Locally conductive raised shirt collar fabric

A crisp and fabric technology, applied in the field of crisp shirt collar fabrics, can solve the problems of affecting the appearance of wearing, collar deformation, collar deformation, etc., and achieve the effects of optimizing production process, reducing production cost and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

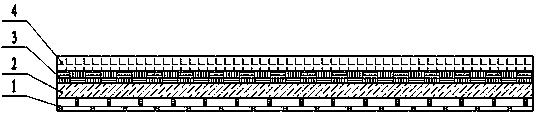

[0014] see figure 1 , a kind of partially conductive crisp shirt collar fabric, including a collar surface, and a first collar lining, a second collar lining and a lining material are arranged on the outside of the collar surface in sequence; the collar surface is woven with cotton fibers; the first collar surface The lining is made of woven fabric, which is straight silk full lining, and the yarn density of the knitted fabric is 28tex*28tex, and HDPE powder dot fusible interlining is used; the second collar lining is made of woven fabric, which is twill silk net lining, knitted fabric The yarn density is 14tex*13tex, using HDPE powder dot fusible interlining; the interlining is woven with holy hemp fiber.

[0015] A lining fabric layer is arranged on the back of the lining material. The lining fabric layer includes a fabric base layer. Several conductive units are distributed on the upper surface of the fabric base layer. The conductive units are fixedly connected to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com