Close-distance air jet purifier

A jet exhaust and gas technology, applied in the field of purifiers, can solve problems such as poor handling, high maintenance costs, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Figure 18 to Figure 25 Although the spray washing box group shown is simple in structure and takes up less space, it is difficult to clean when the small holes at the bottom of the jet row in the spray washing box are blocked, so we need to continue to optimize it;

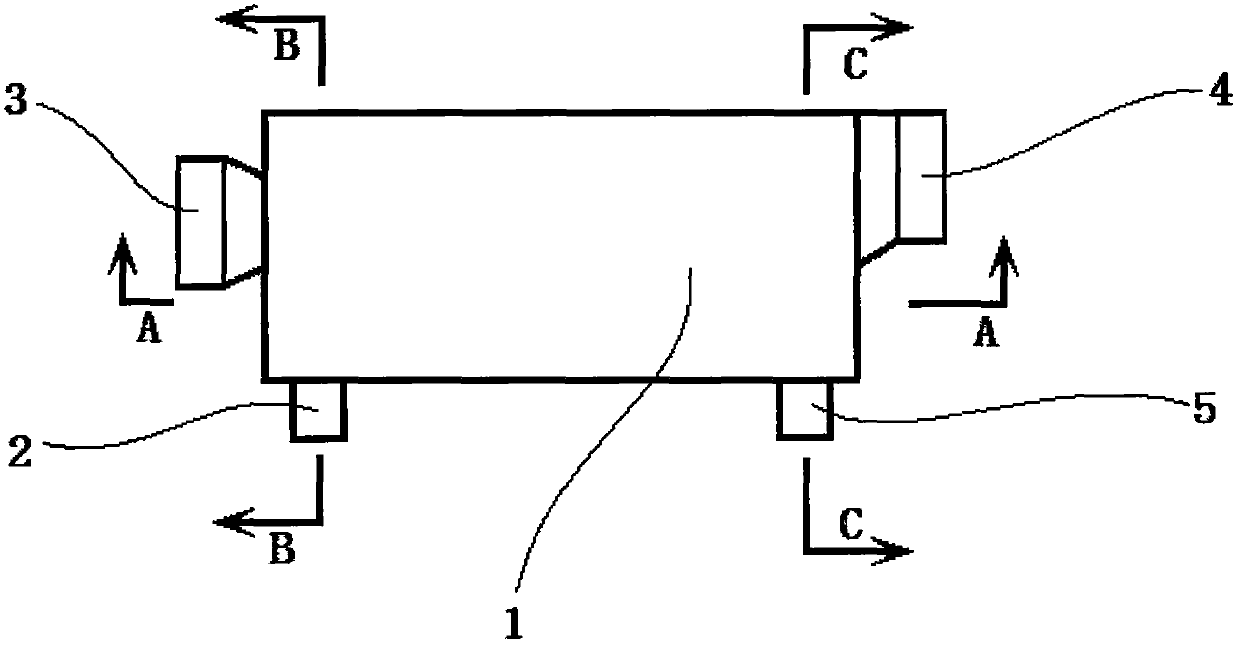

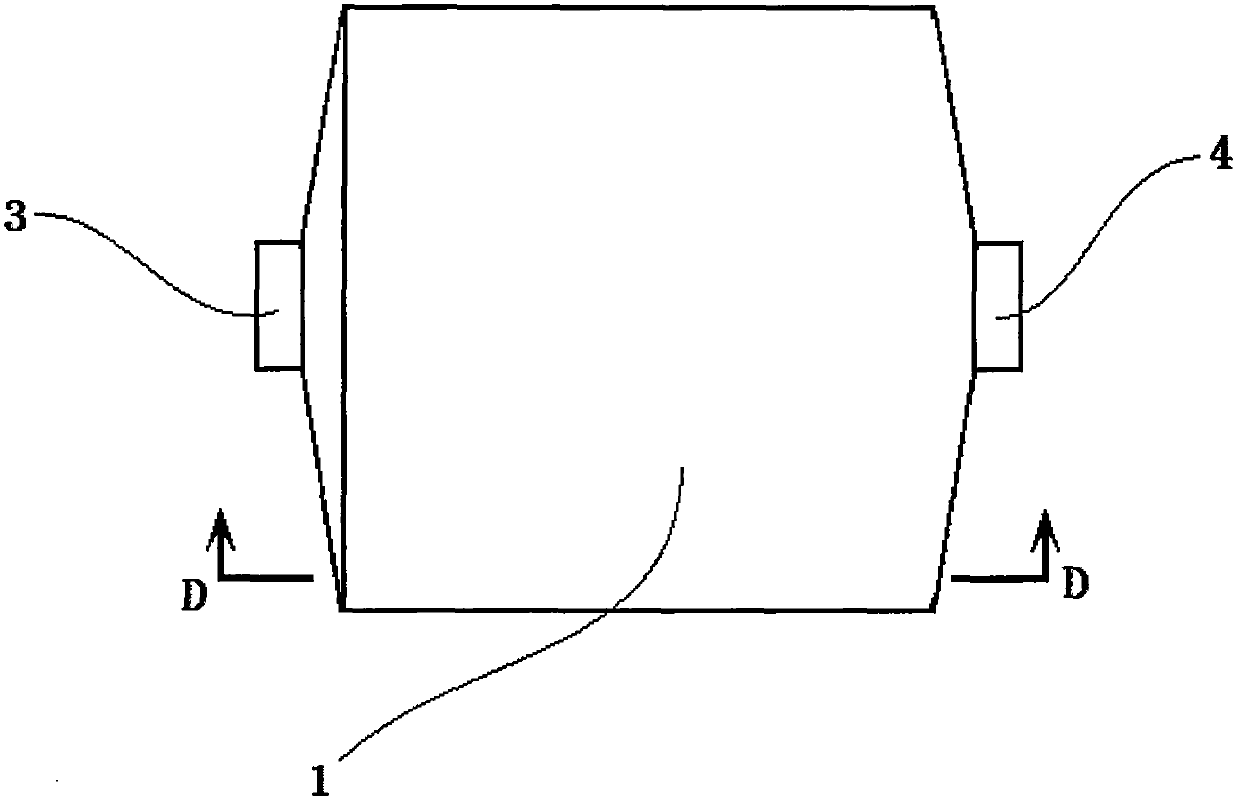

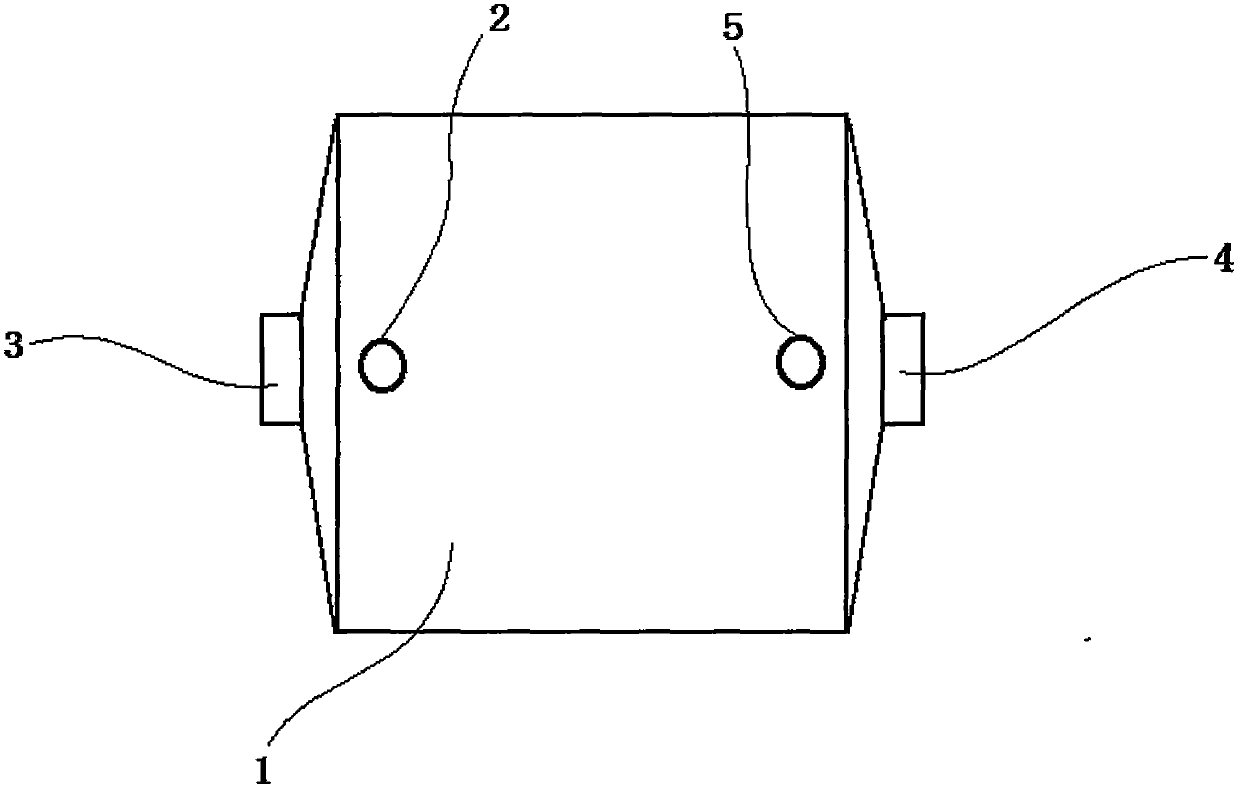

[0051] The first embodiment is a detachable close-range jet purifier;

[0052] See Figure 26 This is the design schematic diagram of the optimized spray washing box group. This is the second spray washing box group in the present invention. The biggest feature of the spray washing box group is that all the air jet rows can be removed for cleaning; The spray washing box group is composed of three parts: integrated box, first air jet platoon and general jet platoon; Figure 27 , 28, 29, 30, and 31 show an integrated box that integrates 5 spray tank shells, Figure 32 , 33 , 34 and 35 show the first air jet platoon. The first air jet platoon includes the intake pipe 13, the sealing cover 704, the bolt hole 712, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com