Metal air battery with air pressure adjustment system

A technology of air pressure regulation system and metal-air battery, which is applied in the direction of fuel cell type half-cell and primary battery type half-cell, etc. control performance, extended battery life, good structural sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

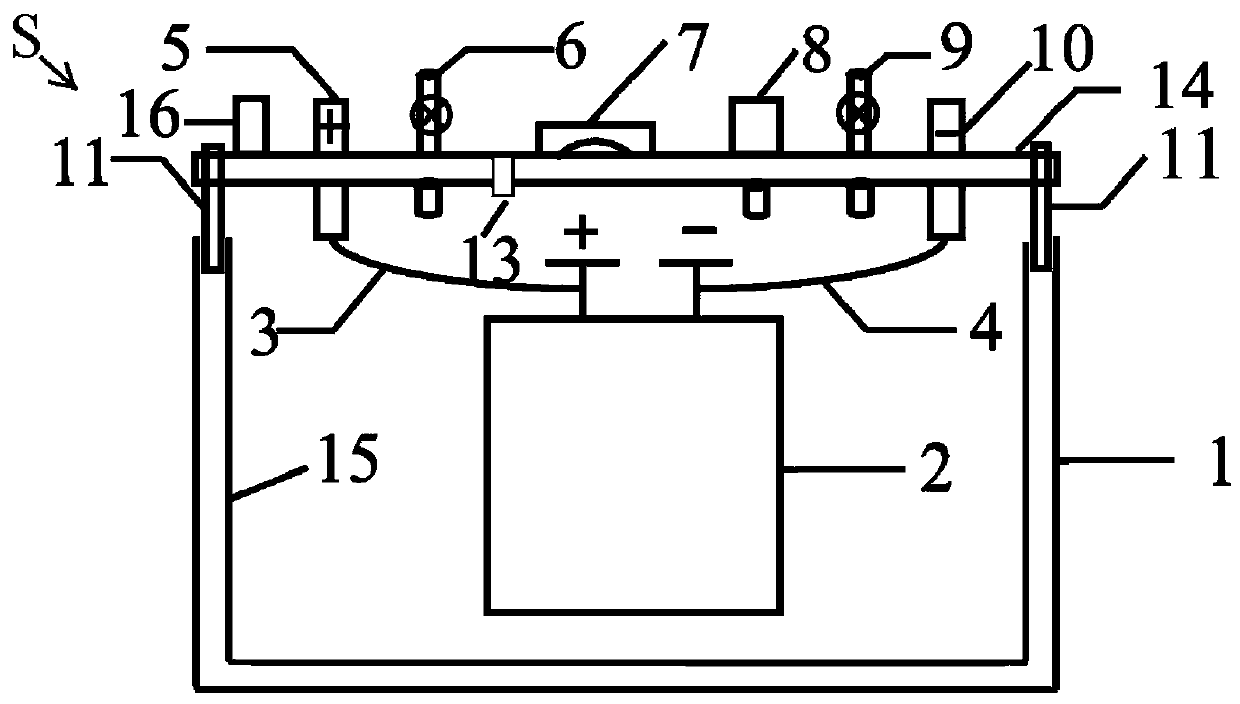

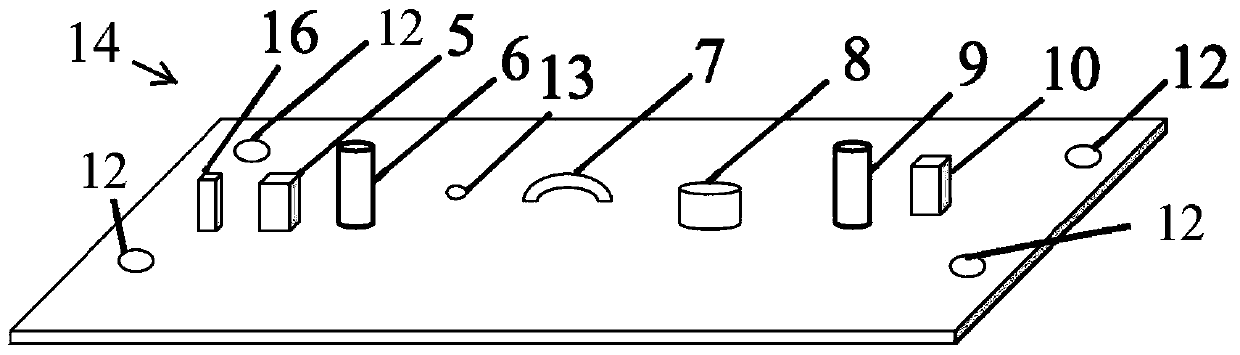

[0069] In this embodiment, the materials of the battery case 1 and the battery cover 14 are aluminum alloy, the surface is insulated, and the shape is rectangular with a size of 100×30 mm. 2 , the height of the battery case 1 is 160 mm. The pressure limit of safety valve 7 is set to 0.8 MPa.

[0070] The assembly process of the lithium-air battery is as follows: the battery cell 2 consisting of a lithium sheet (ie, the negative electrode), a separator, and an oxygen positive electrode is placed in the battery case 1 in an argon glove box. After connecting the positive and negative poles of the battery cell 2 to the positive and negative poles of the terminals 5 and 10 through the lead wires 3 and 4, vacuumize through the gas outlet valve 9 to discharge the remaining argon in the battery case 1, and then pass through the liquid injection hole 13 Introduce the electrolyte, and then pass high-purity oxygen through the intake valve 6. Then, the test circuit can be connected to t...

Embodiment 2

[0073] Another embodiment 2 according to the present invention will now be described. Please note that the relevant description of the same structure as the embodiment 1 in this embodiment 2 will be omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com