A method for hydrolyzing spider dry powder and anti-inflammatory and anti-moth toothpaste containing spider dry powder hydrolyzate

A hydrolyzate and spider technology, which is applied in the field of food and daily chemicals, can solve the problems that the product has not been seen in patents and literature reports, and achieve the effect of good dental caries, good effect and high degree of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

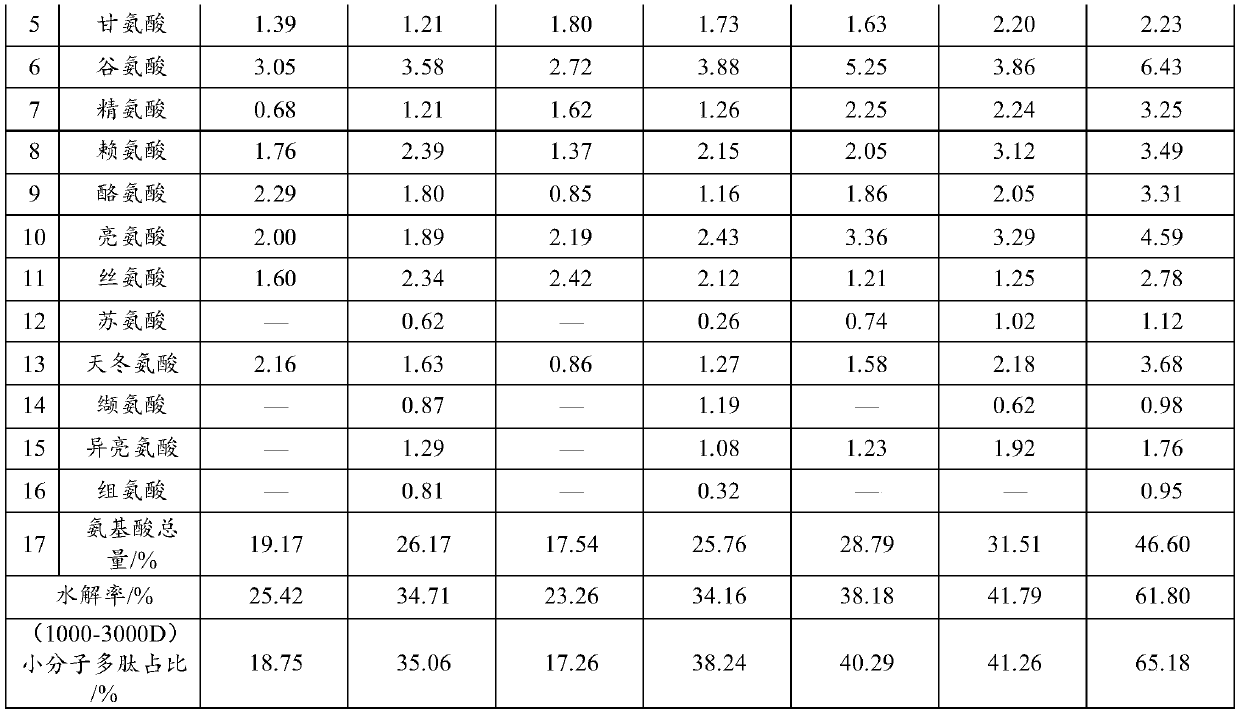

Examples

preparation example Construction

[0064] 2.2 Preparation of dried spider powder

[0065] 2.2.1. Pick out spiders with a body length of more than 5cm 10 days in advance for disinfection and isolation, and stop feeding to make them exhaust the excrement in their bodies. Disinfect the spider body, the breeding tank and the breeding environment with a potassium permanganate solution with a concentration of 1% every three days, and disinfect twice in total;

[0066] 2.2.2. Before harvesting spiders, prepare clean basins filled with pure water, 500mL plastic cups with lids, tweezers, washing bottles, trays and other supplies;

[0067] 2.2.3. When harvesting spiders, use tweezers to clamp the spiders out of the breeding barrel or box, put them into plastic cups, and cover them;

[0068] 2.2.4. Put the spiders into a freezer at -18°C and freeze them for 24 hours to kill them;

[0069] 2.2.5. Dry the spiders that have been frozen to death in an electric oven at a temperature of 60-70°C until the moisture content is l...

Embodiment 1

[0084] 1. Harvesting of whole insects of spiders

[0085] 1.1. Pick out spiders with a body length of more than 5cm 10 days in advance for disinfection and isolation, and stop feeding to make them exhaust the excrement in the body. Disinfect the spider body, the breeding tank and the breeding environment with a potassium permanganate solution with a concentration of 1% every three days, and disinfect twice in total;

[0086] 1.2. Before harvesting spiders, prepare clean basins filled with pure water, 500mL plastic cups with lids, tweezers, washing bottles, trays and other supplies;

[0087] 1.3. When harvesting spiders, use tweezers to clamp the spiders out of the breeding barrel or box, put them into plastic cups, and cover them;

[0088] 1.4. Put the spiders into a freezer at -18°C and freeze them for 24 hours to kill them;

[0089] 1.5. Take the frozen spider to the laboratory and put it in a clean basin filled with pure water for rinsing, and use a brush to scrub its bod...

Embodiment 2

[0112] 1. Harvesting of whole insects of spiders

[0113] With embodiment 1.

[0114] 2. Preparation of spider freeze-dried powder

[0115] With embodiment 1.

[0116] 3. Hydrolysis process of spider freeze-dried powder

[0117] 3.1 Take 10g of spider freeze-dried powder, add 250mL of purified water, stir evenly, and heat to 52°C, while using 0.1mol / L NaOH or 0.1mol / L HCl to adjust the pH to 7.2;

[0118] 3.2 Add neutral protease (enzyme activity 100,000 U / g-200,000 U / g) 9000U / g, 52°C, pH 7.2, hydrolyze for 4.2h;

[0119] 3.3 Centrifuge for 20 minutes at a speed of 5000r / min to separate hydrolyzate A and spider powder raw materials;

[0120] 3.4 Heat the hydrolyzate A to 90°C for 15 minutes to inactivate the enzyme, then cool to room temperature;

[0121] 3.5 Add 250mL of purified water to the separated spider powder raw material, stir evenly, and heat to 52°C, while adjusting the pH to 9.2 with 0.1mol / L NaOH;

[0122] 3.6 Add alkaline protease (enzyme activity 100,000 U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com