Negative electrode for lithium secondary battery and lithium secondary battery comprising the same

一种锂二次电池、负极的技术,应用在锂二次电池领域,能够解决寿命特性降低、Si与粘合剂弱亲和力、劣化电极粘附力等问题,达到改善寿命特性、优异粘附力、改善输出特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

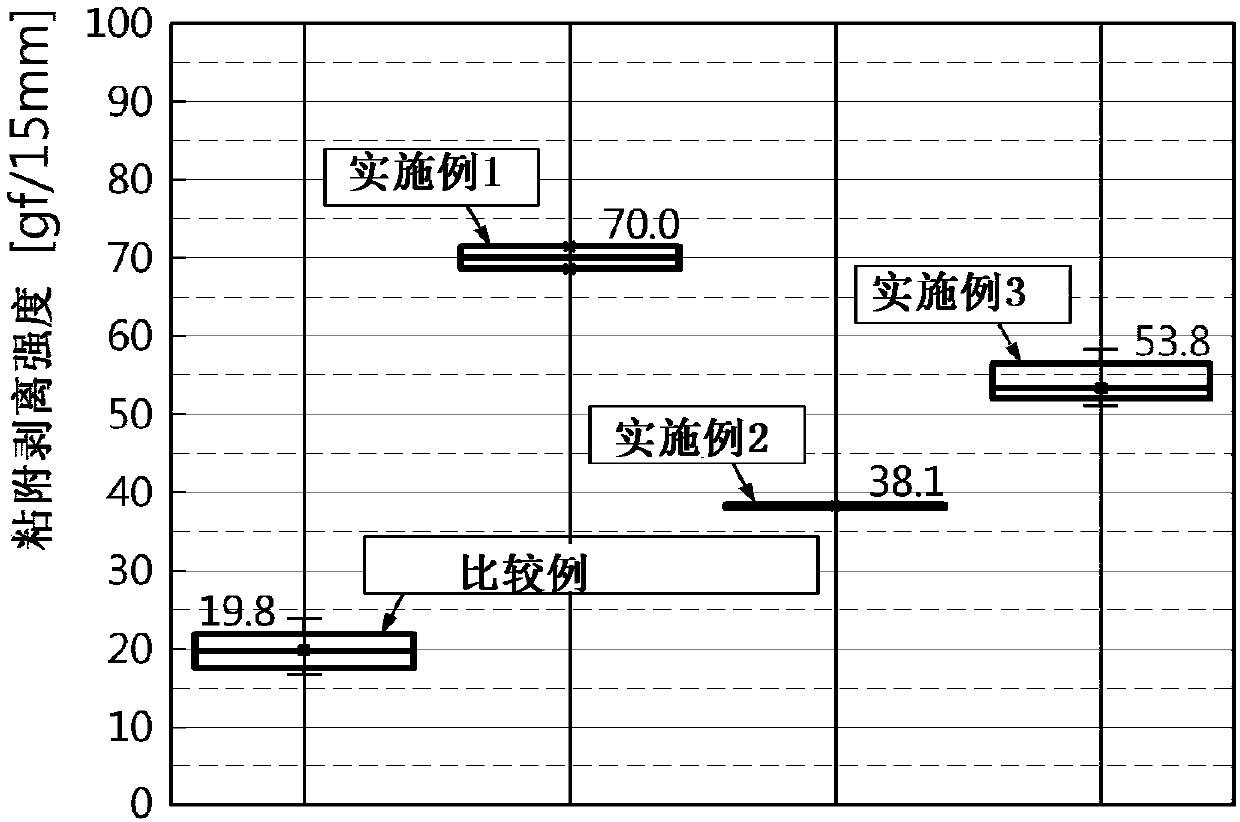

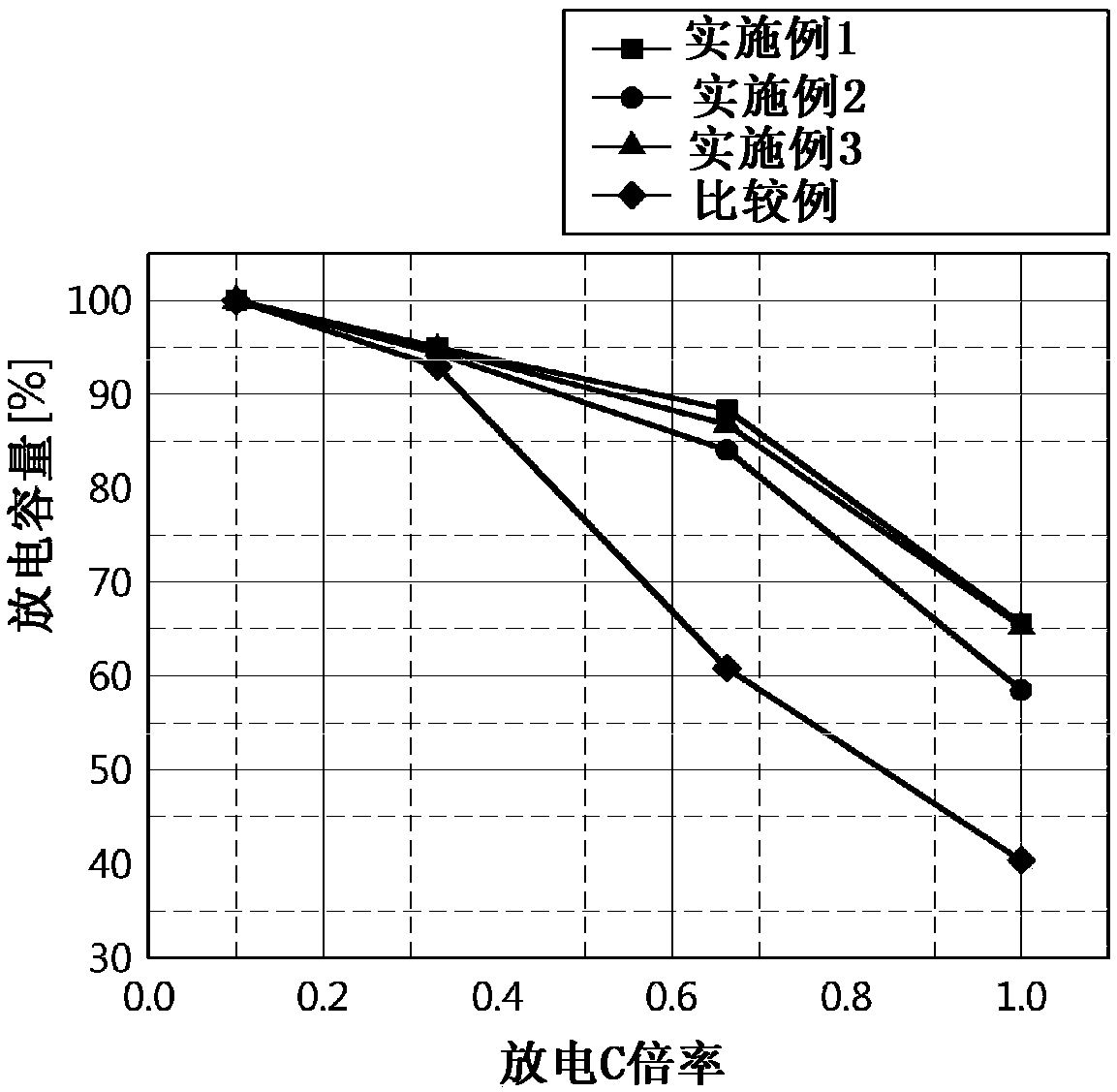

[0051] Mix 89.8% by weight of natural graphite, 4.7% by weight of SiO, 1.5% by weight of carbon black, 3% by weight of SBR binder and 1% by weight of CMC to prepare the first negative electrode slurry, and mix 94.5% by weight of artificial Graphite (coal tar pitch), 1.5% by weight of carbon black, 3% by weight of SBR binder and 1% by weight of CMC were used to prepare the second negative electrode slurry.

[0052] The first negative electrode slurry is 149mg / 25cm 2 The loading amount is coated on the copper foil, and the second negative electrode slurry is 345mg / 25cm 2 The loading amount of the first negative electrode slurry was coated on the upper surface of the first negative electrode slurry, and then they were dried in a vacuum oven at 100° C. for 10 hours or more. Then, an anode composed of a first anode mixture layer having a thickness of 48.1 μm and a second anode mixture layer having a thickness of 111.5 μm (a total thickness of 159.6 μm) was fabricated using a roll ...

Embodiment 2

[0056] Mix 85.1% by weight of natural graphite, 9.4% by weight of SiO, 1.5% by weight of carbon black, 3% by weight of SBR binder and 1% by weight of CMC to prepare the first negative electrode slurry, and mix 94.5% by weight of artificial Graphite (coal tar pitch), 1.5% by weight of carbon black, 3% by weight of SBR binder and 1% by weight of CMC were used to prepare the second negative electrode slurry.

