Packing structure

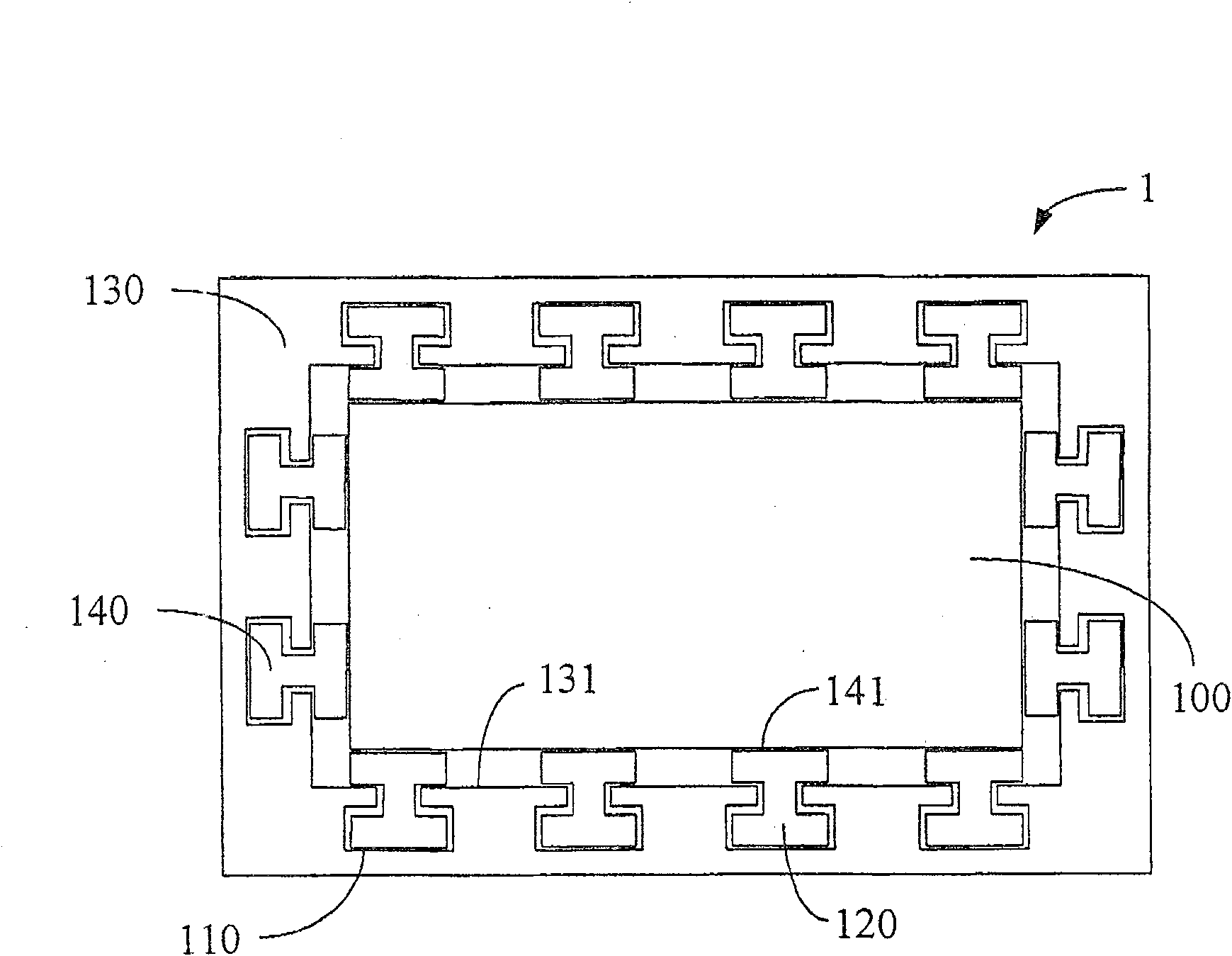

A packaging structure and hollow technology, which is applied in the field of packaging structure of plate-shaped objects, can solve the problems of inability to effectively absorb impact, inability to place smoothly, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

