Hot asphalt adhesive layer for radar measurement of surface thickness and utilization method

A technology of hot asphalt and bonding layer, which is applied in the direction of measuring device, wave/particle radiation, coagulation pavement paved on site, etc., which can solve the problem of increased project cost, the inability to distinguish and detect the thickness of asphalt layer, and the basis for evaluation, etc. Problems, to achieve the effect of improving performance and service life, significant economic and social benefits, and ensuring project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

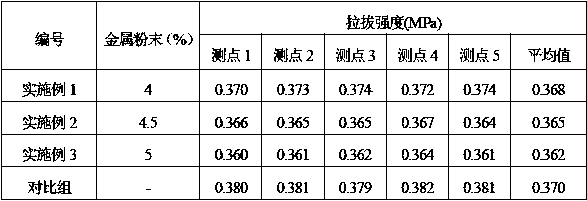

Embodiment 1

[0016] All raw materials and their mass ratios of the thermal asphalt bonding course used for radar measurement of surface layer thickness are as follows:

[0017] Bitumen 100kg

[0019] Thermoplastic resin 2.5kg

[0020] Anti-stripping agent 1.25kg

[0021] Antioxidant 0.3kg

[0022] Coupling agent 0.25kg

[0023] The asphalt is SBS polymer modified asphalt, the metal powder is iron powder with a particle size of 0.05 mm; the thermoplastic resin is ethylene-vinyl acetate copolymer (EVA); the anti-stripping agent is slaked lime with a particle size of 0.06 mm; the antioxidant is Dibutylhydrocarbyl toluene; coupling agent is silane coupling agent KH-560.

Embodiment 2

[0025] All raw materials and their mass ratios of the thermal asphalt bonding course used for the radar to accurately measure the thickness of the surface layer are as follows:

[0026] Bitumen 100kg

[0027] Metal powder 4.5kg

[0028] Thermoplastic resin 2.5kg

[0029] Anti-stripping agent 1.5kg

[0030] Antioxidant 0.3kg

[0031] Coupling agent 0.25kg

[0032] The above-mentioned asphalt, metal powder, thermoplastic resin, anti-stripping agent, antioxidant and coupling agent are the same as in Example 1, and the method of using the hot asphalt bonding layer is the same as in Example 1.

Embodiment 3

[0034] All raw materials and their mass ratios of the thermal asphalt bonding course used for the radar to accurately measure the thickness of the surface layer are as follows:

[0035] Bitumen 100kg

[0036] Metal powder 5kg

[0037] Thermoplastic resin 2.5kg

[0038] Anti-stripping agent 1.75kg

[0039] Antioxidant 0.3kg

[0040] Coupling agent 0.25kg

[0041] The above-mentioned asphalt, metal powder, thermoplastic resin, anti-stripping agent, antioxidant and coupling agent are the same as in Example 1; the method of use is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com