Method for controlling quality of intaglio printing special color and halftone images

A technology of gravure printing and image quality, applied in printing, color/spectral property measurement, printing plate preparation, etc., it can solve the problem of insufficient accuracy, difficulty in judging plate-making dots, color matching, or printing, and inability to unify standards, etc. problems, to avoid the long training cycle, simple judgment, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of gravure printing image quality control method, comprises the steps:

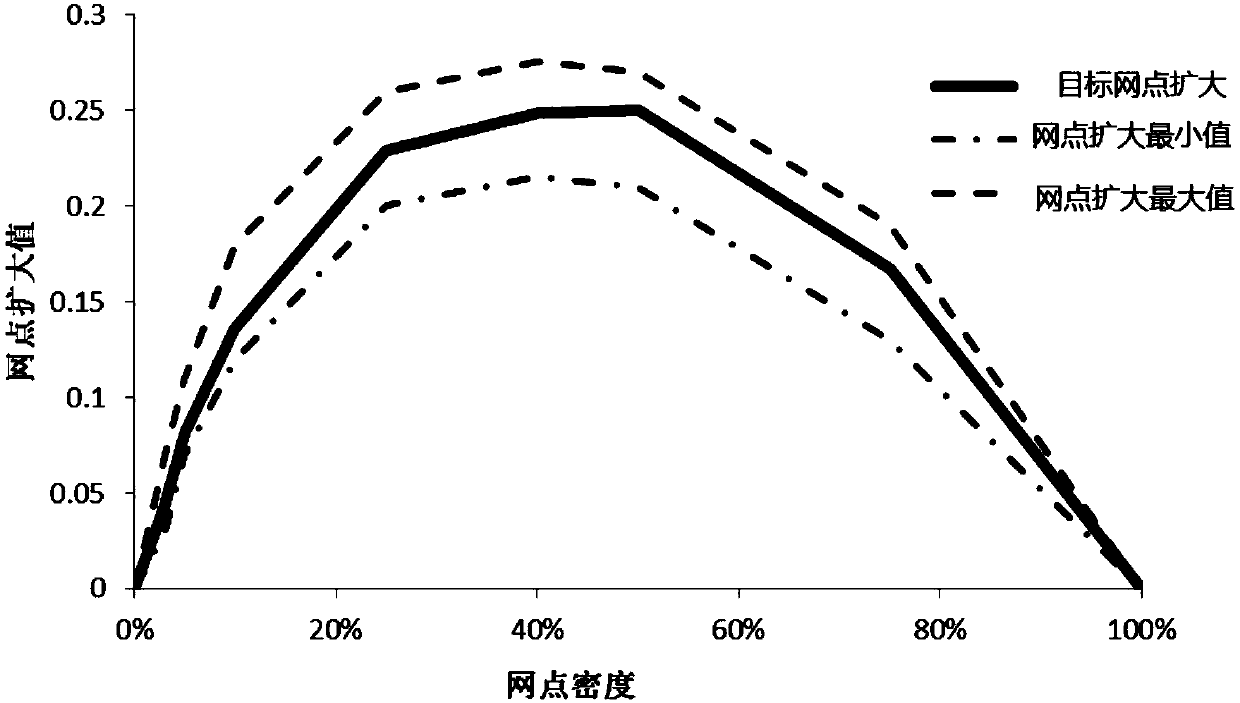

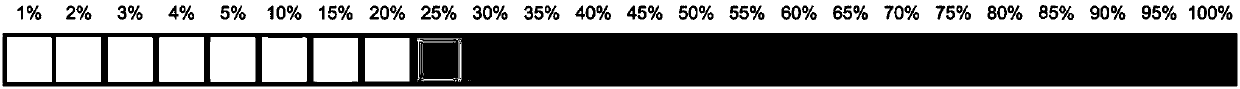

[0039] Step 1: Make a monochrome color card within the range of K standard dot gain, such as figure 2 As shown, the presentation of different colors produced by meshing from 0 to 100%. As shown in Table 1, set the standard dot gain minimum Min DG and dot gain Max DG for typical dots, Tatget Dot Gain is the standard dot gain, Tolerance: + / - is the dot spread tolerance.

[0040] Table 1

[0041]

[0042]

[0043] Step 2: K color card dot expansion printing test:

[0044] Print the monochrome color card on the printing machine with black ink. At this time, it is necessary to determine the manufacturer of the ink and determine the printing process parameters. After several experiments on the machine, the dot gain is between the two lines of Min DG and Max DG. At the same time Measured 0-100% network layer density value, that is, the color density restoration curve, such as figure 1 sh...

Embodiment 2

[0053] The steps are the same as in Embodiment 1, the difference is that the outlets in step 3 are selected from 100%, 60%, 20%, and 3% outlets.

Embodiment 3

[0055] The steps are the same as in Embodiment 1, the difference is that the outlets in step 3 are selected from 100%, 85%, 55%, and 10% outlets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com