Zwitterion-contained copolymer compounded natural gas hydrate inhibitor and preparation method thereof

A hydrate inhibitor, zwitterion technology, used in mechanical equipment, gas/liquid distribution and storage, piping systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

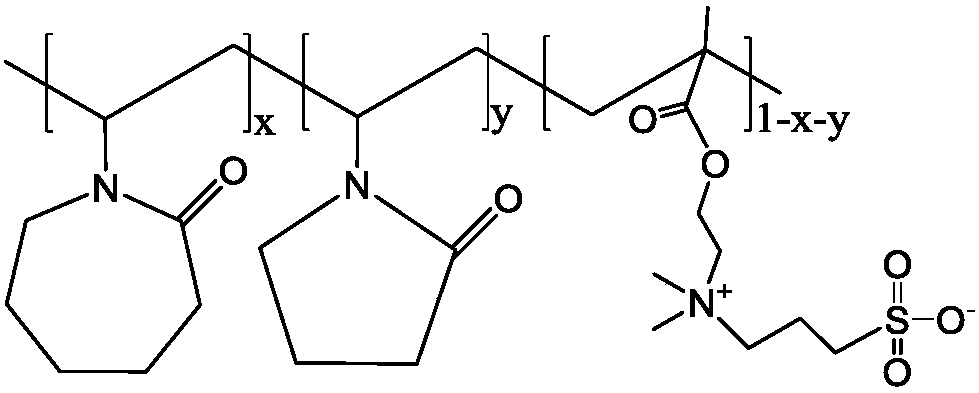

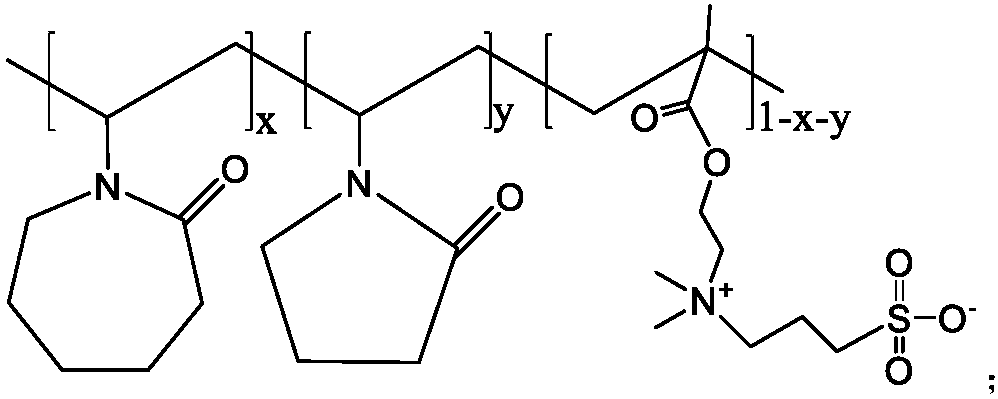

[0023] (1) Preparation of zwitterionic copolymer P(VCap-co-VP-co-SBMA):

[0024] In a reaction flask equipped with magnetic stirring, vinylcaprolactam (1.2mmol), vinylpyrrolidone (0.6mmol), sulfobetaine methacrylate (0.2mmol), tetramethylethylenediamine (10μL) and Ammonium sulfate (10mg) was dissolved in a mixed solvent of DMSO and water with a volume ratio of 1:1, the reaction temperature was 20°C, and the reaction time was 30h. After the reaction was terminated, it was dialyzed with MWCO, and then freeze-dried to obtain a radical polymerized copolymer P(VCap-co-VP-co-SBMA) with a molecular weight of 10,000, and x / y=0.5.

[0025] (2) Preparation of compound natural gas hydrate inhibitor containing zwitterionic copolymer:

[0026] The copolymer P(VCap-co-VP-co-SBMA) with a molecular weight of 10000, which accounts for 0.1% of the system, is compounded with the thermodynamic inhibitor methanol at a mass ratio of 1:1 to obtain a compound type containing zwitterionic copolymers ...

Embodiment 2

[0029] (1) Preparation of zwitterionic copolymer P(VCap-co-VP-co-SBMA):

[0030] In a reaction flask equipped with magnetic stirring, vinylcaprolactam (2.4mmol), vinylpyrrolidone (1.2mmol), sulfobetaine methacrylate (0.4mmol), tetramethylethylenediamine (15μL) and Ammonium sulfate (15mg) was dissolved in a mixed solvent of DMSO and water with a volume ratio of 1:3, the reaction temperature was 30°C, and the reaction time was 40h. After the reaction stopped, it was dialyzed with MWCO, and then freeze-dried to obtain a free-radical copolymer P(VCap-co-VP-co-SBMA) with a molecular weight of 15,000, and x / y=1.8.

[0031] (2) Preparation of compound natural gas hydrate inhibitor containing POSS amphiphilic copolymer:

[0032] The copolymer P(VCap-co-VP-co-SBMA) with a molecular weight of 15000 accounting for 1% of the system is compounded with the thermodynamic inhibitor ethanol at a mass ratio of 1:10 to obtain a compound type containing zwitterionic copolymer Gas hydrate inhibi...

Embodiment 3

[0035] (1) Preparation of zwitterionic copolymer P(VCap-co-VP-co-SBMA):

[0036] In a reaction flask equipped with magnetic stirring, vinylcaprolactam (3.6mmol), vinylpyrrolidone (1.8mmol), sulfobetaine methacrylate (0.6mmol), tetramethylethylenediamine (20μL) and Ammonium sulfate (20mg) was dissolved in a mixed solvent of DMSO and water with a volume ratio of 1:5, the reaction temperature was 40°C, and the reaction time was 50h. After the reaction stopped, it was dialyzed with MWCO, and then freeze-dried to obtain a radical polymerized copolymer P(VCap-co-VP-co-SBMA) with a molecular weight of 30,000, and x / y=3.0.

[0037] (2) Preparation of compound natural gas hydrate inhibitor containing zwitterionic copolymer:

[0038] The copolymer P(VCap-co-VP-co-SBMA) with a molecular weight of 30000 accounting for 2% of the system was compounded with the thermodynamic inhibitor ethylene glycol at a mass ratio of 1:20 to obtain a compound containing zwitterionic copolymers. Formulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com