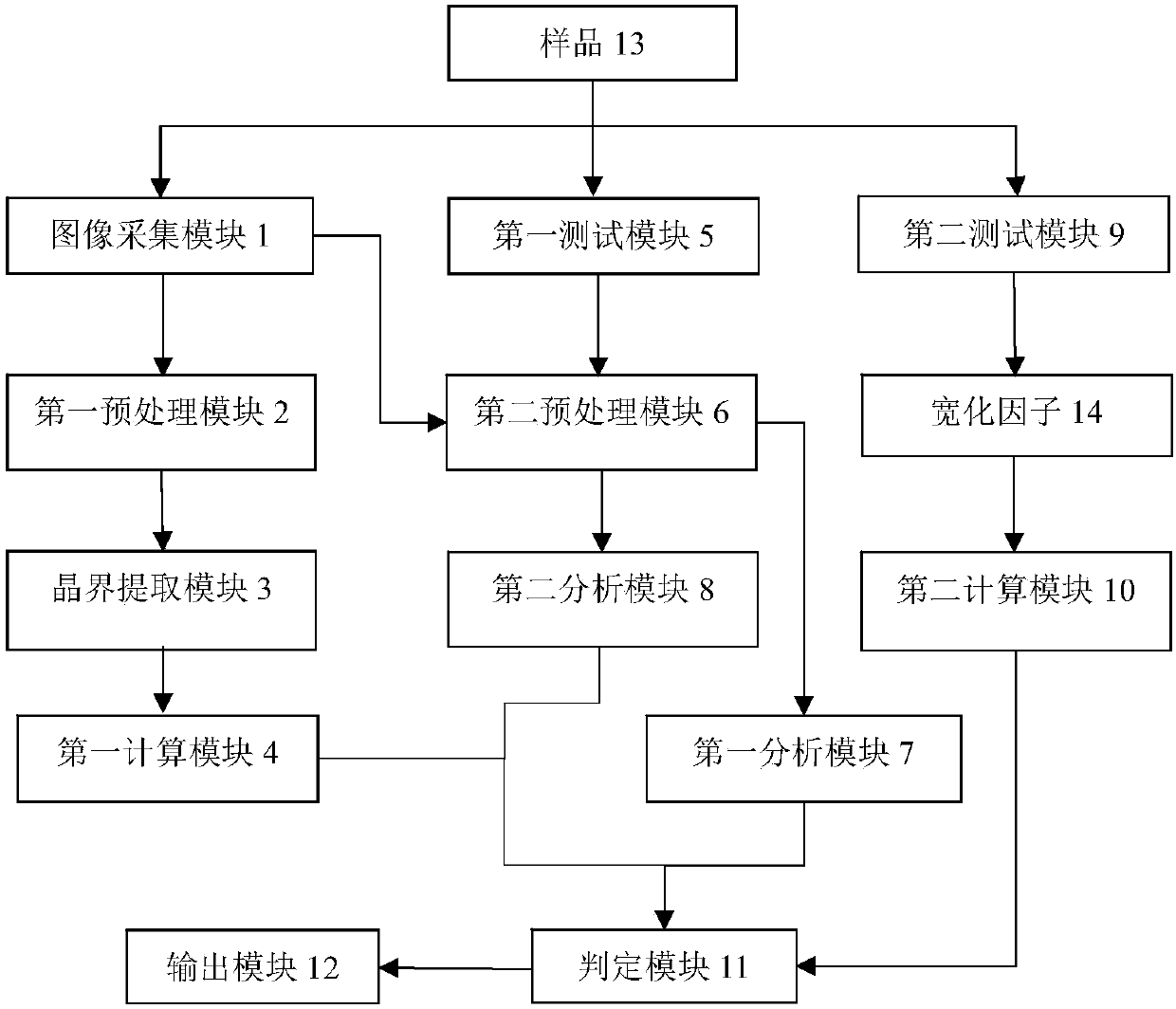

[0056] Such as figure 1 As shown, this embodiment provides a quanti...

