Aquaculture nutrient solution adding device

An adding device and aquaculture technology, applied in fish farming, transportation and packaging, mixers, etc., can solve the problems of large stirring range, increase of dissolved oxygen, waste, etc., to improve utilization rate, increase the effect of addition, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

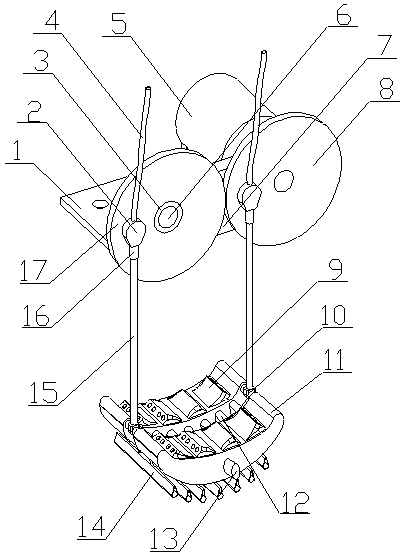

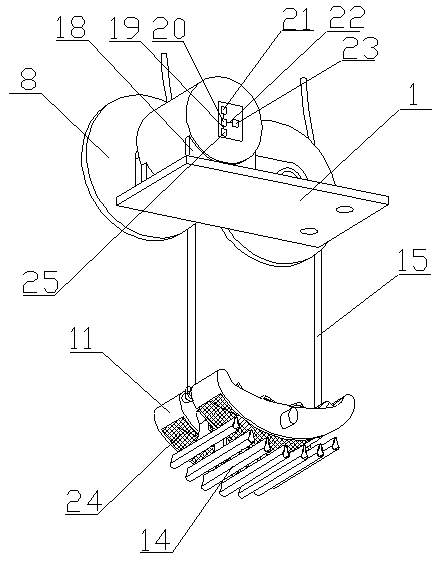

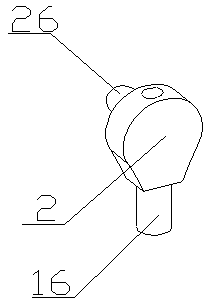

[0032] An aquaculture nutrient solution adding device of the present invention is realized in this way. When in use, when adding nutrient solution to the aquaculture waters, the fixed plate (1) is first installed and fixed on the fixed plate (1) through the two mounting holes on the fixed plate (1). Connect the two liquid inlet pipes (4) to the external nutrient solution pipes at appropriate positions, lower the two mixing plates (11) into the water body, and the nutrient solution enters the connecting block ( 2), and then flow into the connected diversion tube (15), and then flow into the two mixing plates (11) through the corresponding rotating tube (27). The heating plate on the inner wall of the mixing plate (11) works to The nutrient solution in the mixing plate (11) is heated to quickly dissolve the sediment in the nutrient solution,

[0033] The present invention also relates to a method for adaptively adjusting the swing speed of the mixing plate (11), which is charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com