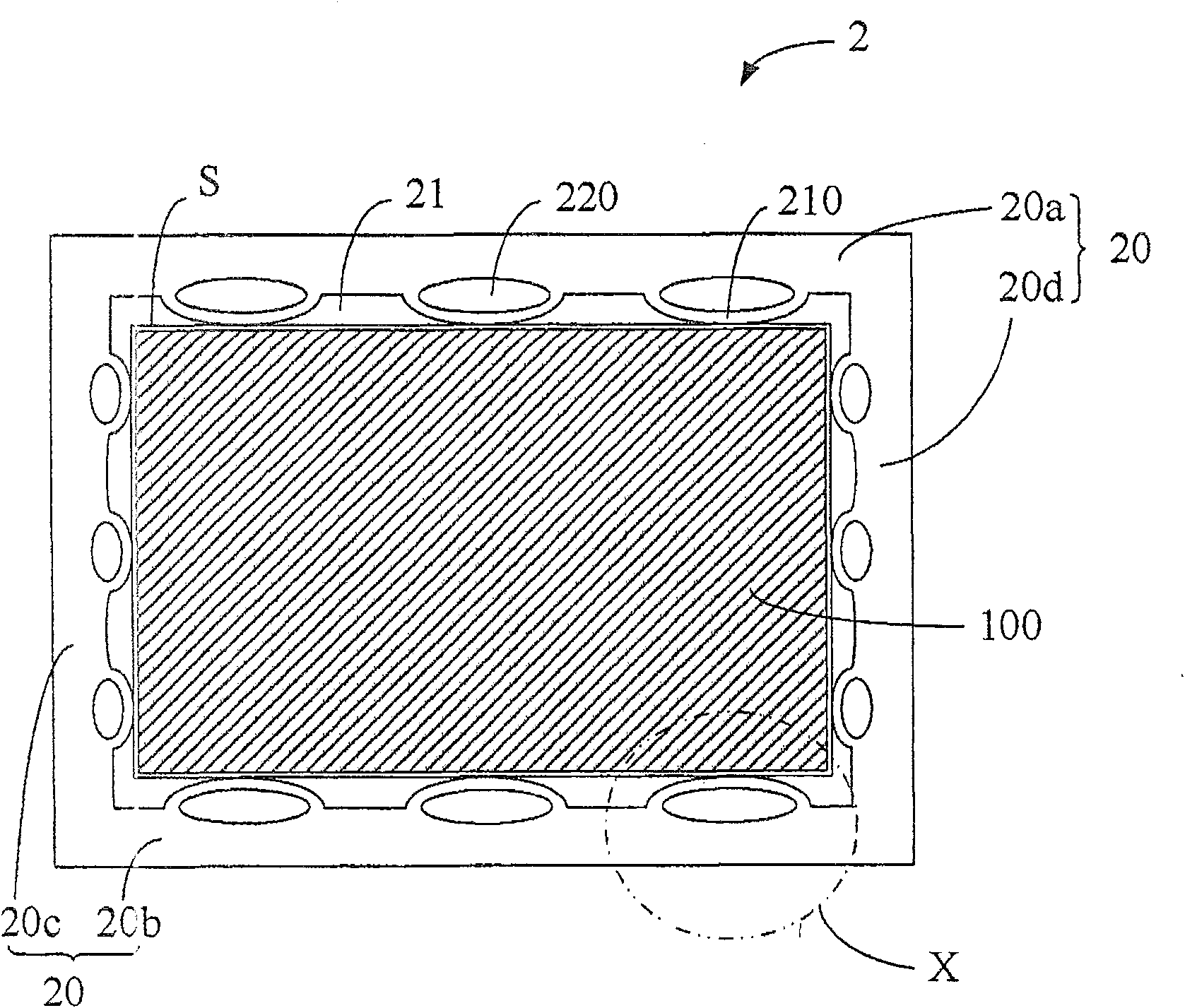

[0035] A kind of packaging structure 2 of the first embodiment of the present invention, its sectional view is as follows Figure 2A As shown, the packaging structure 2 is used to cushion a plate-shaped object 100 . In this embodiment, the plate-like object 100 preferably includes at least one glass substrate. The packaging structure 2 includes a base 21, four side walls 20a, 20b, 20c, 20d and a cover 60 (see Figure 2C shown). Four sidewalls 20 a , 20 b , 20 c , 20 d are respectively formed on four sides of the base 21 to define an accommodating space S together. In this embodiment, the accommodating space S is substantially a rectangular space. In other embodiments, those skilled in the art can easily deduce other numbers, positions and shapes of sidewalls.

