Flexible mannequin and making method thereof

A flexible, mannequin technology, applied in the field of mannequins, can solve the unfavorable clothing production, the development of the sales market, the garment display effect, the unfavorable design and technical personnel's mannequin clothing making, sewing and processing, and the lack of softness of human skin on mannequins And elasticity and other issues, to achieve the effect of improving the realism of fitting, good waterproof effect and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

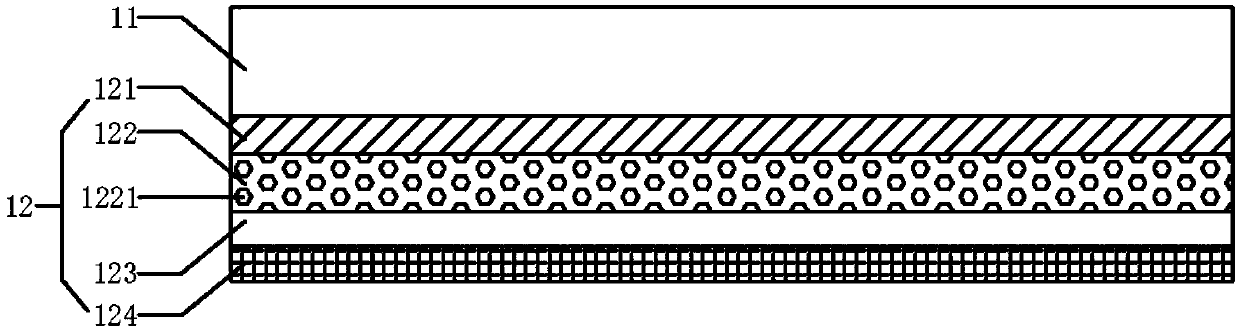

[0043] See Figure 1-2 , a flexible mannequin, the flexible mannequin 1 includes a mannequin body 11 and a flexible outer layer 12, the flexible outer layer 12 includes a silicone cotton layer 121, a memory foam layer 122 and a waterproof cotton layer connected sequentially from the inside to the outside 124 , the inner surface of the silicone cotton layer 121 is connected to the outer surface of the mannequin body 11 , and a viscose layer 123 is arranged between the memory foam layer 122 and the waterproof cotton layer 124 .

[0044] The thickness of the silica gel cotton layer 121 is 0.5 cm, and the thickness of the memory foam layer 122 is 4 cm.

[0045] The waterproof cotton layer 124 is a PVC waterproof cotton layer.

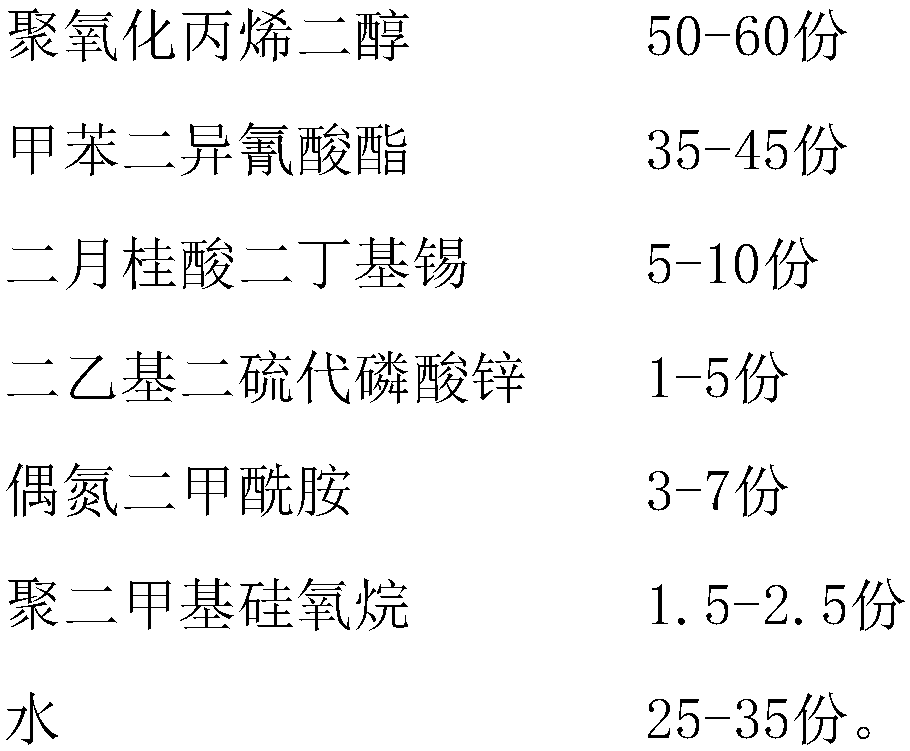

[0046] The memory foam layer is made of polyurethane and nano-silicon particles in a weight ratio of 3:1, and the polyurethane is made of the following raw materials in parts by weight:

[0047]

[0048] Described memory foam layer is made by following...

Embodiment 2

[0068] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0069] The thickness of the silica gel cotton layer 121 is 0.85 cm, and the thickness of the memory foam layer 122 is 3.5 cm.

[0070] The memory foam layer is made of polyurethane and nano-silicon particles in a weight ratio of 3.8:1, and the polyurethane is made of the following raw materials in parts by weight:

[0071]

[0072]

[0073] Described memory foam layer is made by following preparation method:

[0074] Step 1: Dissolving dibutyltin dilaurate in water, then adding polyoxypropylene diol and toluene diisocyanate, and stirring at 48°C for 45 minutes to obtain a polyurethane prepolymer;

[0075] Step 2: Heat the polyurethane prepolymer prepared in step 1 to 80°C, then add zinc diethyldithiophosphate, polydimethylsiloxane and azodicarbonamide in sequence, at a speed of 300-1000rpm Stir for 25 minutes, add nano-silicon particles while stirring, and form and cool to obtain a...

Embodiment 3

[0091] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0092] The thickness of the silica gel cotton layer 121 is 1.25 cm, and the thickness of the memory foam layer 122 is 3 cm.

[0093] The memory foam layer is made of polyurethane and nano-silicon particles in a weight ratio of 4.5:1, and the polyurethane is made of the following raw materials in parts by weight:

[0094]

[0095] Described memory foam layer is made by following preparation method:

[0096] Step 1: Dissolving dibutyltin dilaurate in water, then adding polyoxypropylene diol and toluene diisocyanate, and stirring at 52°C for 40 minutes to obtain a polyurethane prepolymer;

[0097] Step 2: Heat the polyurethane prepolymer prepared in step 1 to 90°C, then add zinc diethyldithiophosphate, polydimethylsiloxane and azodicarbonamide in sequence, and stir at 825rpm After 30 minutes, add nano-silicon particles while stirring, and form and cool to obtain a memory foam layer.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com