Embodiment 2

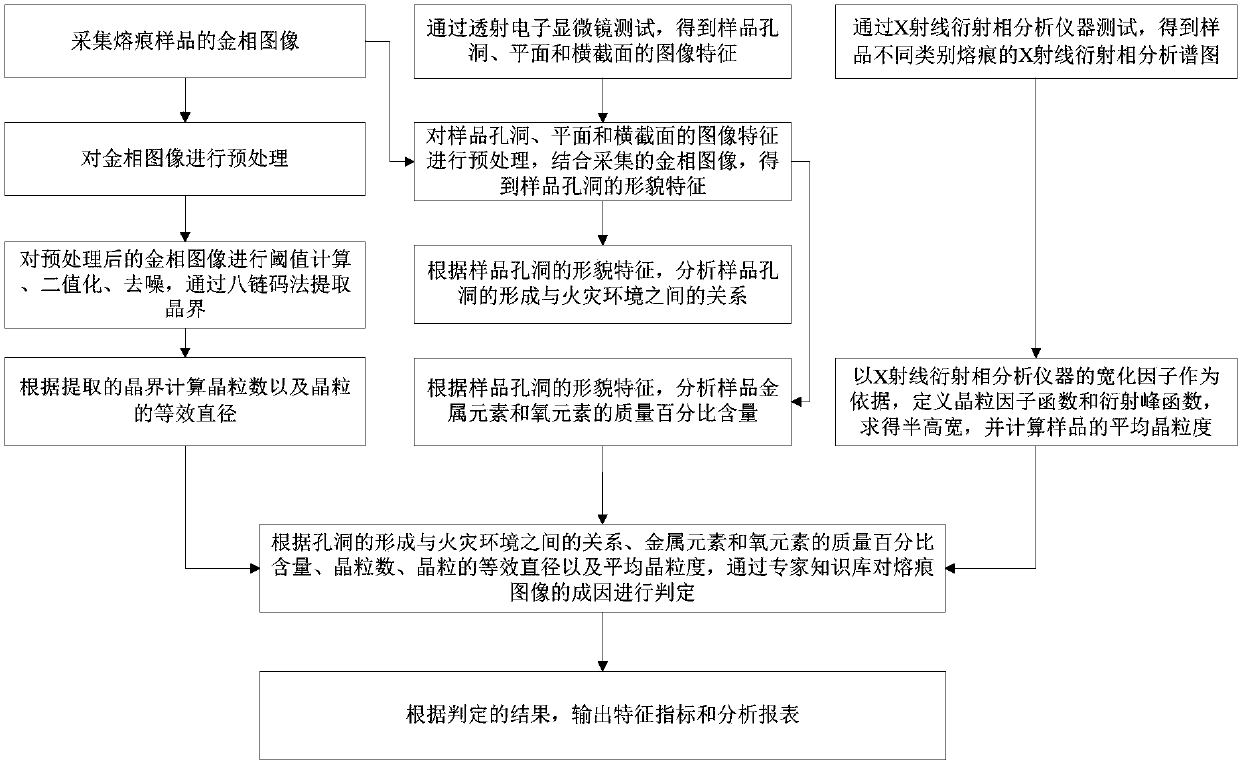

[0075] Such as figure 2 As shown, the present embodiment provides a method for quantitative metallographic and physical phase analysis of metal fire melt marks, the method comprising the following steps:

[0076] S101, collecting metallographic images of the melt sample;

[0077] S102. Preprocessing the metallographic image;

[0078] S103. Perform threshold calculation, binarization, and denoising on the preprocessed metallographic image, and extract grain boundaries through the eight-chain code method;

[0079] S104. Calculate the number of grains according to the extracted grain boundaries, and use the maximum and minimum values of all connected regions in the X-axis and Y-axis directions as the equivalent diameter of the grains;

[0080] S105. Obtain image features of sample holes, planes and cross-sections through a transmission electron microscope test;

[0081] S106. Preprocessing the image features of the sample holes, planes and cross sections, and combining the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com