Method for operating an injection-moulding machine

An injection molding machine and cavity technology, used in the field of running injection molding machines, can solve problems such as uneven mold filling, reduction of injection volume, and insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

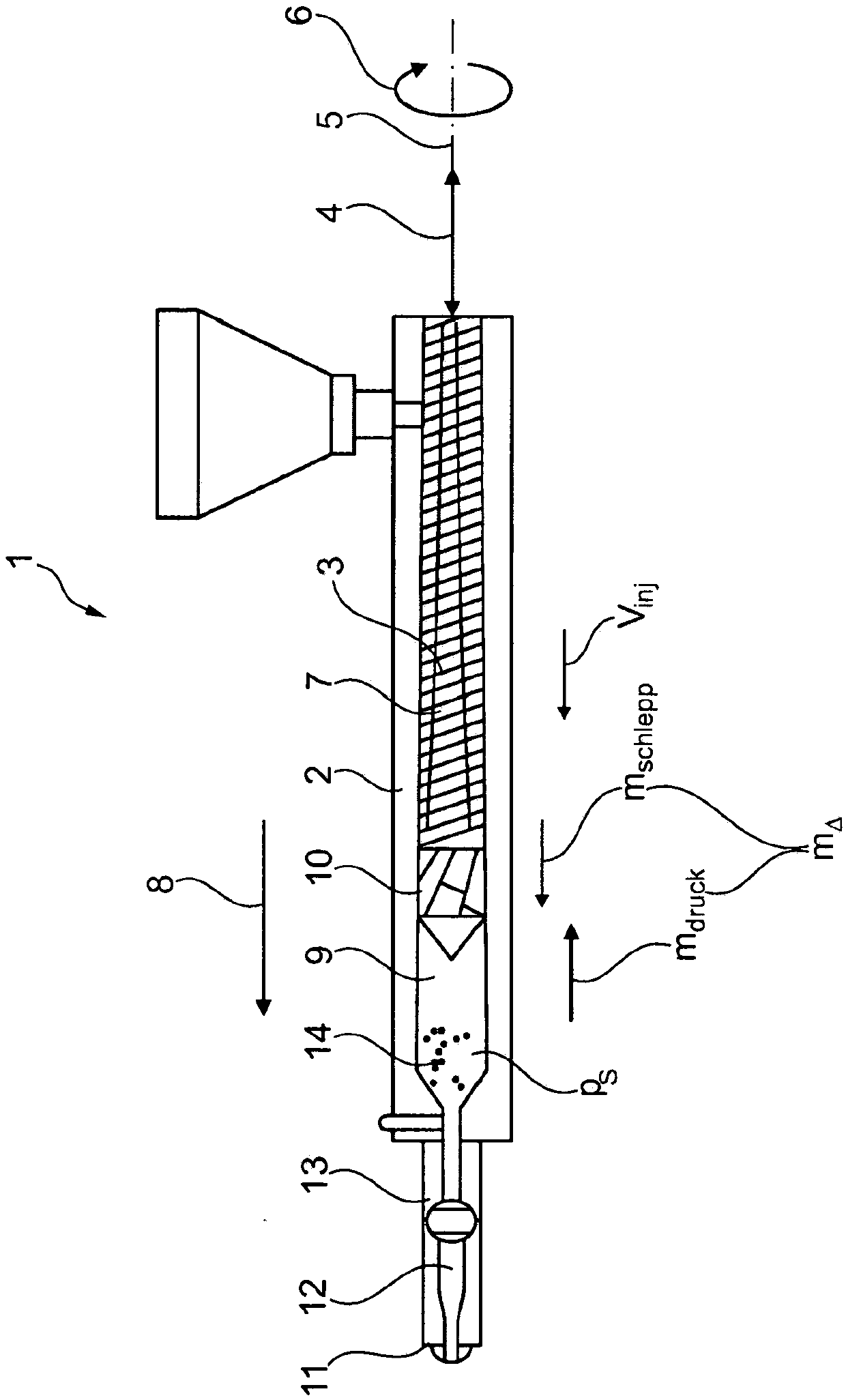

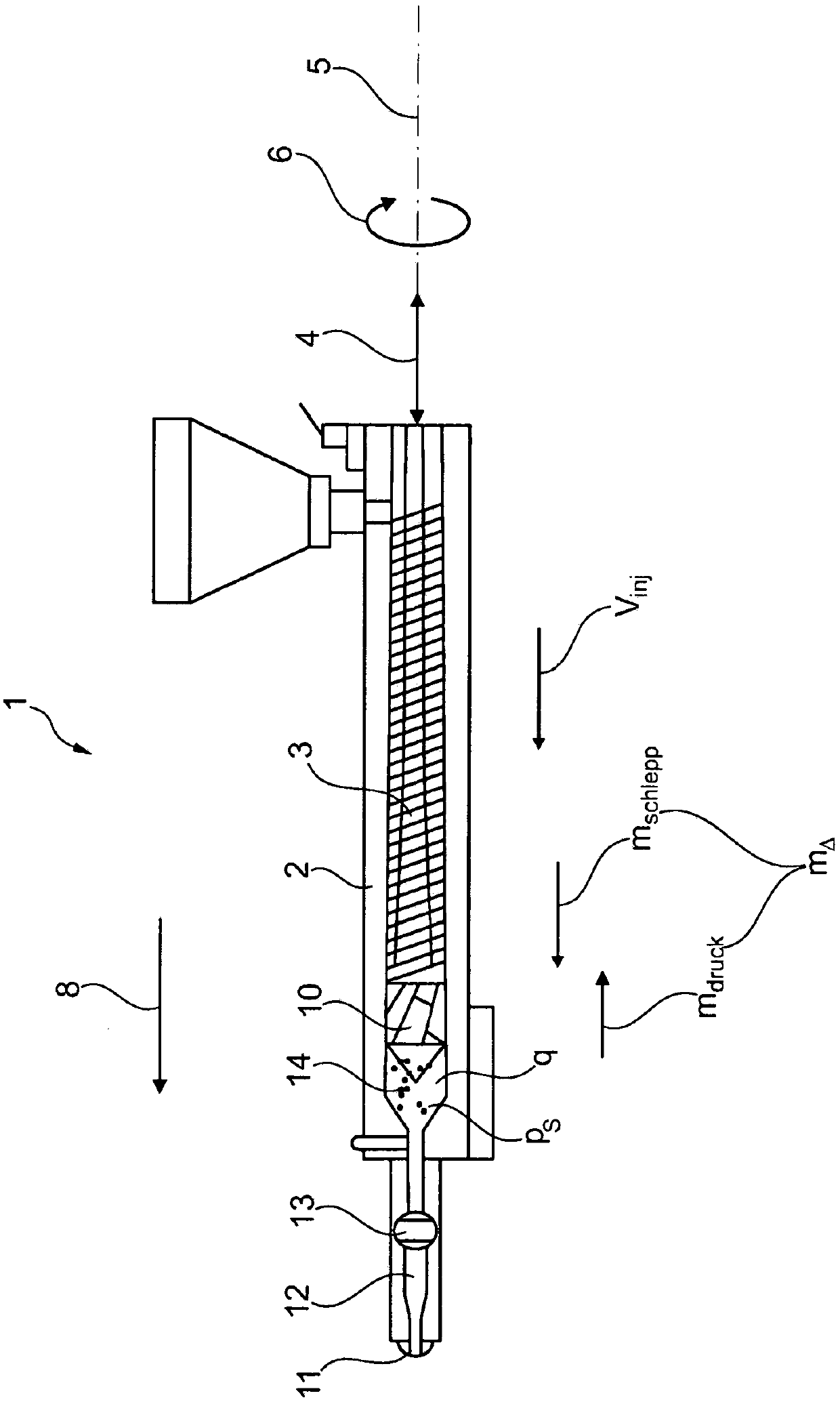

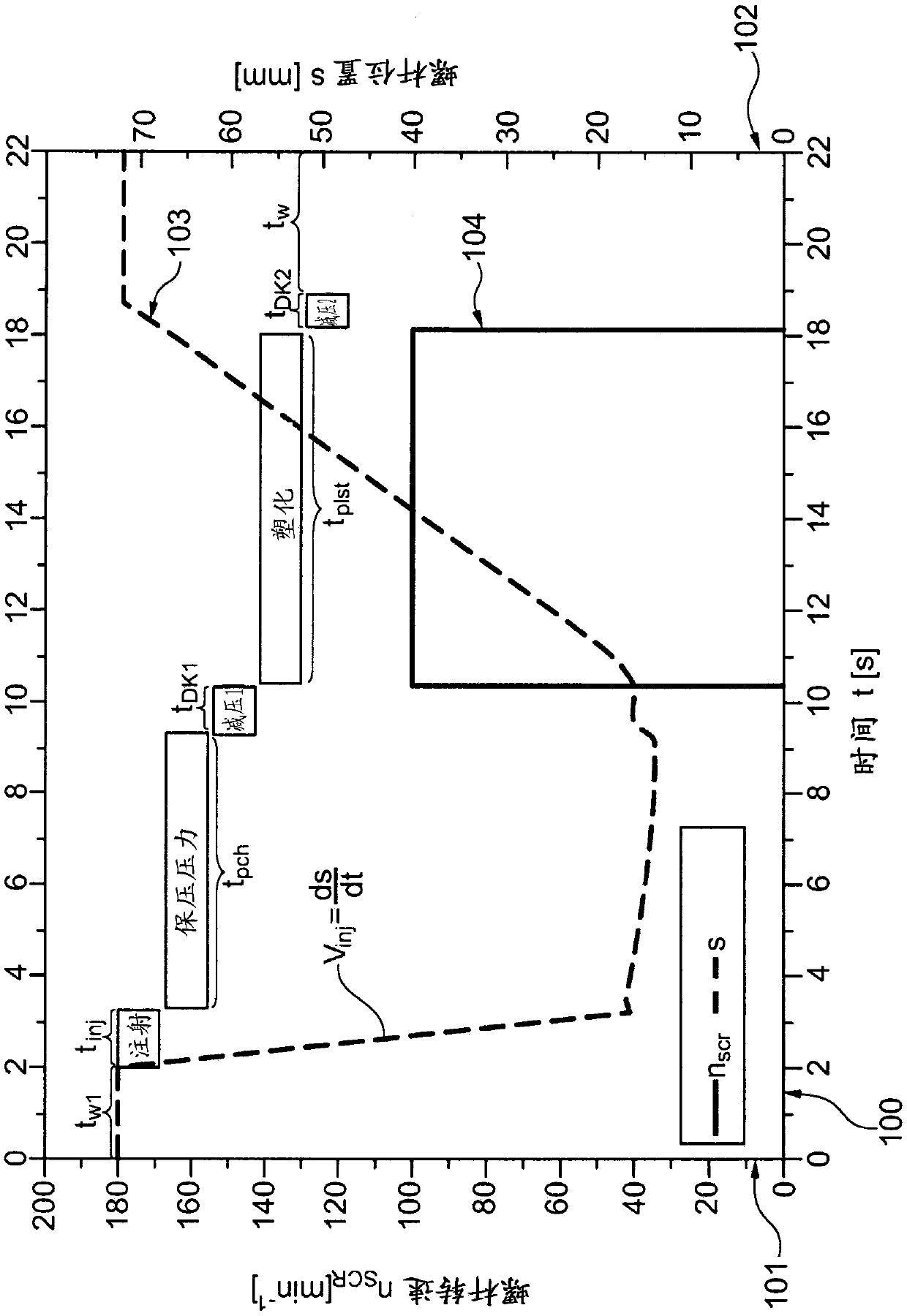

[0088] An injection molding machine 1 (injection molding machine) to which the method according to the invention can be applied has a plasticizing cylinder 2 in which a plasticizing screw 3 is arranged in a known manner. The plasticizing screw 3 can be translated in translation by means of a first drive (not shown) at a feed rate v inj Move in reciprocating direction 4. The plasticizing screw 3 can be rotated at a rotational speed n around its longitudinal axis 5 in the direction of rotation 6 by means of a second drive (not shown). scr actively driven. Through the rotational drive in the direction of rotation 6 , the plastic material within the screw flight 7 is conveyed in the conveying direction 8 to the screw antechamber 9 . The plasticizing screw 3 has a screw head 10 at its end facing the screw antechamber 9 . Backflow lockout is not set. The plasticizing cylinder 2 has an injection nozzle 11 on the end side, which is connected via a channel 12 to the screw antechamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com