Low-VOC (Volatile Organic Compounds) and low-odor waterborne wood coating and preparation method thereof

A wood coating and low-odor technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of high VOC, achieve the effect of improving crosslinking degree, improving toughness and adhesion, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

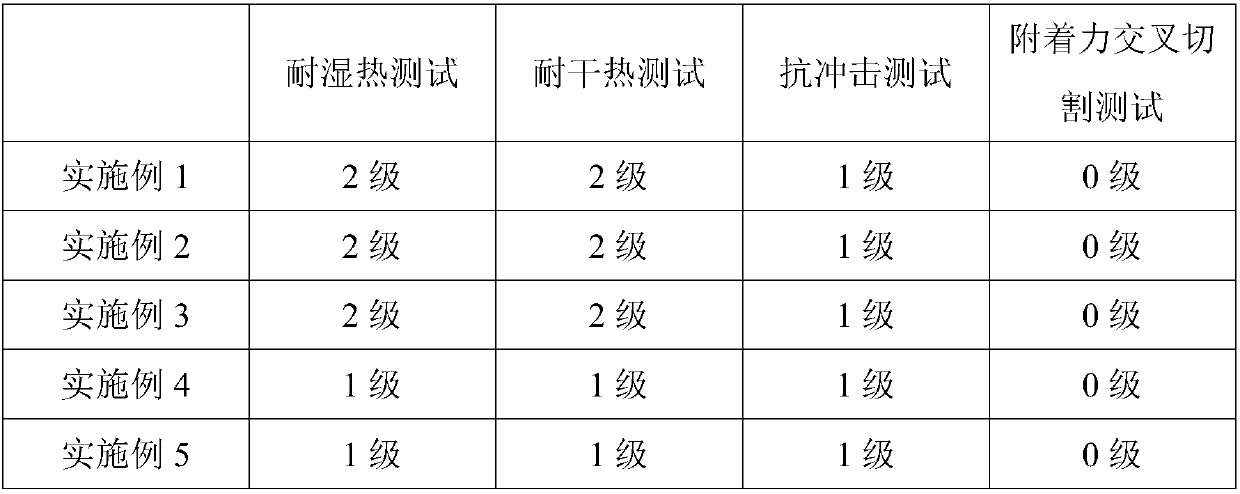

Examples

Embodiment 1

[0026] A low-VOC and low-odor water-based wood coating, consisting of the following parts by weight: 70 parts by weight of polytetrahydrofuran diol, 70 parts by weight of lysine diisocyanate, 90 parts by weight of acrylic resin (molecular weight: 100000, solid content: 60%), 6 parts by weight of triethylbenzyl ammonium chloride, 5 parts by weight of graphene oxide, 8 parts by weight of starch, 10 parts by weight of castor oil, 5 parts by weight of polyoxyethylene sorbitan monooleate, polydimethylsiloxane 3 parts by weight of oxane, 4 parts by weight of carboxymethyl cellulose, 3 parts by weight of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 2 parts by weight of n-octylisothiazolinone .

[0027] The preparation method of described low-VOC low-odor water-based wood coating, comprises the following steps:

[0028] 1. Mix graphene oxide, dimethylformamide, n-hexane and dicyclohexyl carboximide, ultrasonically treat for 15 minutes, then react at 120°C for 50 hours, add absolu...

Embodiment 2

[0031] A low-VOC and low-odor water-based wood coating, comprising the following parts by weight: 75 parts by weight of tetrahydrofuran-propylene oxide copolymerized glycol, 75 parts by weight of toluene diisocyanate, 80 parts by weight of acrylic resin (molecular weight 90000, solid content is 65%) , 6 parts by weight of triethylbenzyl ammonium bromide, 3 parts by weight of graphene oxide, 10 parts by weight of starch, 8 parts by weight of castor oil, 8 parts by weight of polyoxyethylene sorbitan monooleate, HR polyether disinfectant 2 parts by weight of foaming agent, 5 parts by weight of carboxymethyl cellulose, 3 parts by weight of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, and 1 part by weight of aryl urea derivative.

[0032] The preparation method of described low-VOC low-odor water-based wood coating, comprises the following steps:

[0033] 1. Mix graphene oxide, dimethylformamide, n-hexane and dicyclohexylcarboimide, ultrasonically treat it for 15 minutes, then ...

Embodiment 3

[0036] A low-VOC and low-odor water-based wood coating, consisting of the following parts by weight: 60 parts by weight of tetrahydrofuran-propylene oxide copolymerized glycol, 75 parts by weight of isophorone diisocyanate, 95 parts by weight of acrylic resin (molecular weight 80000, solid content of 55%), 5 parts by weight of triethylbenzyl ammonium chloride, 8 parts by weight of graphene oxide, 5 parts by weight of starch, 12 parts by weight of castor oil, 3 parts by weight of polyoxyethylene sorbitan monooleate, 3 parts by weight of glycol siloxane, 3 parts by weight of hydroxyethyl cellulose, 4 parts by weight of tripropylene glycol n-butyl ether, and 3 parts by weight of imidazole derivatives.

[0037] The preparation method of described low-VOC low-odor water-based wood coating, comprises the following steps:

[0038] 1. Mix graphene oxide, dimethylformamide, n-hexane and dicyclohexyl carboximide, ultrasonically treat for 15 minutes, then react at 150°C for 40 hours, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com