[0057] The first negative electrode slurry is 150mg / 25cm 2 The loading amount is coated on the copper foil, and the second negative electrode slurry is 347mg / 25cm 2 The loading amount of the first negative electrode slurry was coated on the upper surface of the first negative electrode slurry, and then they were dried in a vacuum oven at 100° C. for 10 hours or more. Then, an anode composed of a first anode mixture layer having a thickness of 47.1 μm and a second anode mixture layer having a thickness of 109.1 μm (a total thickness of 156.2 μm) was fabricated using a roll ...

Embodiment 3

[0059] Mix 89.8% by weight of natural graphite, 4.7% by weight of SiO, 1.5% by weight of carbon black, 3% by weight of SBR binder and 1% by weight of CMC to prepare the first negative electrode slurry, and mix 94.5% by weight of artificial Graphite (coal tar pitch), 1.5% by weight of carbon black, 3% by weight of SBR binder and 1% by weight of CMC were used to prepare the second negative electrode slurry.

[0060] Described first negative electrode slurry is with 50mg / 25cm 2 The loading amount is coated on the copper foil, and the second negative electrode slurry is 447mg / 25cm 2The loading amount of the first negative electrode slurry was coated on the upper surface of the first negative electrode slurry, and then they were dried in a vacuum oven at 100° C. for 10 hours or more. Then, an anode composed of a first anode mixture layer having a thickness of 16.1 μm and a second anode mixture layer having a thickness of 144.4 μm (a total thickness of 160.5 μm) was fabricated usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com