A Space-Loaded Bearing for Unsymmetrical Cross-Section Bias Tests

A space-loading, asymmetrical technology, applied in the testing, measuring devices, instruments, etc. of machines/structural components, can solve the problems of inconsistent stress state, increase the difficulty of analysis, misalignment, etc., and achieve the effect of simplifying the stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

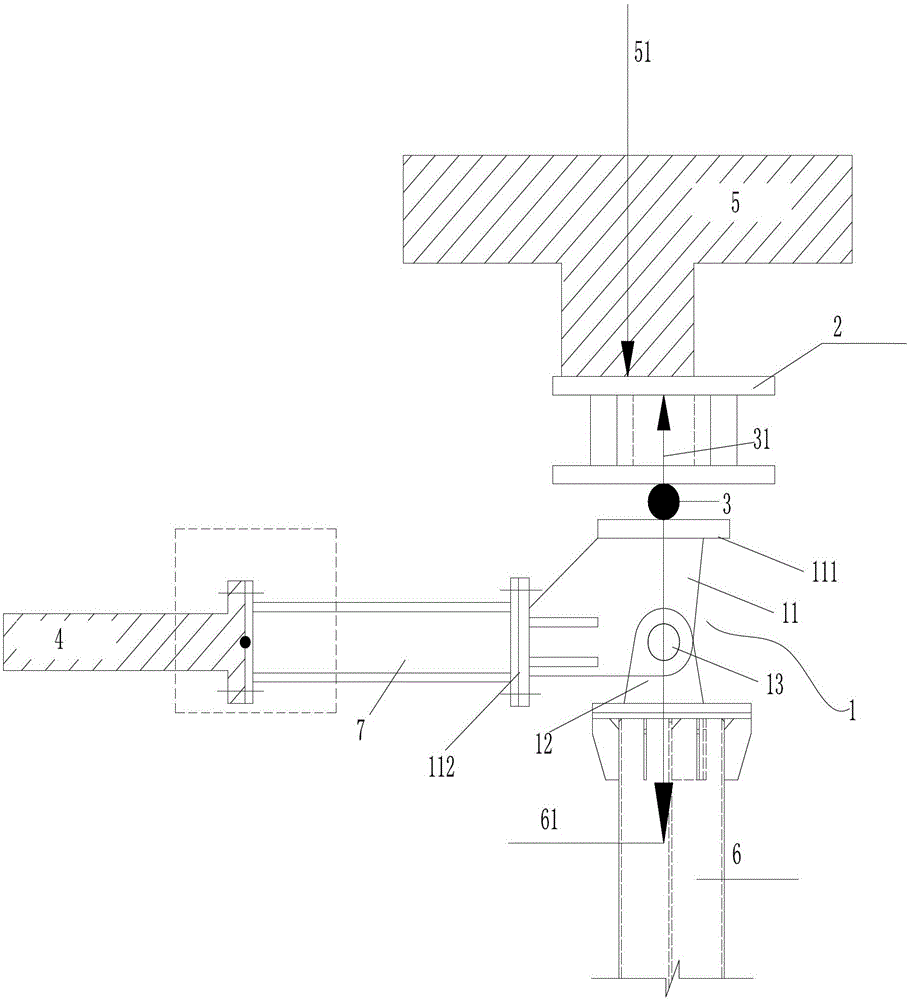

[0013] like figure 1 As described above, a space-loaded support for asymmetric cross-section bias tests includes a pin hinge assembly 1, a conversion device 2, a spherical hinge 3, a horizontal actuator 4, and a vertical actuator 5. The pin hinge assembly 1 It is composed of rotatably connected lug a11 and lug b12. The lug a11 and lug b12 are connected by a pin shaft 13, wherein the lug a11 is provided with an upper top plate 111 and a side plate 112, and the ball hinge 3 is placed on the lug a11 On the upper top plate 111 of the ear plate a11, the conversion device 2 is placed on the ball hinge 3, and the vertical actuator 4 is placed on the conversion device 2. The center of the ball hinge 3 coincides with the centroid of the upper top plate 111 of the ear plate a11. Through the conversion device 2 and the ball The hinge 3 coincides the center of the vertical actuator 5 with the centroid of the lug a11, and at the same time the centroid of the lug a11 coincides with the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com