Aluminum alloy extrusion die for pre-running mould

An extrusion die and aluminum alloy technology, applied in the direction of metal extrusion dies, etc., can solve the problems of easy crooked cantilever, affecting the appearance, easy to break, etc., and achieve the effect of overcoming convex road defects, reasonable structural design, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

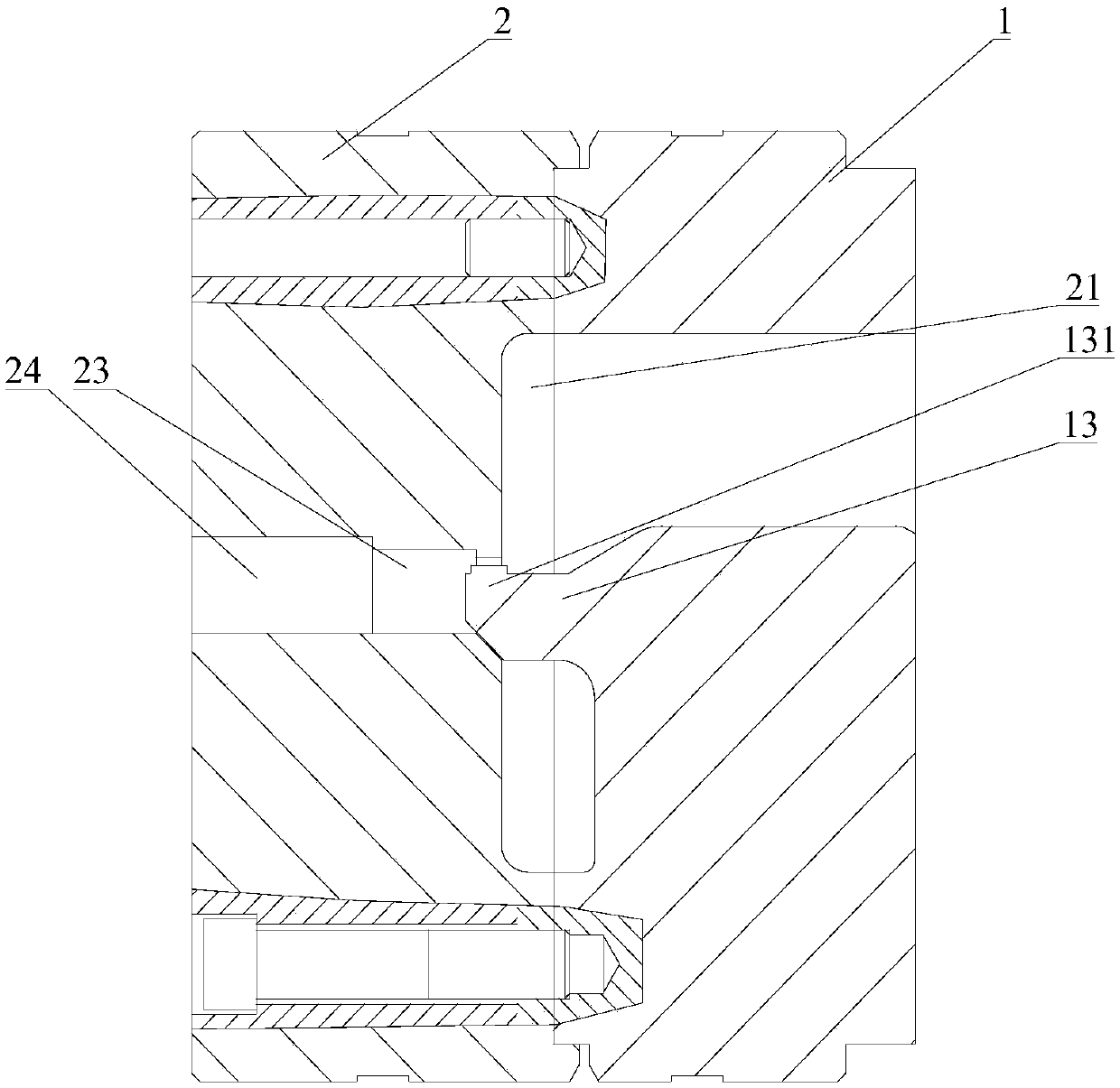

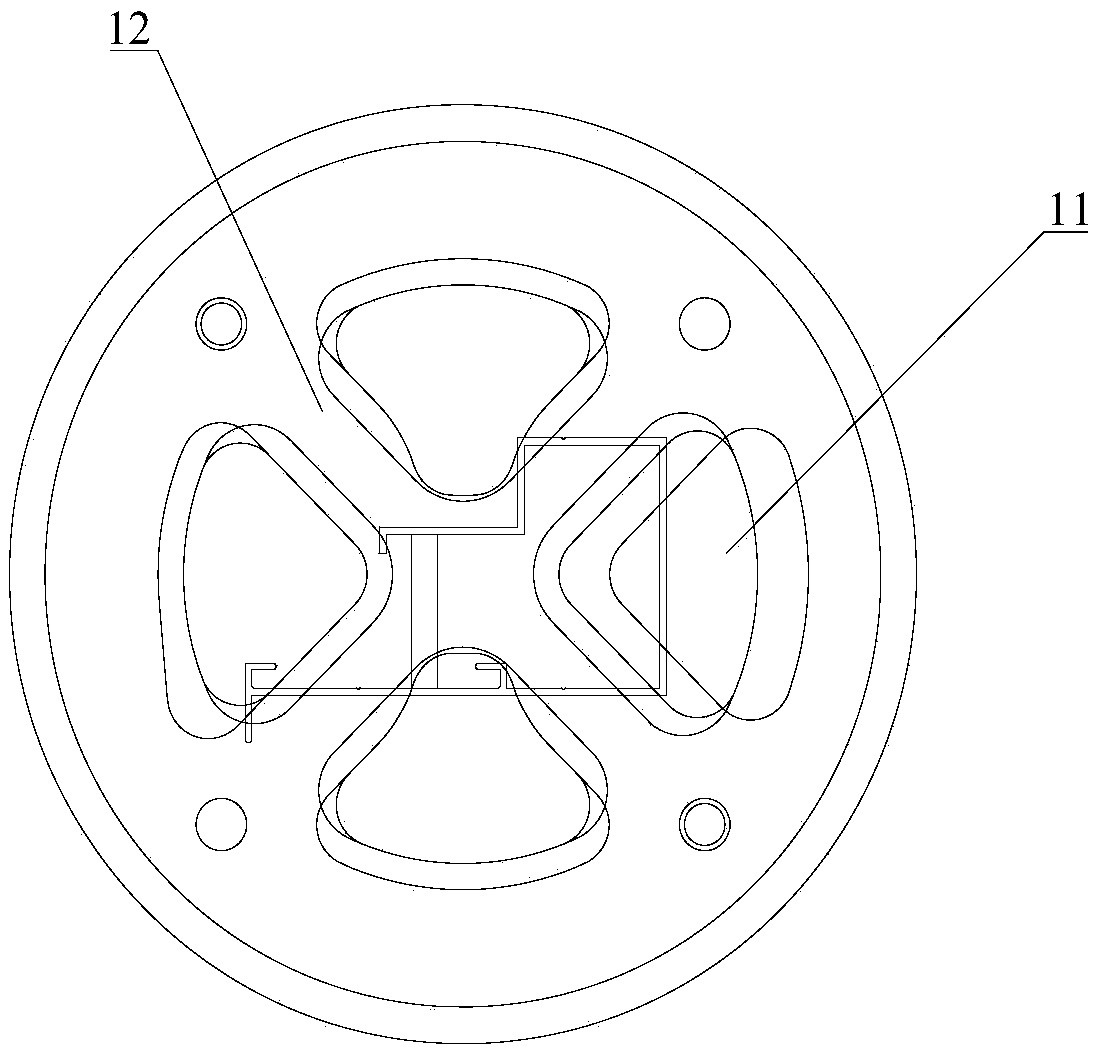

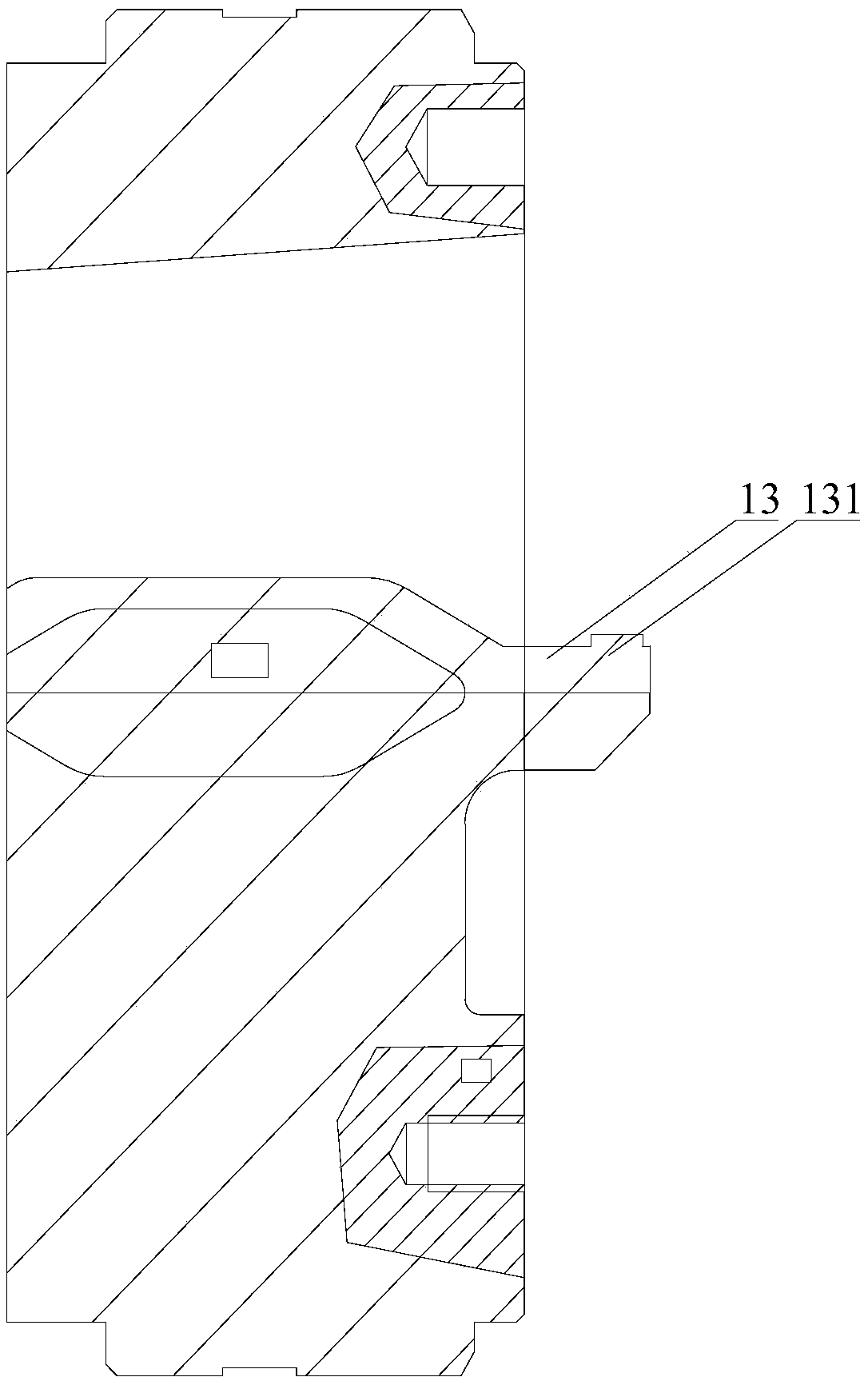

[0016] In order to describe in detail the technical content, the achieved objectives and effects of the present invention, the following description will be given in conjunction with the embodiments and the accompanying drawings.

[0017] A pseudo-split die aluminum alloy extrusion die, comprising an upper die and a lower die. A plurality of shunt bridges are distributed on the supply surface of the upper die, and shunt holes are formed between adjacent shunt bridges. The center of the upper die A tongue core extending into the lower mold is provided, the tongue core includes a first working belt, and the overlapping surface of the first working belt is an inclined surface;

[0018] The feed surface of the lower mold is provided with a welding chamber, the discharge surface is provided with an outlet empty knife, a second working belt is arranged between the welding chamber and the outlet empty knife, and the overlap of the second working belt The surface is a slope parallel to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com