High-speed visual detection equipment of soft magnetic core

A visual inspection and magnetic core technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems such as the inability to meet the detection speed detection speed requirements, complex detection process, and low degree of automation. Achieve the effect of all-round high-speed inspection, advanced visual algorithm and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

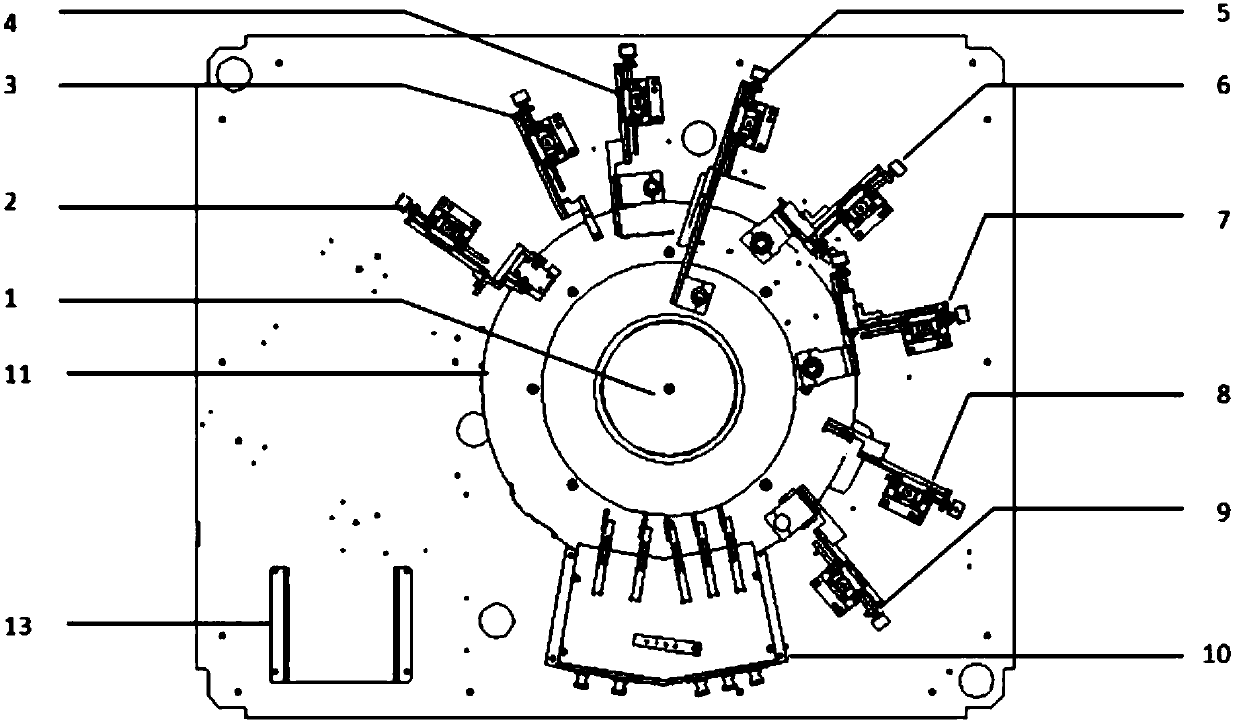

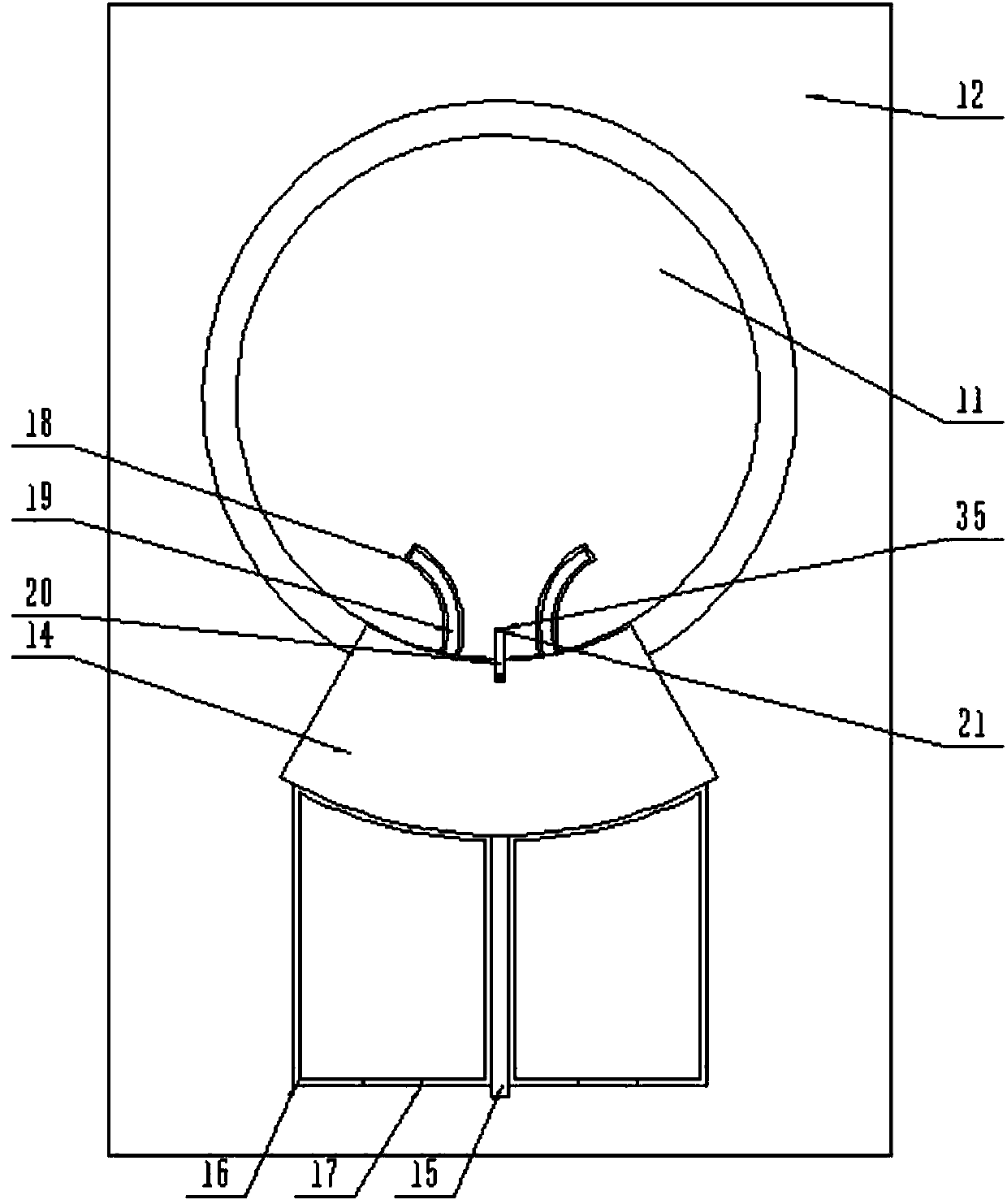

