Screening machine

A screening machine and funnel technology, applied in the field of screening machines, can solve the problems of low production efficiency, inability to completely separate, and inability to completely separate soybean impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

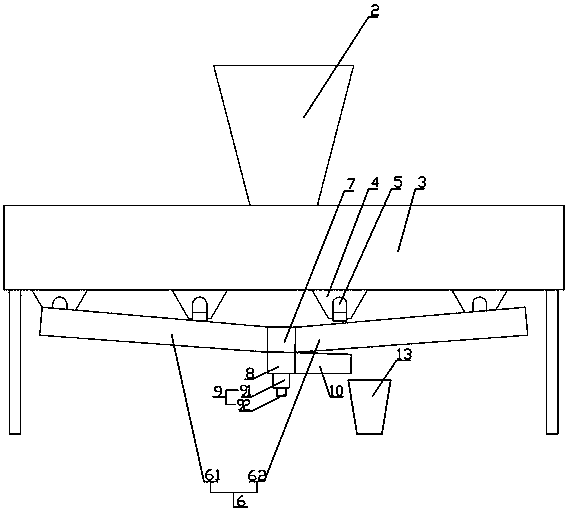

[0023] as attached figure 1 The present embodiment shown includes that soybeans and water enter the storage tank 3 through the feeding funnel 2, and the bottom of the storage tank 3 is connected with a discharge pipe 5, and the soybeans enter the chute 6 along the discharge pipe 5 driven by water, and the chute 6 is Set at a certain inclination angle, the discharge port of the chute 6 is connected to the feed port of the screening tank 8, the soybeans flow down along the chute 6 and enter the screening tank 8, after the impurities mixed in the soybeans are removed through the screening tank 8, the soybeans Enter the material receiving cylinder 13 along the conveying trough 10, from the soybeans entering the feeding funnel 2 to the final screening, the entire production process can completely separate the impurities in the soybeans, and can meet the purpose of separating impurities in soybeans in large quantities with high efficiency.

[0024] The bottom of the storage box 3 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com