Multifunctional heat-preservation diatom ooze for interior wall and preparation method thereof

A diatom mud, multi-functional technology, applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of insufficient use of diatom mud, uneven quality, single function, etc., to achieve excellent reactivity, Good color matching and good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

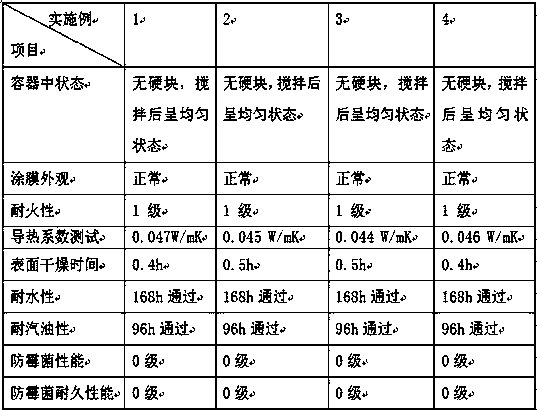

Examples

Embodiment 1

[0074] The preparation method of multi-functional inner wall thermal insulation diatom mud, which includes the following raw materials in parts by weight: 60 parts of diatomite, 10 parts of inorganic expansion vitrified light insulation material, 15 parts of epoxy resin, 3 parts of composite coupling agent , 15 parts of pearl powder, 7 parts of sepiolite, 5 parts of sericite powder, 2 parts of defoamer, 1 part of thickener, 2 parts of dispersant, 2 parts of wetting agent AP-680, 45 parts of water;

[0075] The preparation process of multifunctional interior wall insulation diatom mud includes the following steps:

[0076] (1) Add pearlescent powder in parts by weight, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water in the mixer, mix and stir, stir evenly, and the speed is 300 rpm, stirring for 10 minutes;

[0077] (2), add inorganic expansion vitrified light insulation material, sepiolite, sericite powder to step (1), mix and stir, stir evenly, the speed ...

Embodiment 2

[0082] The preparation method of multi-functional inner wall thermal insulation diatom mud, which includes the following raw materials in parts by weight: 70 parts of diatomite, 15 parts of inorganic expansion vitrified light insulation material, 20 parts of epoxy resin, 4 parts of composite coupling agent , 17 parts of pearl powder, 10 parts of sepiolite, 7 parts of sericite powder, 3 parts of defoamer, 2 parts of thickener, 3 parts of dispersant, 2 parts of wetting agent AP-680, 50 parts of water;

[0083] The preparation process of multifunctional interior wall insulation diatom mud includes the following steps:

[0084] (1) Add pearlescent powder in parts by weight, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water in the mixer, mix and stir, stir evenly, and the speed is 300 rpm, stirring for 15 minutes;

[0085] (2) Add inorganic expansion vitrified lightweight thermal insulation material, sepiolite, and sericite powder to step (1), mix and stir, stir...

Embodiment 3

[0090] The preparation method of multi-functional inner wall thermal insulation diatom mud, which includes the following raw materials in parts by weight: 80 parts of diatomite, 20 parts of inorganic expansion vitrified light insulation material, 25 parts of epoxy resin, 5 parts of composite coupling agent , 18 parts of pearl powder, 12 parts of sepiolite, 8 parts of sericite powder, 3 parts of defoamer, 3 parts of thickener, 4 parts of dispersant, 2 parts of wetting agent AP-680, 55 parts of water;

[0091] The preparation process of multifunctional interior wall insulation diatom mud includes the following steps:

[0092] (1) Add pearlescent powder in parts by weight, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water in the mixer, mix and stir, stir evenly, and the speed is 300 rpm, stirring for 12 minutes;

[0093] (2), add inorganic expansion vitrified light insulation material, sepiolite, sericite powder to step (1), mix and stir, stir evenly, the spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com