Adjusting device capable of realizing wire drawing and paying-off of copper wire

An adjustment device and wire drawing technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as economic loss, reel wall collision or friction, copper wire breakage, etc. Tube, avoid contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

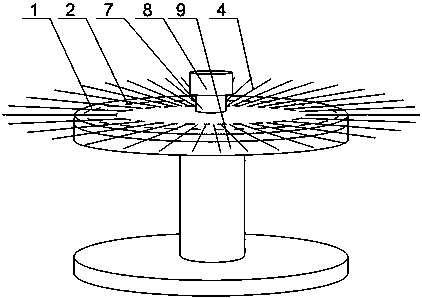

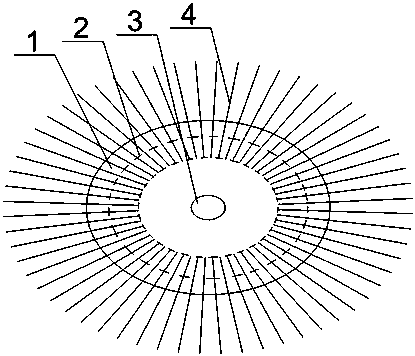

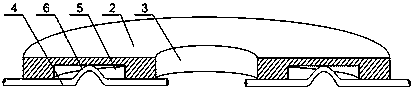

[0026] Such as Figure 1~Figure 4 As shown, the present embodiment includes a reel 9, a brush plate 1 and a plurality of resin threads 4, a fixing hole 3 is opened in the middle of the brush plate 1, and a plurality of resin threads 4 run along the brush plate 1. The radial direction of the brush plate 1 extends outward, and the upper surface of the brush plate 1 is bonded with a concentric and annular lower pressing plate 2 which covers a part of the resin thread 4, and The lower surface of the lower pressing plate 2 is provided with an annular groove 5, and a curved section 6 is provided on the plurality of thin resin wires 4, and the curved section 6 is placed in the annular groove 5 on the upper end surface of the reel 9. A positioning rod 7 is provided in the middle of the locating rod 7 which penetrates the fixing hole 3, and a guide groove 10 with a circular cross section is opened on both sides of the positioning rod 7, and a cylindrical counterweight 8 is slidably arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com