Construction method of cast-in-situ concrete-supported prefabricated connecting beam in strip foundation pit

A construction method and connecting beam technology, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as the inability to realize the repeated use of connecting beams, increase the workload of later chiseling, and the complex force of concrete supports, etc., to achieve The effect of strengthening the restraint, simplifying the stress state, and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

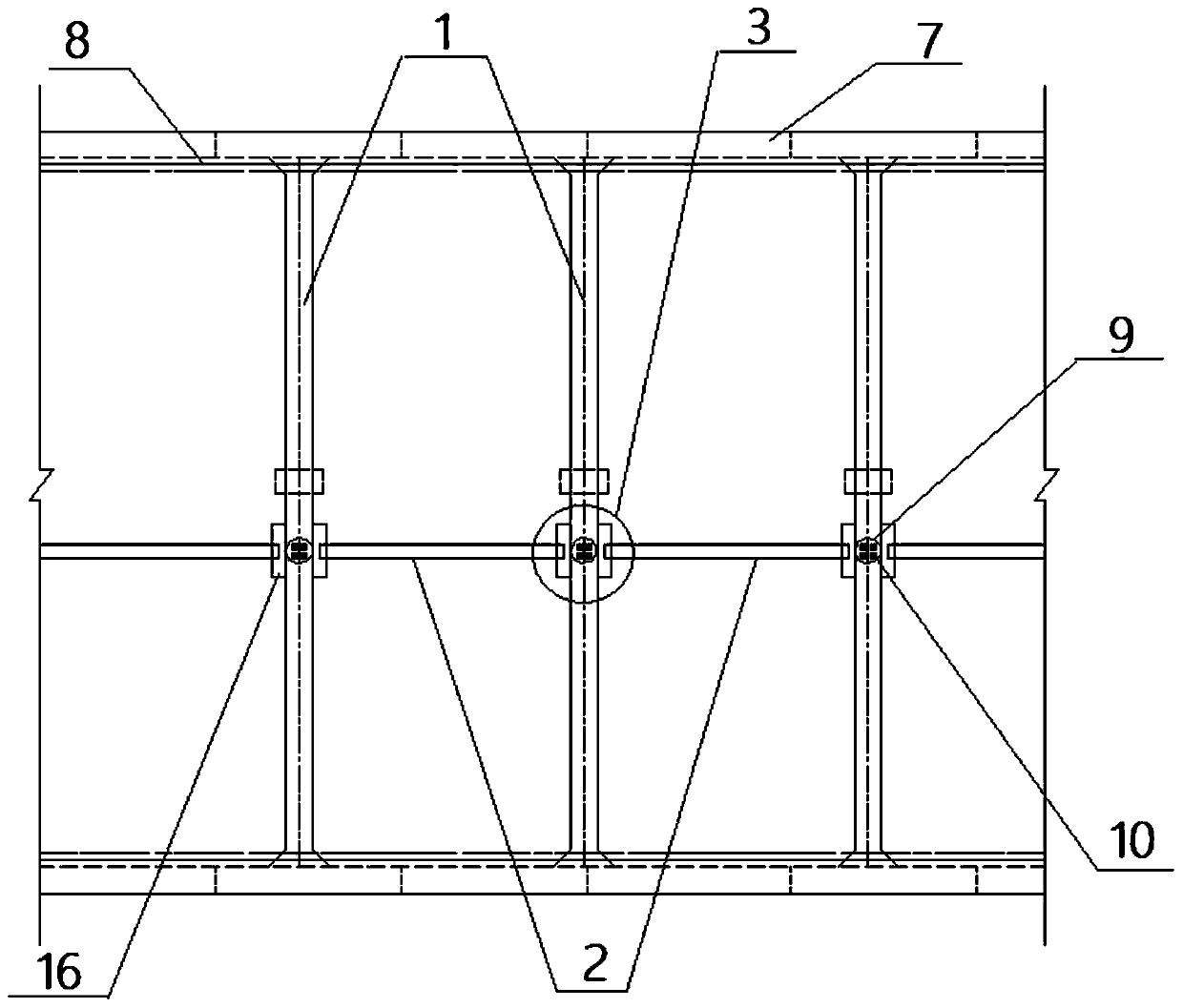

[0034] like Figure 1-3 As shown in the figure, the construction method of the cast-in-situ concrete in the strip foundation pit to support the prefabricated connecting beam, the prefabricated connecting beam in this embodiment is a prefabricated concrete connecting beam, including the following steps:

[0035] A. Factory prefabricated tie beam 2: The length of the precast concrete tie beam 2 is 8-9m, with each increase of 0.1m as a step, the factory prefabricates the precast concrete tie beam 2 with a length of 10 steps in batches. Both ends of the beam 2 are provided with through-bolt insertion holes 21 , and hole edge reinforcing ribs 22 are embedded around the bolt insertion holes 21 .

