Coating barrel used for being filled with high-grade coating

A technology of paint buckets and paints, which is applied in packaging, transportation and packaging, rigid containers, etc., and can solve problems such as property damage, physical health injuries, and pits on the outer surface of paint buckets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

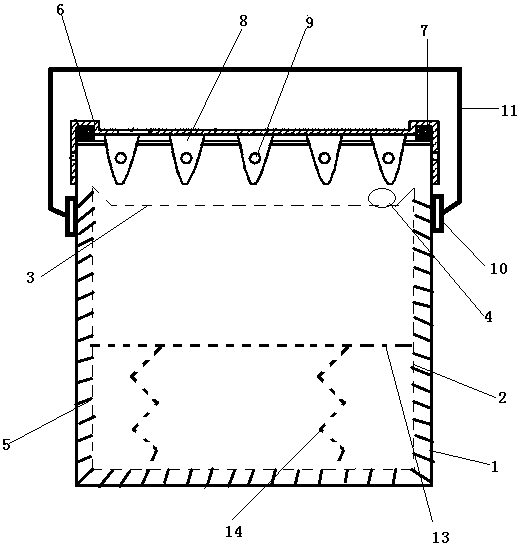

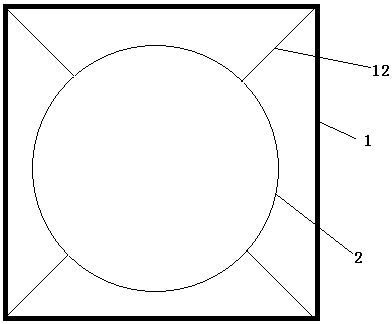

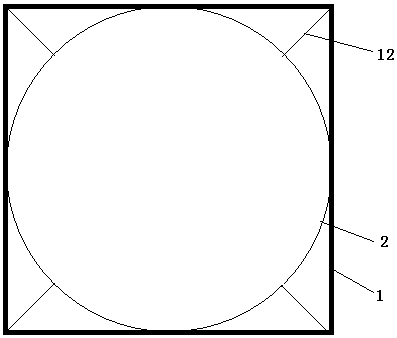

[0022] Example: such as figure 1 As shown, a paint barrel for filling high-grade paint includes an outer barrel body 1 and an inner barrel body 2, the inner barrel body 2 is arranged in the outer barrel body 1, and the outer barrel body 1 adopts a cuboid structure, The cross-section of the outer barrel body 1 is a square, the inner barrel body 2 adopts a cylindrical structure, the back side of the outer barrel body cover 6 is provided with a sealing ring 7 connected to the outer layer barrel body 1, and the outer layer barrel body cover 6 is along the A triangular elastic fastening plate 8 is evenly connected to the edge direction. The elastic fastening plate 8 is provided with a pull hole structure 9. The top of the inner barrel body 2 adopts a groove design. The inner barrel body cover 3 and the inner barrel body 2 Surrounded by a clamshell design, the bottom of the inner barrel body 2 is provided with two hard springs as the lifting spring 14, and a circular lifting plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com