Road or bridge deck pavement durable sealing layer and preparation method thereof

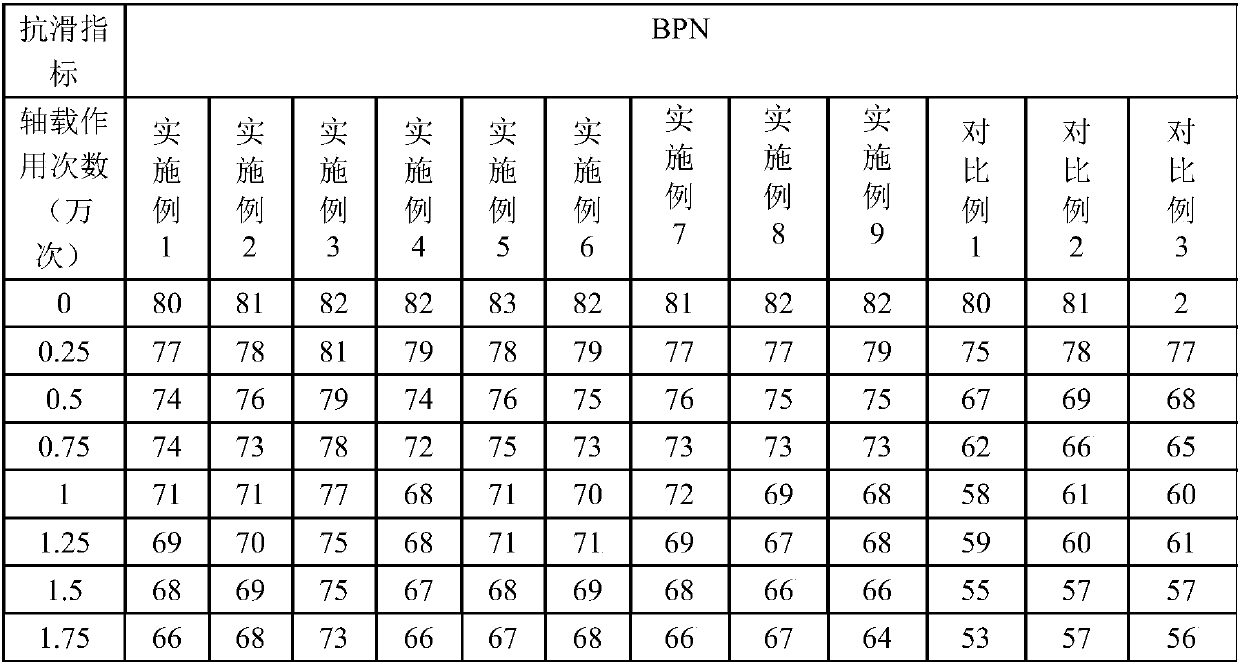

A bridge deck pavement and durable technology, which is applied to road or bridge deck pavement durable seal layer and its preparation, road or bridge deck pavement durable seal layer field, can solve the bonding performance between base layer and asphalt surface layer, Crack resistance and poor waterproof performance, to achieve the effect of improving initial slip resistance, strong impact resistance and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