[0036] B. Construction of foundation pit enclosure structure 7, column piles 9 and temporary steel columns 10;

[0037] The foundation pit enclosure structure is the soil and water retaining structure required for the excavation of the foundation pit. Generally, according to the excavatio...

Embodiment 2

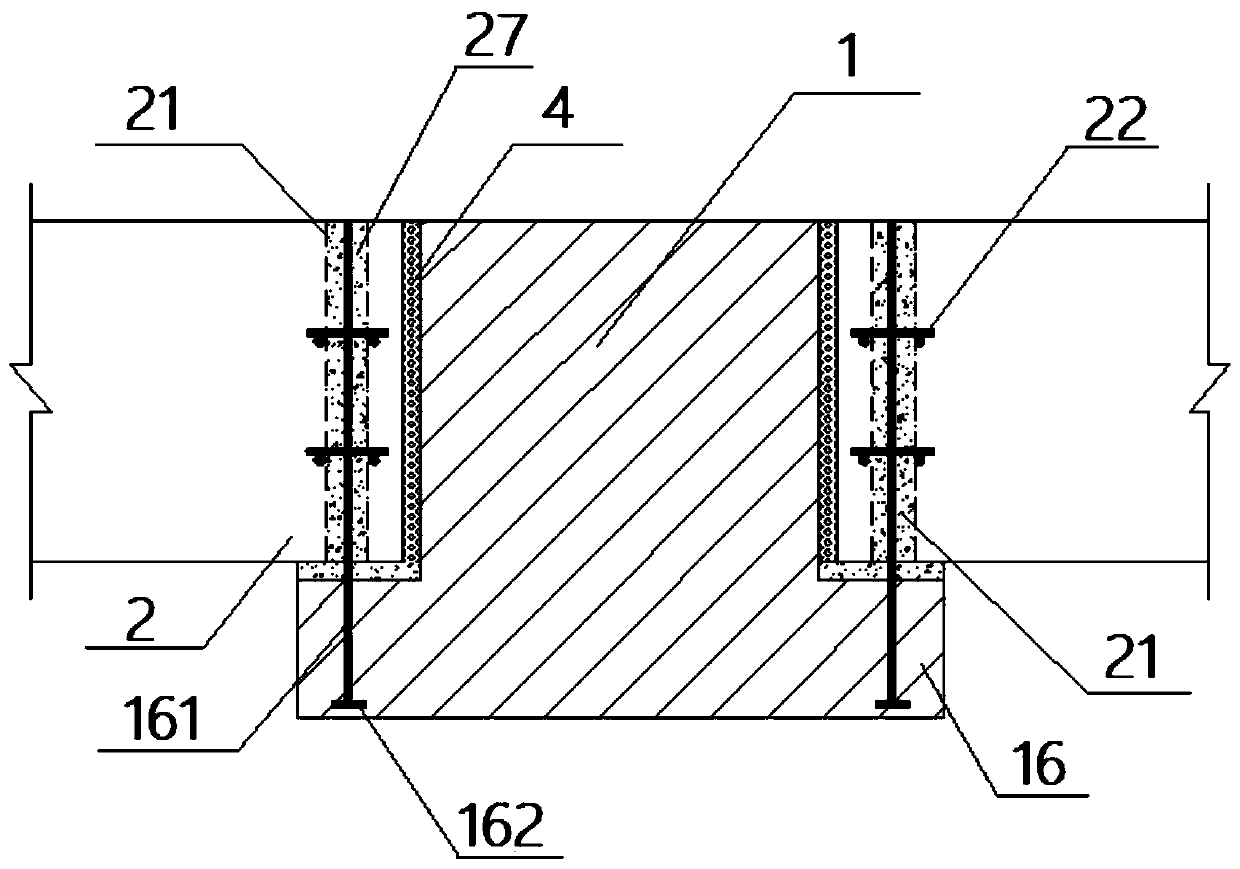

[0043] like Figure 4-6 As shown in the figure, the construction method of the cast-in-situ concrete in the strip foundation pit to support the prefabricated connecting beam, the prefabricated connecting beam in this embodiment is a prefabricated concrete connecting beam, including the following steps:

[0044] A. Factory precast concrete tie beam 2: The length of the precast concrete tie beam 2 is 8-9m, with each increase of 0.1m as a step, the factory prefabricates the precast concrete tie beam 2 with 10 steps of length in batches. Both ends of the tie beam 2 are embedded with tie beam T-shaped embedded parts, and the tie beam T-shaped embedded parts include a tie beam flange 23 and a tie beam web 24 vertically fixed on the tie beam flange 23. The tie beam flange 23 It is vertically embedded in both ends of the precast concrete connecting beam 2, and the reinforcing anchor bars 25 are embedded in the inner side of the connecting beam flange 23; the connecting beam web 24 ext...

