A single-station stirring and oscillating device for oil extraction

An oscillating device, oil extraction technology, applied in the direction of oil/fat production, fat production, etc., can solve the problems of reduced oil precipitation rate, unfavorable large-scale production, single stirring function, etc., achieves large driving force, realizes rapidity and convenience The effect of high-efficiency stirring and shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

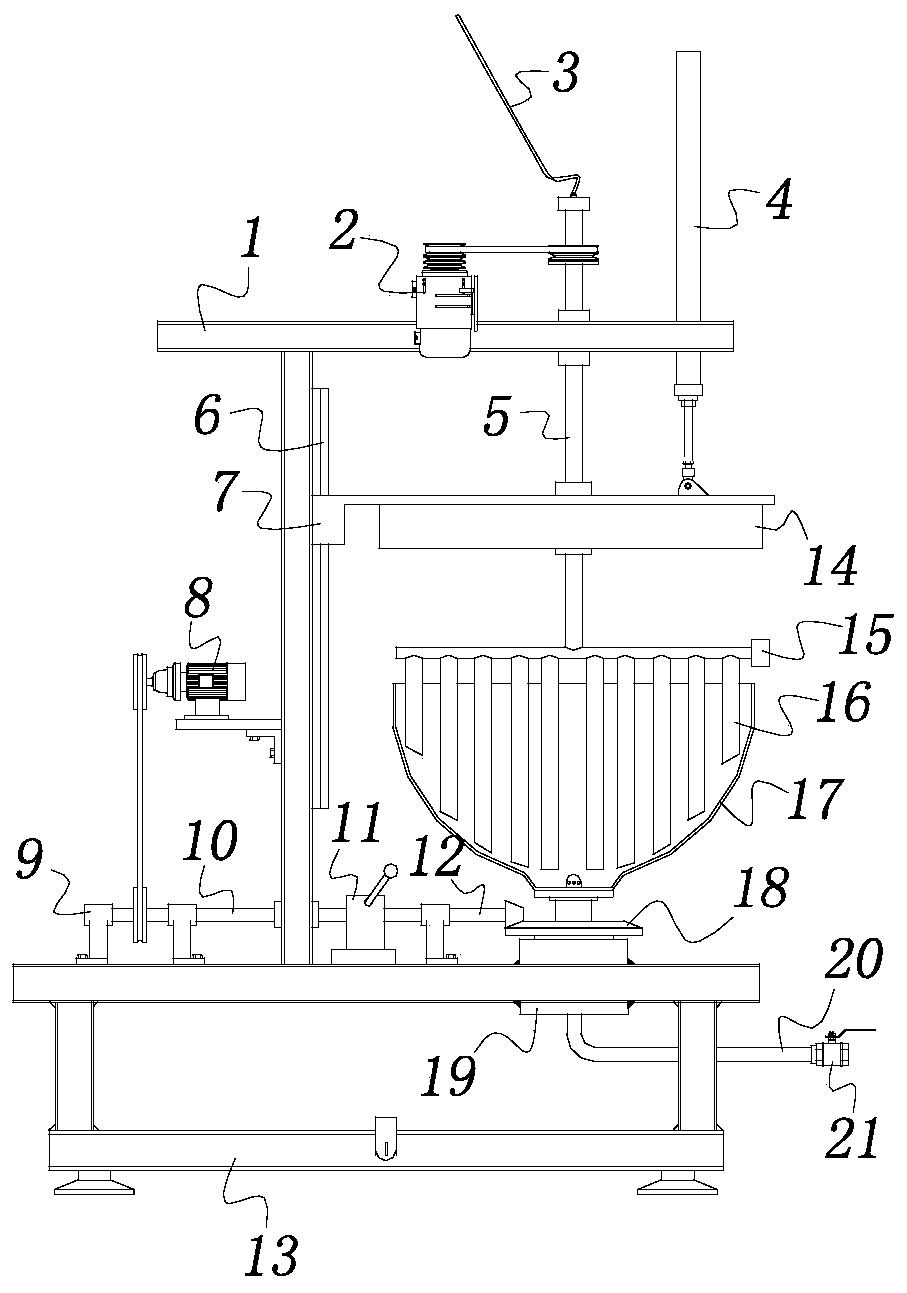

[0016] See figure 1 The single-station stirring and oscillating device for oil extraction of the present invention includes a frame 13, a top beam 1 is supported by a column on the top of the frame 13, and a vertical shaft sleeve 19 is also provided on the frame 13.

[0017] It also includes an extraction tank 17 with a hollow shaft at the bottom. The bottom of the extraction tank 17 is arc-shaped and the top is open. The hollow shaft of the extraction tank 17 is located in the shaft sleeve 19 and a bearing is provided between the hollow shaft and the shaft sleeve 19. . The effect of designing the extraction tank 17 into a circular arc shape is to make the content material flow to the middle of the bottom wall under the action of gravity, so as to facilitate collection and discharge.

[0018] It also inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com