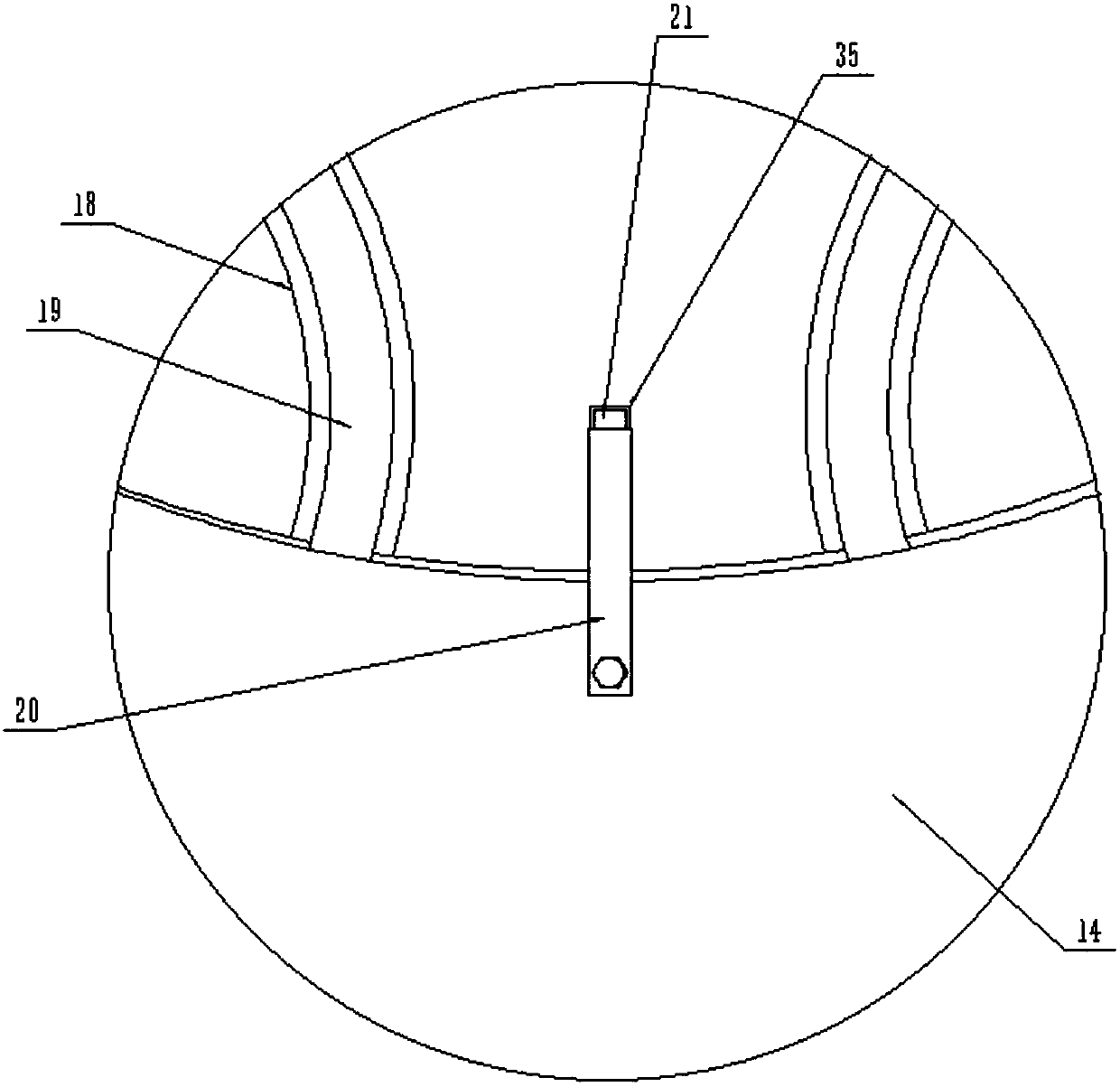

[0019] The present invention will be specifically described below in conjunction with the accompanying drawings, such as Figure 1-6 As shown in the figure, a high-speed visual inspection equipment for a soft magnetic core includes a device table (12), and the device table (12) is provided with a feeding turntable (11), a servo drive unit (1), and a workpiece posture adjustment module (2), photoelectric switch (3), front station CCD and light source module (4), rear station CCD and light source module (5), left station CCD and light source module (6), right station CCD and light source module (7), an upper station CCD and a light source module (8), a lower station CCD and a light source module (9) and an industrial computer (13), the feeding turntable (11) is arranged on the device table (12) through a rotating fixing mechanism ), the feeding turntable (11) is provided with a kicking module station (10), and the kicking module station (10) is fixed on the feeding turntable (11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com