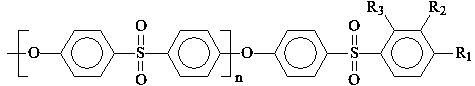

Polyether sulfone resin containing methoxy diphenyl sulfone ether group and its synthesis method and application

A technology containing methoxy diphenyl sulfone ether and methoxy diphenyl sulfone ether, which is applied in the field of polyether sulfone resin containing methoxy diphenyl sulfone ether group and its synthesis, and can solve the problem of reducing the content of chlorine end groups, Low fluidity, hidden dangers in normal use, etc., to achieve the effect of improving transparency and color level, high thermal stability, and improving the degree of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

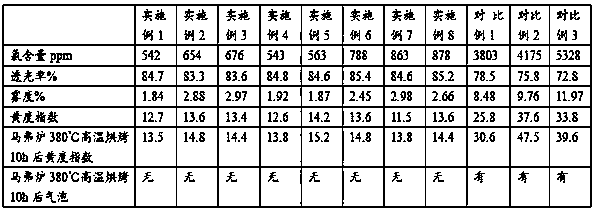

Examples

Embodiment 1

[0031] Add 7.508kg (30mol) of 4,4'-dihydroxydiphenylsulfone, 8.787kg (30.6mol) of 4,4 '-Dichlorodiphenyl sulfone, then add 32.62kg of sulfolane, stir and heat up to 100°C to dissolve the monomer until the solution is transparent, 3.505kg (33mol) salt-forming agent Na 2 CO 3 , then add 2L of xylene, continue to stir and heat up until the salt-forming reaction begins, the azeotrope generated by the water and xylene in the system is blown out by the protective gas, condensed and dropped to the water separator for stratification, and the upper layer Xylene was refluxed into the system again; maintain the temperature in the range of 200°C-210°C, when the collected water was close to the theoretical value (540g), continue to reflux for another 20 minutes, no water drops were observed, proving that the salt formation was complete, and then Distill and release xylene, gradually raise the temperature to 230°C to start the polymerization reaction, after constant temperature for 2.5 hou...

Embodiment 2

[0033] The 0.344 kg (1.2 mol) sodium p-methoxydisulfone phenolate added in the later stage of polymerization was replaced with 0.344 kg (1.2 mol) sodium m-methoxydisulfone phenolate, and the rest of the preparation process conditions were the same as in Example 1.

Embodiment 3

[0035] The 0.344 kg (1.2 mol) sodium p-methoxydisulfone phenolate added in the later stage of polymerization was replaced with 0.344 kg (1.2 mol) sodium o-methoxydisulfone phenolate, and the rest of the preparation process conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com