Porous water absorbing material

一种孔吸水、聚乳酸的技术,应用在材料领域,能够解决精液破坏、影响受精率等问题,达到降低自然挥发、保证采集质量、保证效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

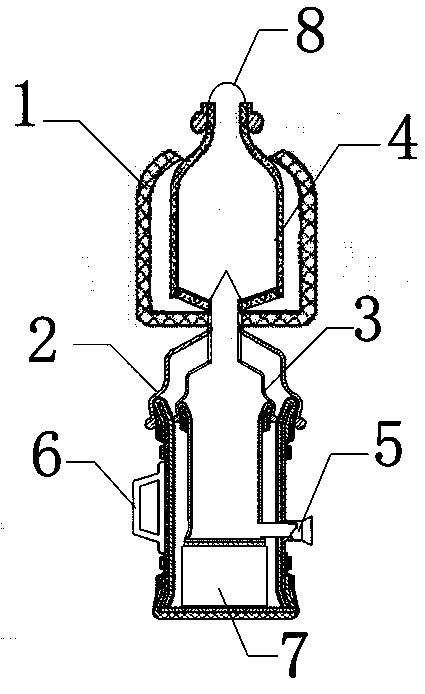

[0036] Such as figure 1 Shown, a kind of laying hen semen collection cup, comprises the second fine chamber 2 that is flexibly connected with the first fine chamber 1, and the bottom of the first fine chamber 1 is connected with the top of the second fine chamber 2, and the first fine chamber 1 is Double-layer structure, the first fine chamber 1 is provided with an inner chamber 4, the inner chamber 4 is separated from the outer wall of the first fine chamber, the inner chamber 4 communicates with the second fine chamber, the bottom of the inner chamber 4 is inclined to the middle, and the bottom of the inner chamber 4 The middle part is provided with a protrusion, and the diameter of the bottom surface of the protrusion is equal to the diameter of the communication channel between the inner chamber 4 and the second fine chamber. The inner chamber 4 is made of porous water-absorbing material, and there is a diluent between the inner chamber 4 and the first fine chamber 1 . Th...

Embodiment 2

[0040] The crotonate grafted chitosan was prepared by the following steps,

[0041] Step 1: Take a portion of chitosan, take an appropriate amount of water as a solvent, adjust the pH of the solution to 4.7, add an appropriate amount of isopropanol to prepare a suspension with a starch mass fraction of 37%, and stir for 30 minutes;

[0042]Step 2: Add NaOH to the solution according to the chitosan:NaOH mass ratio of 1:0.05, heat up to 30°C, stir at a constant temperature for 30 minutes, and slowly add allyl dropwise to the solution according to the NaOH:allyl chloride molar ratio of 1:1.2 base chloride, warming up to 50°C, stirring at constant temperature for 24h;

[0043] Step 3: filter, take the solid and redisperse it in a distilled water-ethanol solution with a volume ratio of 18:82, adjust the pH to 7 with acetic acid, wash with an appropriate amount of distilled water after suction filtration, and dry to obtain allyl etherified chitosan;

[0044] Step 4: Take a portion ...

Embodiment 3

[0047] Nano-hydroxy calcium phosphate / polycaprolactone / polylactic acid is prepared by the following method: through the reaction formula Ca(NO 3 )·4H 2 O+(NH 4 ) 2 HPO 4 → Ca 10 (PO 4 ) 6 (OH) 2 To prepare nano-calcium hydroxyphosphate, configure nano-calcium hydroxyphosphate into a slurry with a mass fraction of 5%, add the slurry to a three-necked bottle with a water separator, a stirring device and a condensation device, and add 150mL solvent DMAC and an appropriate amount of polyethylene glycol at the same time. For diol, the temperature is gradually increased to 100°C, dehydrated at 100-120°C, then polycaprolactone and polylactic acid are added in proportion, stirred and compounded for 4 hours at 120-130°C, taken out, and washed with hot deionized water for 4 hours times, washed with ethanol twice, and dried at 50-60°C for 48 hours to obtain a composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com