Large section steel box beam amplitude-selection matching structure and manufacturing method

A matching structure and steel box girder technology, which is applied in the field of steel bridge manufacturing, can solve problems such as the inability to install beams, increase the transportation cost of steel box girders, and difficulty in adapting to changes in the width of steel box girders, and achieve the effect of ensuring manufacturing quality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

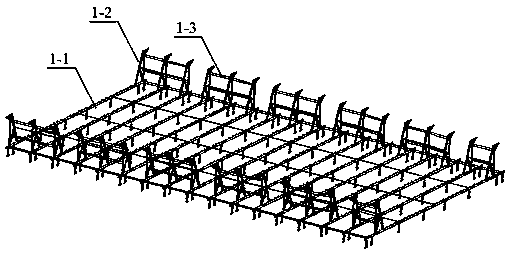

[0014] Embodiment 1: with reference to attached figure 1 . A large-segment steel box girder framing matching structure, the diagonal braces 1-2 of the steel box girder general tire frame are designed as a group of 3, and the diagonal braces 1-2 in each group are connected by tie rods 1-3. Integral diagonal brace frame, the lower ends of the three diagonal braces at the lower ends of the two sets of integral diagonal brace frames are respectively connected to the crossbeam 1-1, and the crossbeam at the bottom of the diagonal brace 1-2 is provided with an anti-overturning sliding device (anti-overturning sliding device It belongs to the prior art in the steel structure, so it will not be described in detail), and at the same time, a pin locking device is provided at the bottom of the brace (the pin locking device is a common temporary fixing method, so it will not be described here). The width of the steel box girder is to push and slide the diagonal bracing of the overall tire...

Embodiment 2

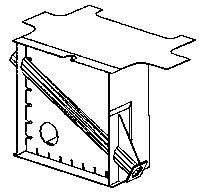

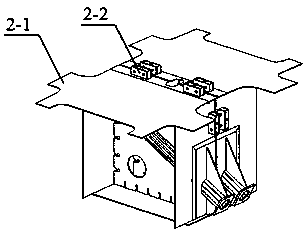

[0015] Embodiment 2: on the basis of embodiment 1, with reference to accompanying drawing 2 and 3. diagram 2-1 is a schematic diagram of the left half of the steel box girder connecting beam, Figure 2-2 Schematic diagram of temporary fittings for connecting beams; Figure 3-1 is a schematic diagram of a detached double box-section steel box girder (without connecting beams installed), Figure 3-2 Schematic diagram of matching fabrication of large segment steel box girders, Figure 3-3 It is a half-width large-segment steel box girder.

[0016] Step 1: Before the board unit is placed on the tire frame, firstly verify the part number of the board unit and check the external dimensions to ensure that the assembly position of the board unit is correct.

[0017] Step 2: Adjust the width of the total tire frame according to the width of the steel box girder, which is "the width of the steel box girder + δ" ('δ' is between two large section steel girders to ensure the assembly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com