Automatic sealant pouring device for elements for production of power modules

A power module and potting glue technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem that the speed of glue filling can not be controlled very well, the influence of power electronic and mechanical properties, and the inability to Meet the problems of industrial production and achieve the effects of flexible and convenient structural adjustment, shortening curing time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

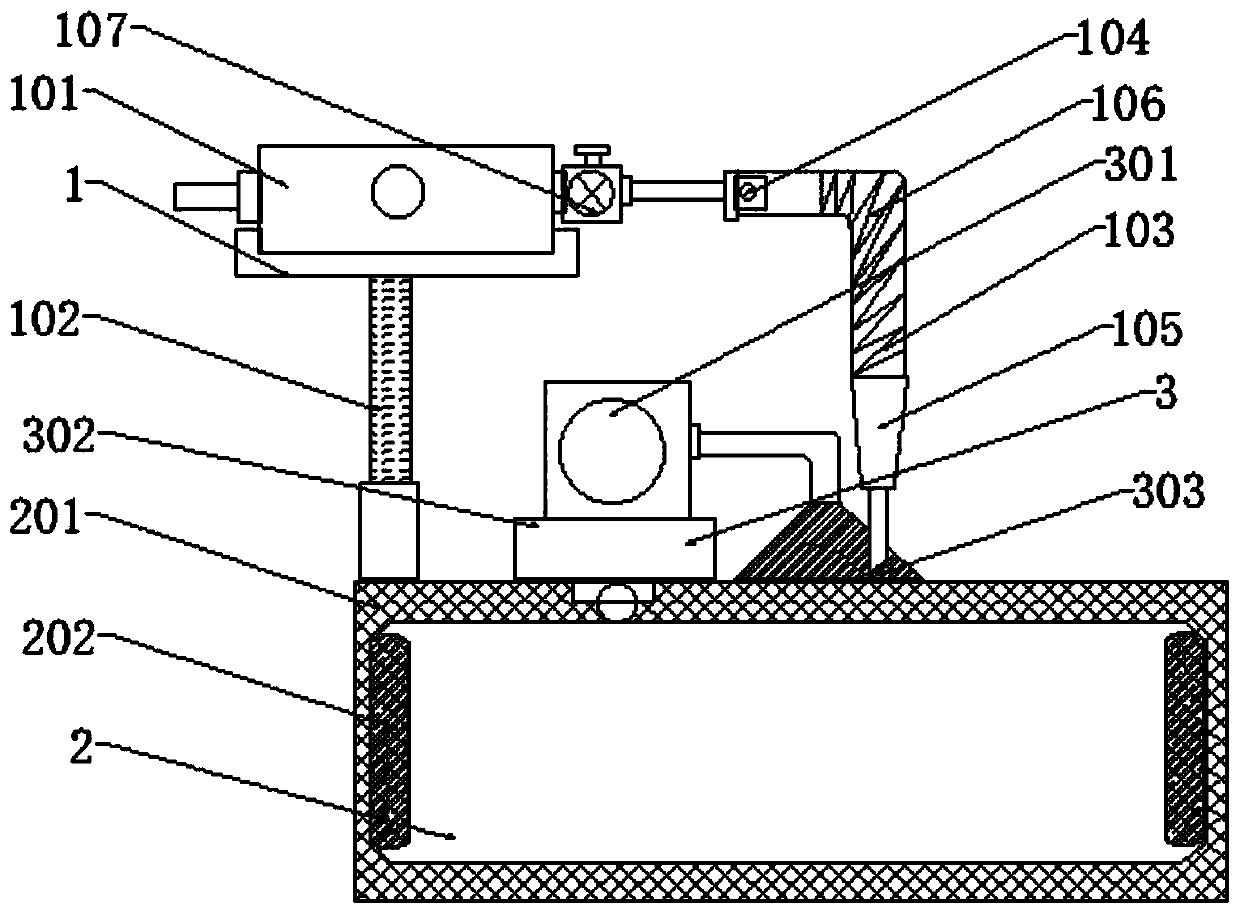

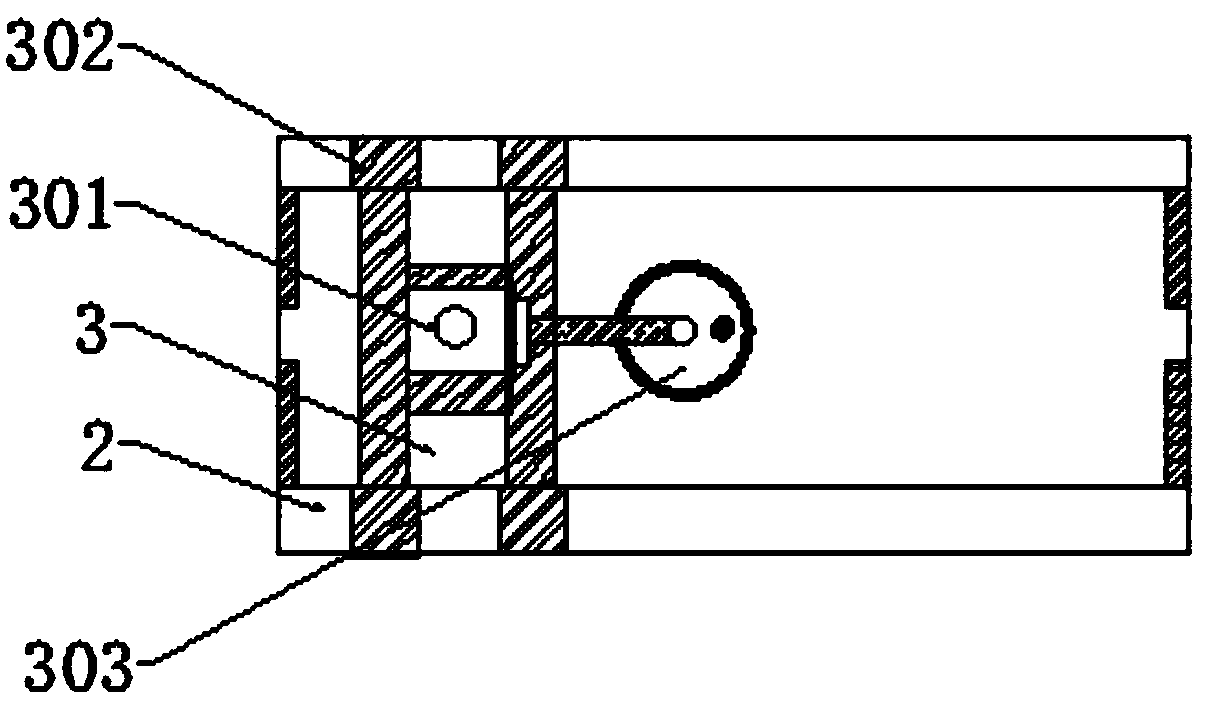

[0025] Such as figure 1 with figure 2 As shown, the present invention provides an automatic potting glue device for components used in the production of power modules, including a pouring mechanism 1, the glue outlet of the pouring mechanism 1 is directly above the pouring port of the component, and a curing Heating box 2, a vacuum defoaming mechanism 3 is also installed on the top side edge of the fixed heating box 2; the filling mechanism 1 is used to inject the liquid potting glue material into the inside of the component shell to be potted, because the filling process Uneven speed or pressure will cause many bubbles inside the perfused colloid. At this time, start the vacuum defoaming mechanism 3 to eliminate the vacuum bubbles, and then heat and cure the potted device through the curing heating box 2 to shorten the curing time. time.

[0026] Such as figure 1 As shown, the perfusion mechanism 1 includes a glue injection pump 101, the bottom of the glue injection pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com