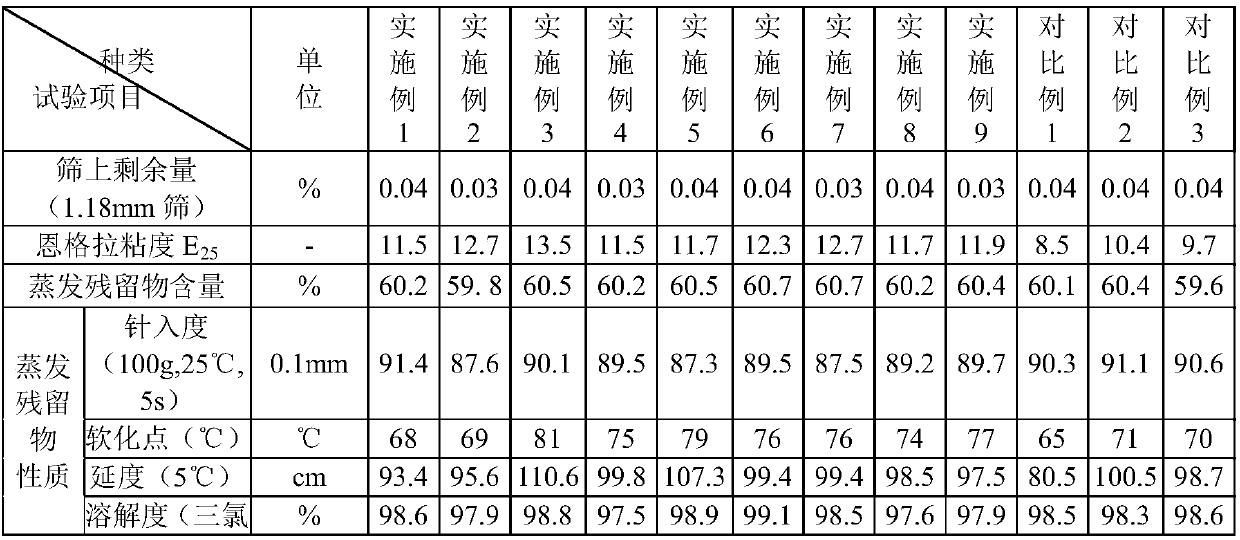

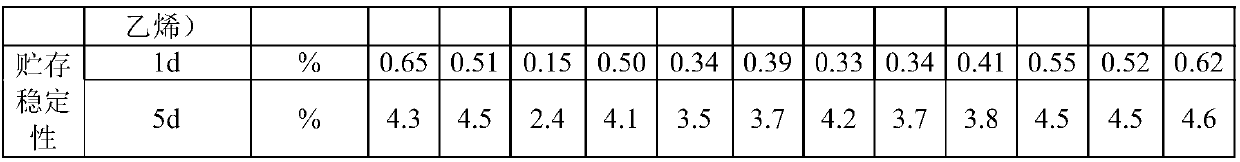

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned durable sealing layer for road or bridge deck pavement specifically includes the following steps:

[0036] Step 1: Cut the waste ultra-high molecular weight polyethylene sheet into 10cm and boil it in 0.4% sodium carbonate boiling water solution for 30min. After washing and drying, extract with acetone in a Soxhlet extractor for 24h to remove After surface organic attachment, dry to constant weight in oven;

[0037] Step 2, soak the ultra-high molecular weight polyethylene sheet obtained in the above step 1 in a solution containing 0.5% V-50 initiator, under 400W microwave conditions, rise from room temperature to 80°C for 20 minutes at a constant temperature, and then pass through it once Padding (0.3MPa, 1m / min) to remove the initiator remaining on the surface, transfer the ultra-high molecular weight polyethylene sheet with the initiator to the aqueous solution containing water-based polyurethane monomer, and carry out th...

Embodiment 1

[0046] The present embodiment provides a durable sealing layer for road or bridge deck pavement, which is made of the following raw materials in parts by weight: 100 parts of mineral material, 15 parts of grafted ultra-high molecular weight polyethylene-waterborne polyurethane, emulsified 25 parts of asphalt, the grafted ultra-high molecular weight polyethylene-water-based polyurethane in the present embodiment, in parts by weight, is made of the following raw materials: 100 parts of ultra-high molecular weight polyethylene, 10 parts of water-based polyurethane, 3 parts of initiator . The emulsified asphalt in this embodiment is made of the following raw materials in parts by weight: 55 parts of asphalt, 2 parts of emulsifier, 3 parts of stabilizer, and 100 parts of water. A method for preparing a durable sealing layer for road or bridge deck pavement, specifically comprising the following steps:

[0047] Step 1: Cut the waste ultra-high molecular weight polyethylene sheet in...

Embodiment 2

[0055] The present embodiment provides a durable sealing layer suitable for road or bridge deck pavement, which is made of the following raw materials in parts by weight: 100 parts of mineral material, 15 parts of grafted ultra-high molecular weight polyethylene-waterborne polyurethane , 25 parts of emulsified asphalt, the grafted ultra-high molecular weight polyethylene-water-based polyurethane in the present embodiment, in parts by weight, is made of the following raw materials: 100 parts of ultra-high molecular weight polyethylene, 15 parts of water-based polyurethane, initiator 3 copies. The emulsified asphalt in this embodiment is made of the following raw materials in parts by weight: 55 parts of asphalt, 2 parts of emulsifier, 3 parts of stabilizer, and 100 parts of water. A method for preparing a durable sealing layer for road or bridge deck pavement, specifically comprising the following steps:

[0056] Step 1: Cut the waste ultra-high molecular weight polyethylene s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com