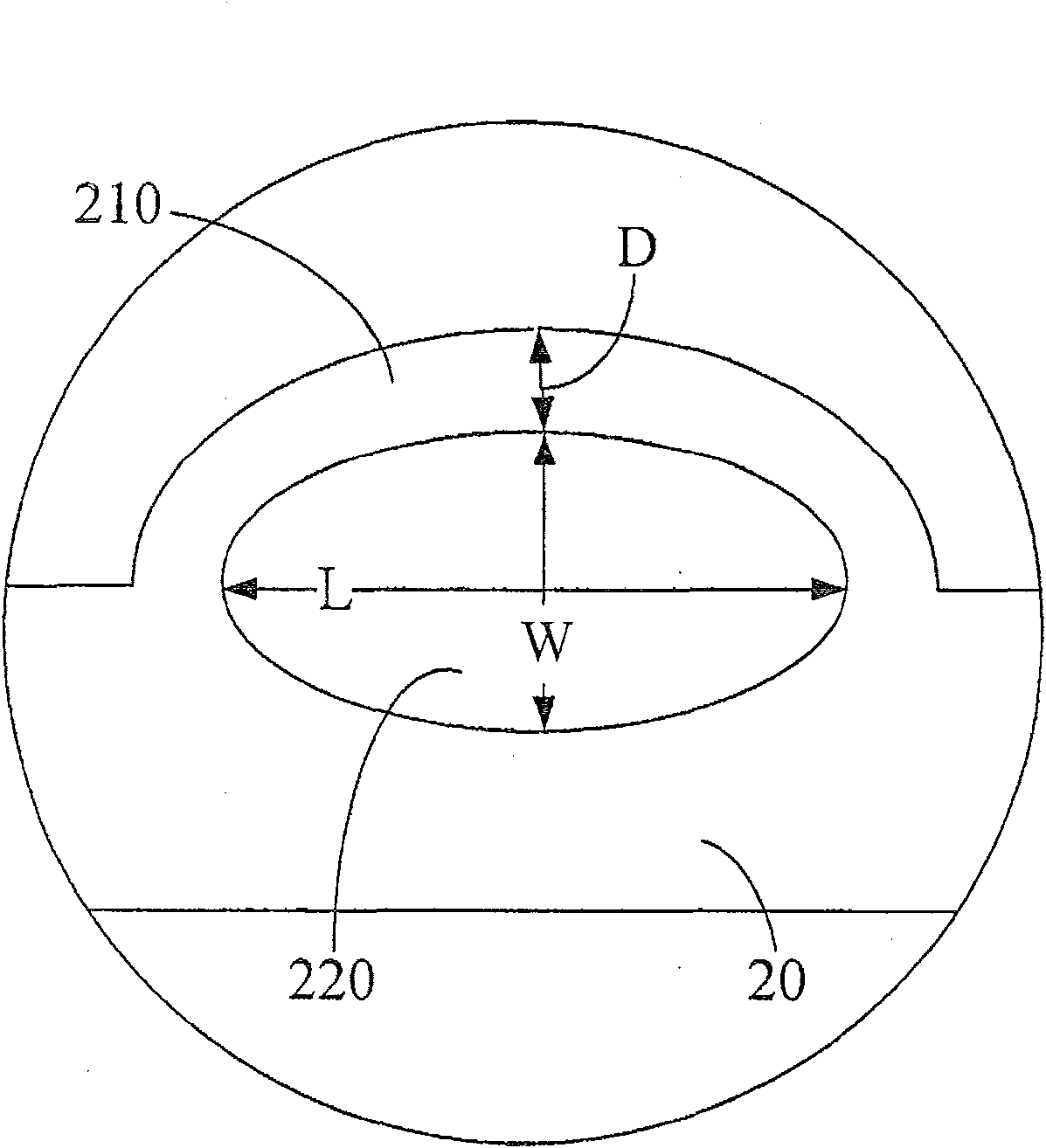

[0036] Inside the sidewalls 20a, 20b, 20c, and 20d, several hollow protrusion structures 210 are formed; these hollow protrusion structures 210 have a plurality of sequentially distributed hollow portions 220, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com