Embodiment 3

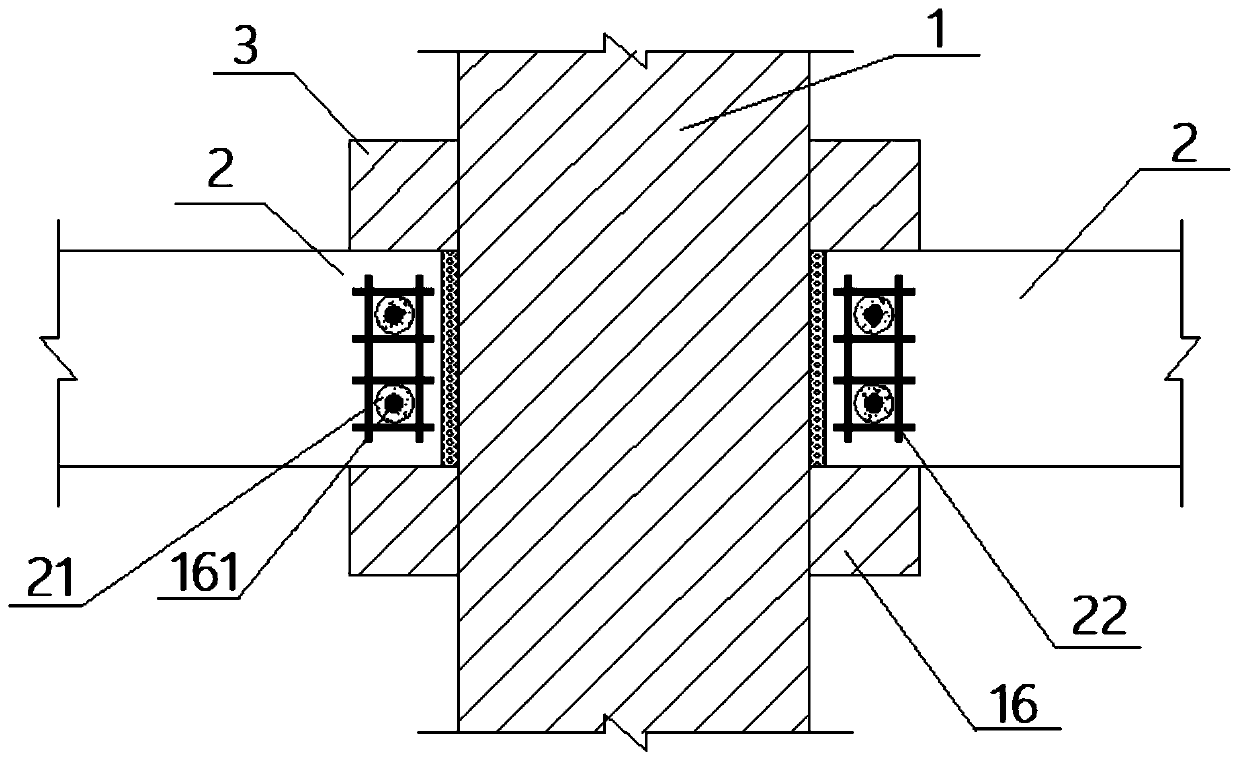

[0052] like Figure 7-9 As shown, the construction method of the cast-in-situ concrete in the strip foundation pit to support the prefabricated tie beam, in this embodiment, the prefabricated tie beam is a prefabricated steel tie beam, including the following steps:

[0053] A. Factory prefabricated steel tie beam 2: The length of the prefabricated steel tie beam 2 is 8-9m, with each increase of 0.1m as a grade, the factory prefabricates 10 prefabricated steel tie beams 2 in length in batches. In this embodiment , the prefabricated steel tie beam is an I-beam beam 2, a connecting steel plate 26 is provided at both ends of the I-beam beam 2, and a connecting steel plate bolt hole 261 is provided on the connecting steel plate 26, and the arrangement of the steel plate bolt holes 261 corresponds to the pair of Arrangement of the support embedded bolts 15; the I-beam 2 can be formed by section steel or by combining steel plates by welding. In this embodiment, the I-beam 2 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com