Anti-loosening screw fastener connection structure

A technology for threaded fasteners and connection structures, which is applied in the direction of threaded fasteners, connecting components, locking fasteners, etc. It can solve problems that affect the use of equipment, simple nut structure, and potential safety hazards, so as to prevent loosening , Eliminate potential safety hazards and reduce the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

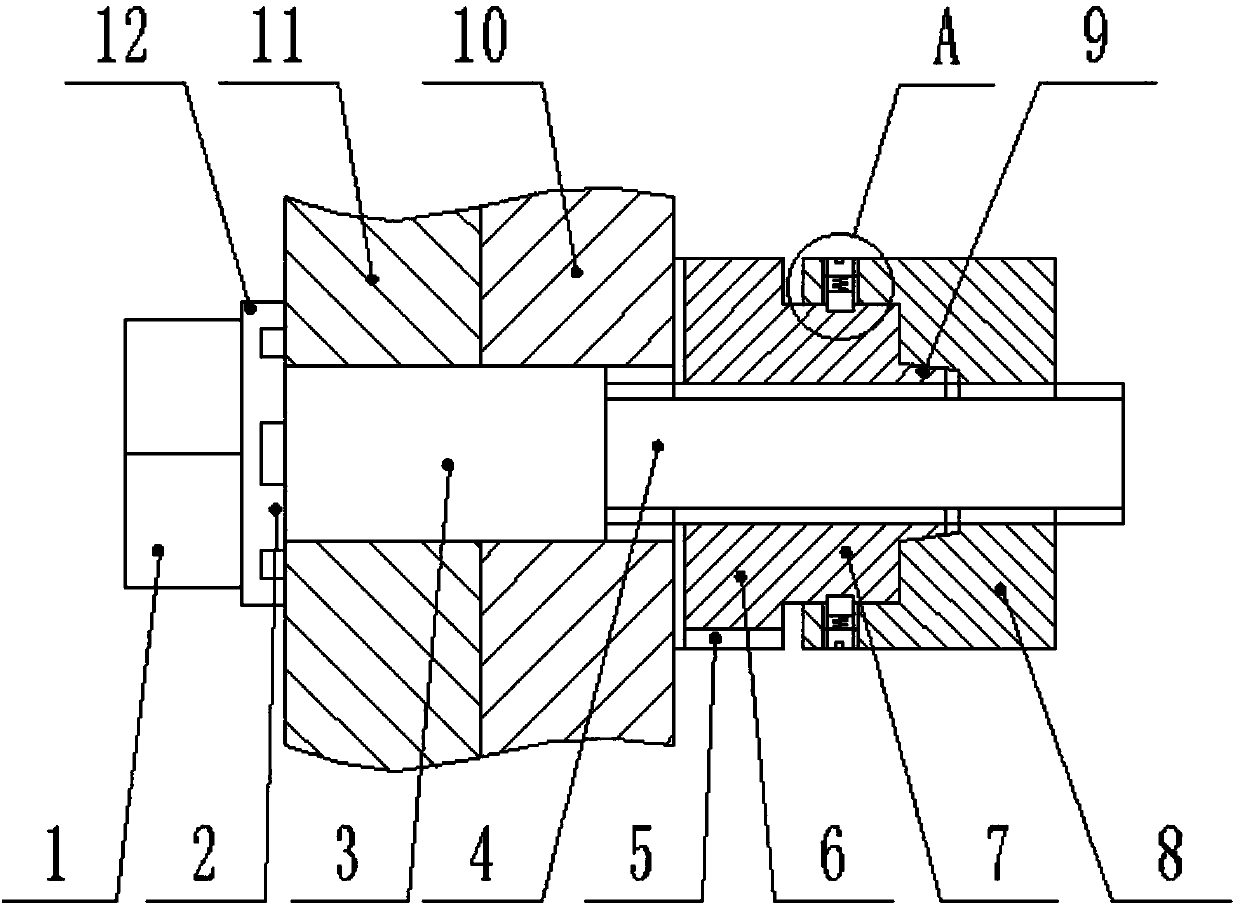

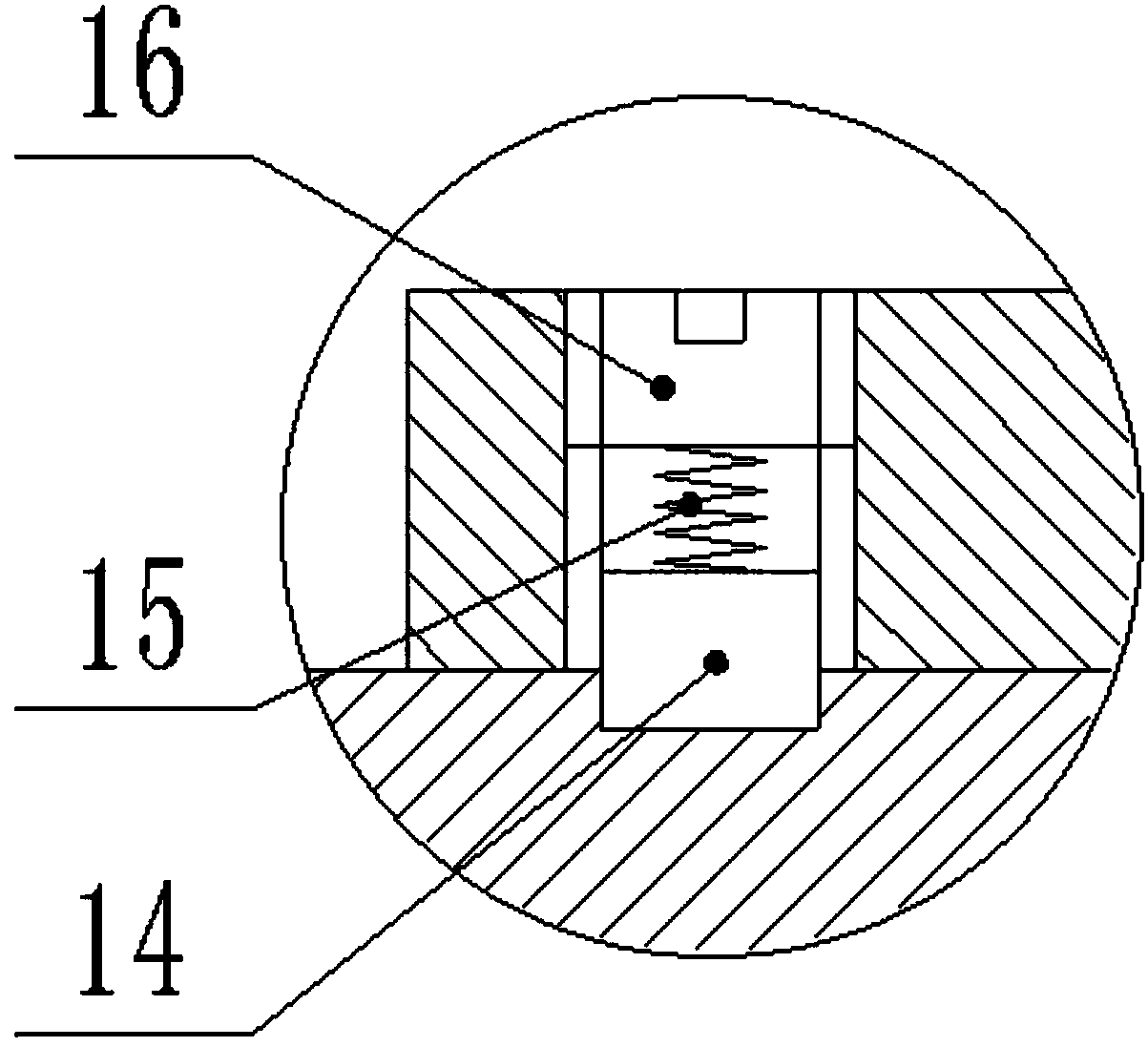

