Automotive blower assembly noise test system and method thereof

A technology for noise testing and blower, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., and can solve the problems of lack of scientificity, single evaluation parameters, inability to guarantee repeatability, objectivity and accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

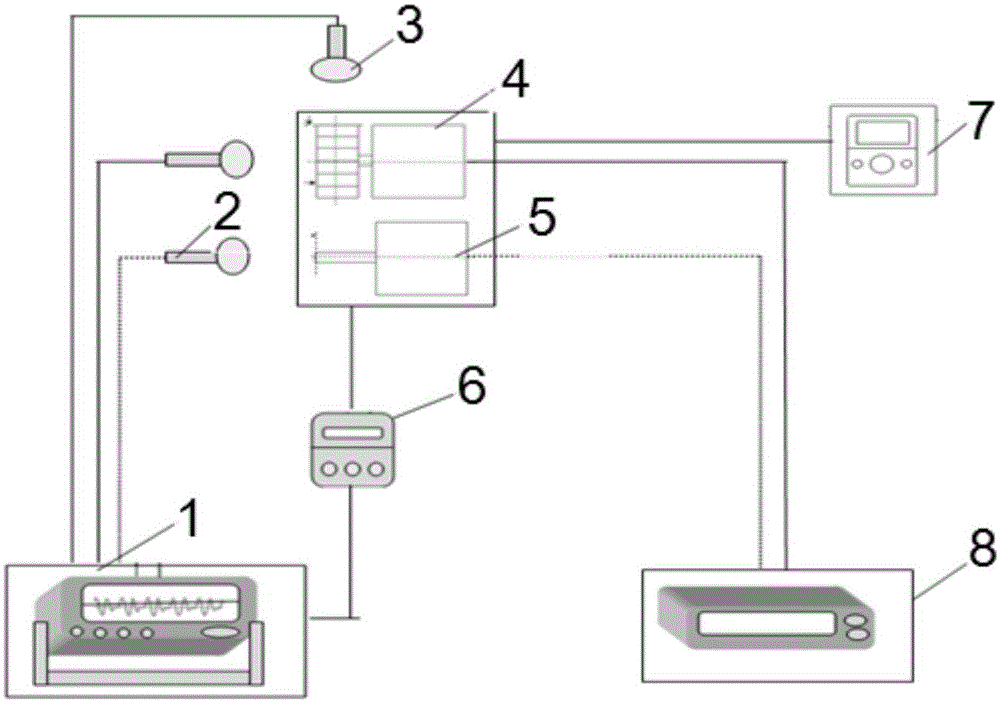

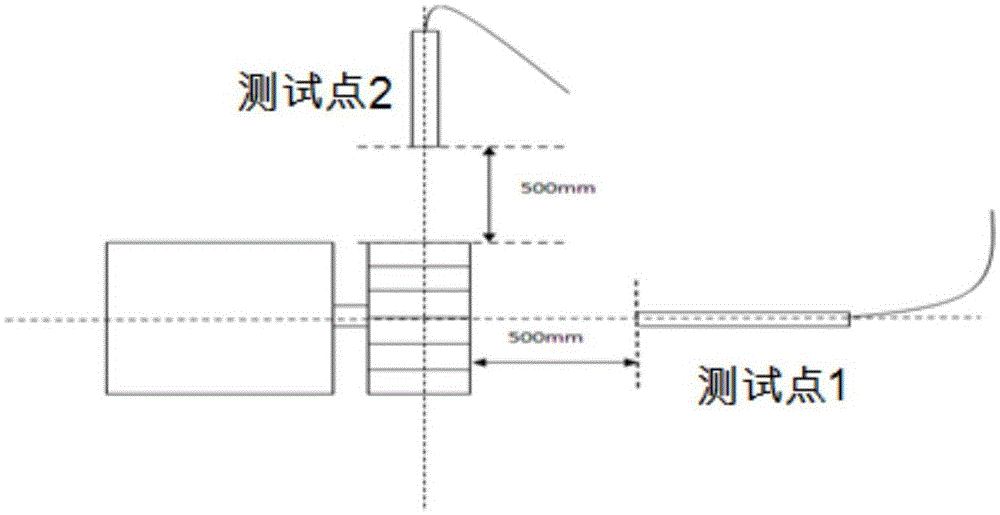

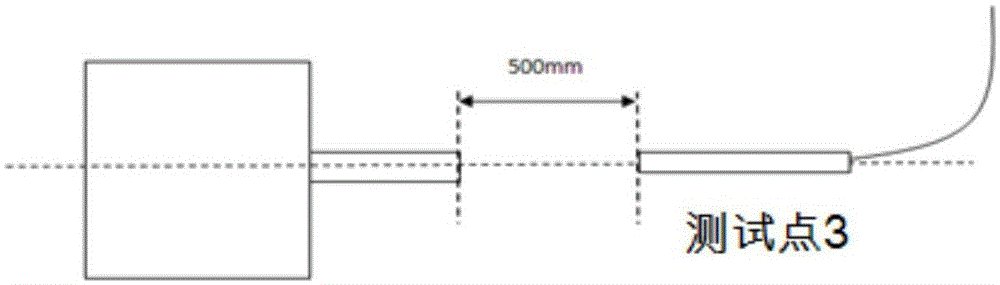

[0030] The present invention is a method for testing the noise of the blower / blower motor assembly 5 used in automobiles, in which the boundary conditions for sample installation, the location and quantity of measuring points, the test working conditions and the realization of the test working conditions, and the test hardware configuration are stipulated. , Collection, processing and analysis of test data.

[0031] System structure such as figure 1 As shown, above the position to be tested, there is an elastic rope for suspending the object to be tested, and a bracket for fixing the elastic rope. The elastic rope is suspended to ensure that the object under test will not shake due to its own rotation excitation after being restrained.

[0032] A free-field microphone 2 is arranged near the position to be measured, and the free-field microphone 2 is used to collect sound information. The information is sent to the data acquisition and analyzer 1, which is the equipment for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com