Vaporizing and heating system

A heating system and vaporization chamber technology, applied in lighting and heating equipment, heat exchanger types, indirect heat exchangers, etc. Good effect, high thermal efficiency and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

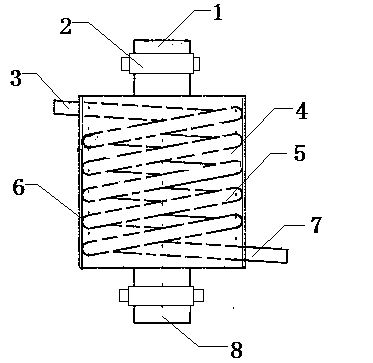

[0013] This embodiment provides a vaporization heating system, which is characterized in that: the vaporization heating system includes a liquefied gas inlet (1), a flange (2), an engine water inlet (3), a vaporization chamber (4), a heating Coil pipe (5), insulation layer (6), engine water outlet (7), liquefied gas outlet (8);

[0014] Among them: the liquid water in the engine flows through the engine water inlet (3), the heating coil (5), and the engine water outlet (7) in order to form circulating liquid water, and the liquefied gas flows through the liquefied gas inlet (1), vaporized chamber (4), liquefied gas outlet (8).

[0015] Both the liquefied gas inlet (1) and the liquefied gas outlet (8) are provided with flanges (2) for connection and installation.

[0016] The inside of the vaporization chamber (4) is provided with multiple vacuum insulation layers (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com