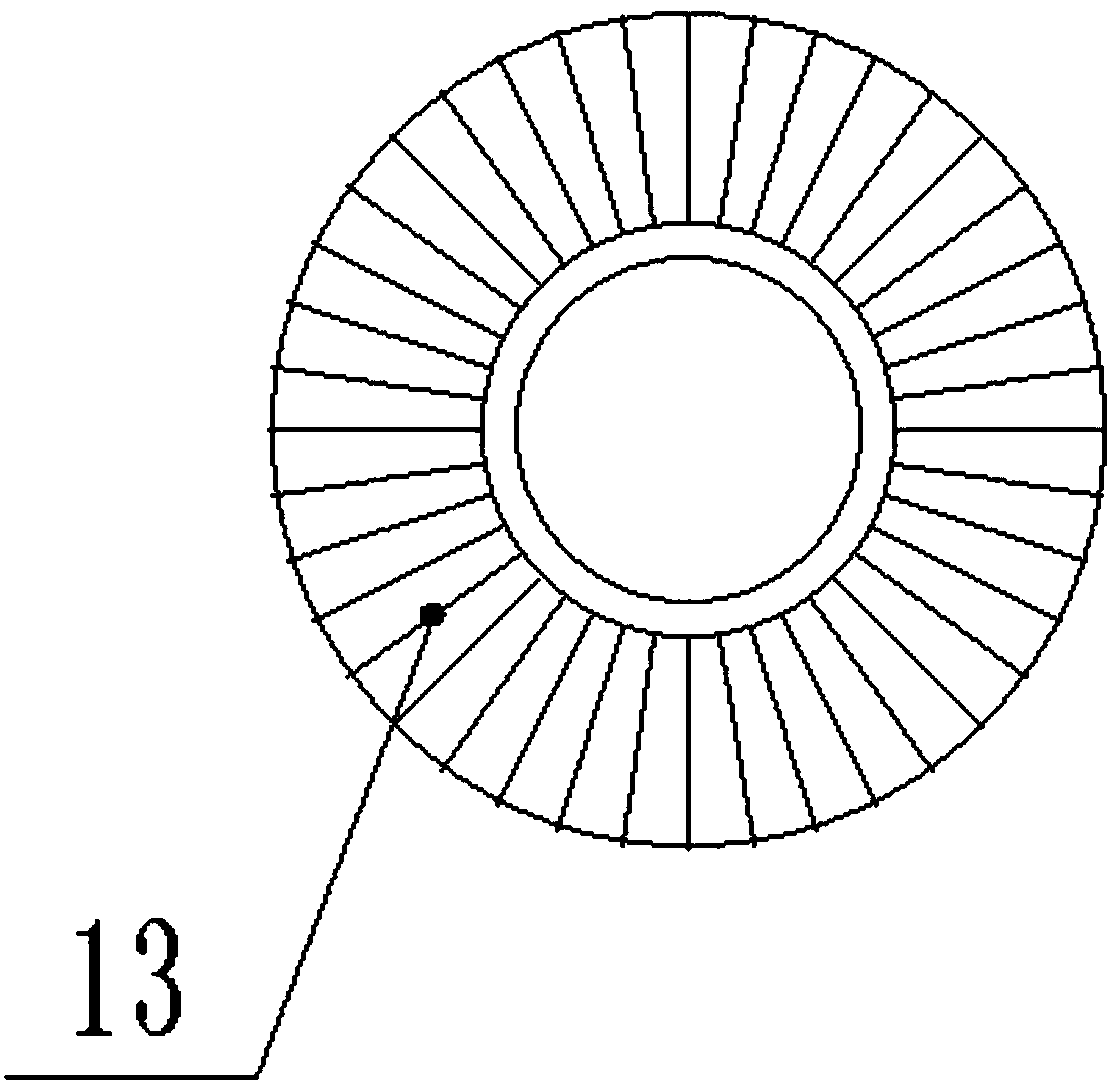

[0021] This embodiment includes a part A11, a part B10, a screw and a combined nut. The part A11 and the part B10 are connected through the cooperation of the screw and the combined nut. The screw includes a head 1, a positioning section 3 and a threaded section 4. The head 1 described above has a hexagonal prism structure, and the combined nut includes an inner nut and an outer nut 8, both of which are connected to the threaded section 4 of the screw rod through threads, wherein the inner nut is installed between the part B10 and the outer nut 8 In between, the inner nut and the outer nut 8 are respectively provided with conical bosses 9 and grooves that cooperate with each other, wherein the bosses 9 are concentrically arranged with the screw rod, and the grooves are eccentrically arranged with the bosses 9, and the eccentricity is the boss 9 1 / 20 of the middle diameter, the inner nut includes a hexagonal prism section 6 and a cylindrical section 7, the cylindrical section 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com