Test device and test method for simulating excavation and unloading under deep three-dimensional loading condition

A three-dimensional loading, excavation and unloading technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of uncompact design, large size, and large difference in stress paths, so as to ensure scientificity, accuracy, and reliability The effect of technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

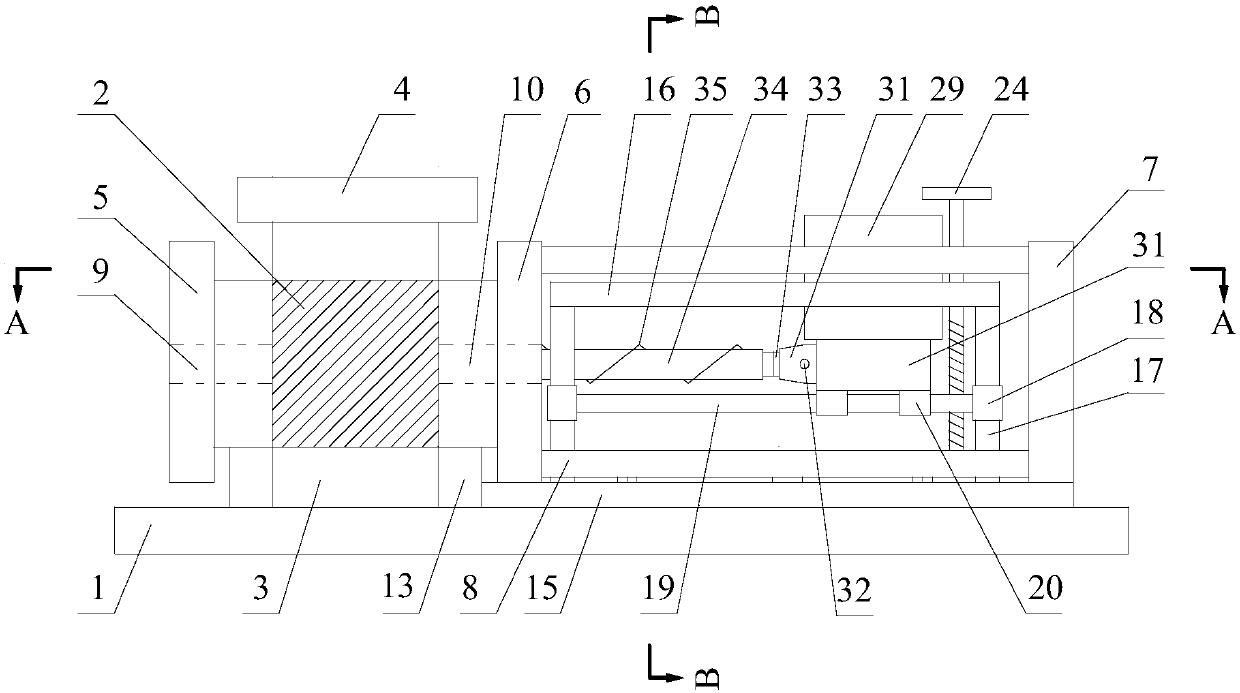

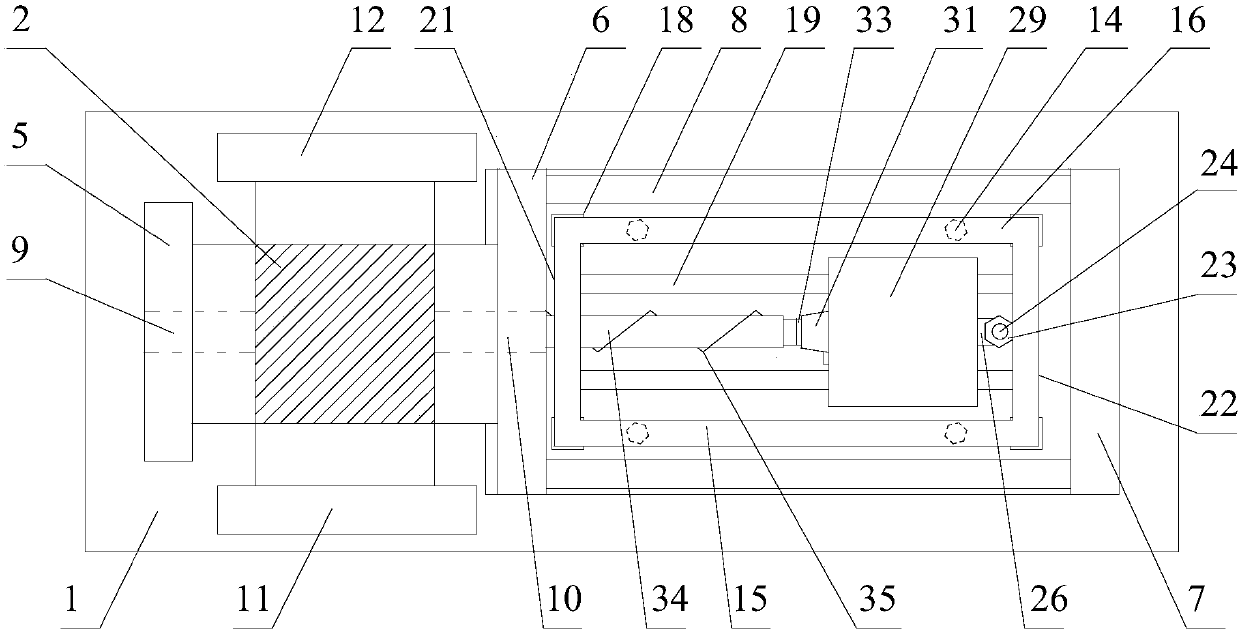

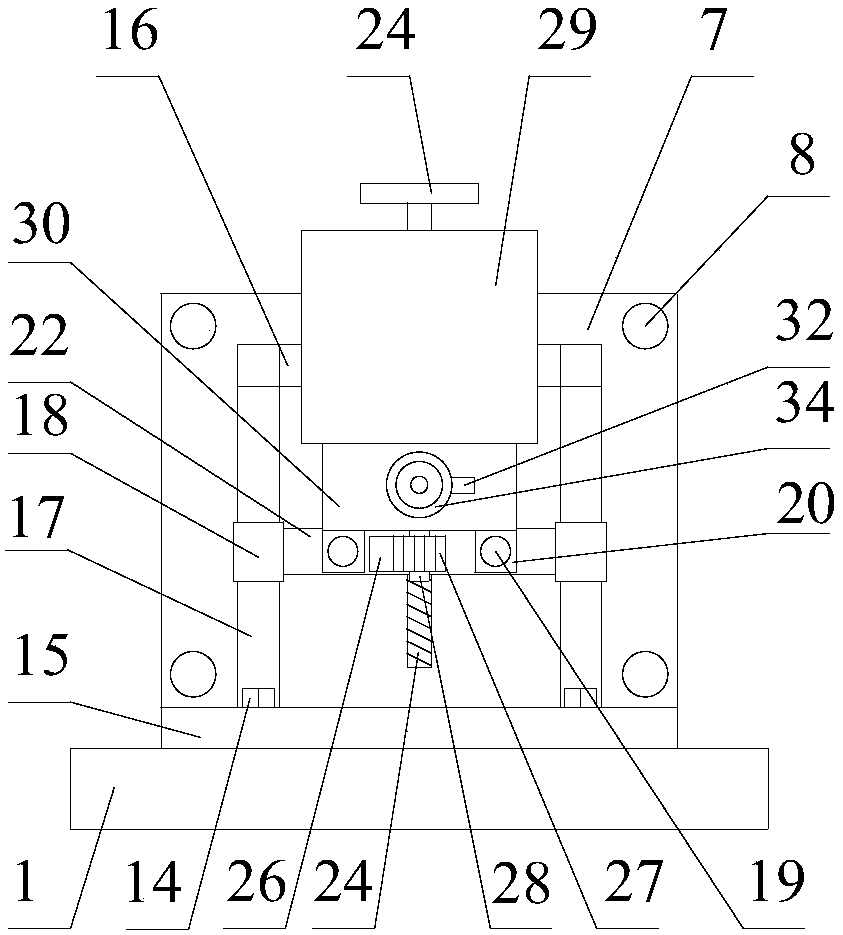

[0051] A drilling test method for simulating excavation and unloading of circular tunnels under three-dimensional deep loading conditions. A test device for simulating excavation and unloading of circular tunnels under deep three-dimensional loading conditions is carried out according to the following steps:

[0052] Step 1. Fix the device and perform three-dimensional loading on the rock sample 2: the drilling test device for excavation and unloading of a circular tunnel under the condition of simulating deep three-dimensional stress is fixed to the true triaxial test bench 1 by bolts 14, and then the real triaxial test bench 1 is used. The triaxial testing machine loads the rock sample 2 to the initial stress level;

[0053] Step 2. Install and adjust the position of the cutting bit 34: ensure that the central axes of the left round hole 9 and the right round hole 10 coincide, select a cutting bit 34 with a suitable diameter according to the test plan, and connect it with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com