Use of low temperature boiling technology in alcohol production

A low-temperature, alcohol-based technology, applied in microorganism-based methods, microorganisms, biofuels, etc., can solve the problems of reduced starch purity, many by-products, complex production processes, etc., and achieve high cost-effective products, simple equipment, and scientific and reasonable methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

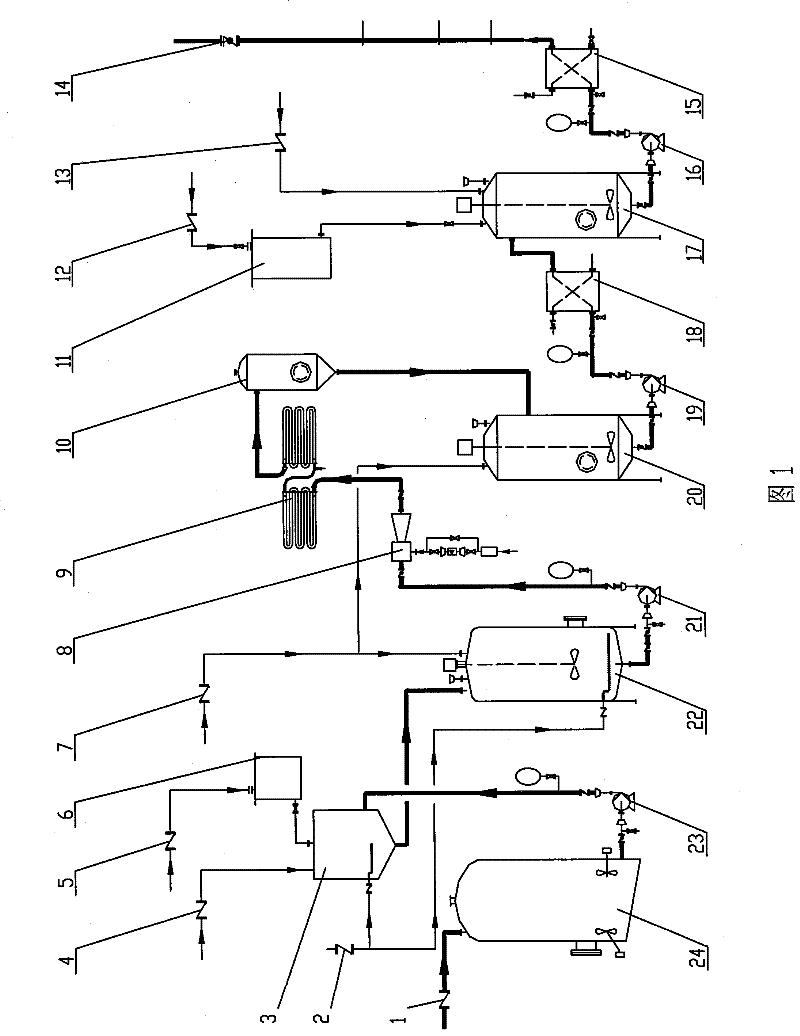

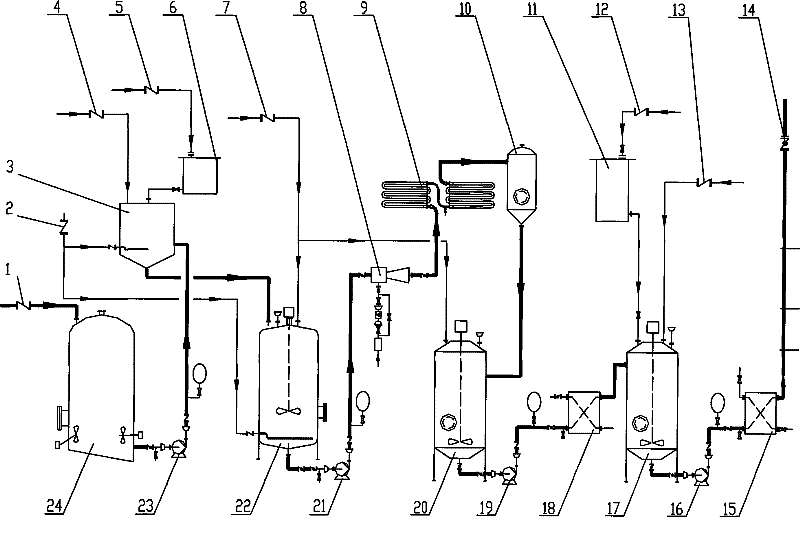

[0022] refer to figure 1 , the starch milk enters the starch milk storage tank 24 through the starch milk valve 1, and is pumped into the precooking tank 3 with the starch milk pump 23, and the ammonia enters the ammonia water high level tank 6 through the valve 5, and then enters the precooking tank 3, and the pH value is adjusted to 5.8 to 6.5, at the same time, steam is added to the pre-cooking tank 3 through the steam valve 2, and the temperature is adjusted to 45-50°C. The process water that meets the GB / T19923-2005 standard also enters the pre-cooking tank 3 through the valve 4, and the starch milk The concentration is adjusted to 11-13 degrees Baume (i.e., the dry matter content is 19.5-23%), the feed liquid from the pre-cooking tank 3 flows into the pre-liquefaction tank 22 by itself through the height difference, and the liquefying enzyme (genencor product) passes through The liquefaction enzyme valve 7 enters the pre-liquefaction tank 22. At the same time, steam is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com